Silicon-nitrogen compound as well as preparation method and application thereof

A technology of silicon-nitrogen compounds and compounds, applied in a class of silicon-nitrogen compounds and its preparation and application fields, can solve the problems of acetic acid with irritating odor and metal corrosion, and achieve high reactivity, fast vulcanization speed and high reaction active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

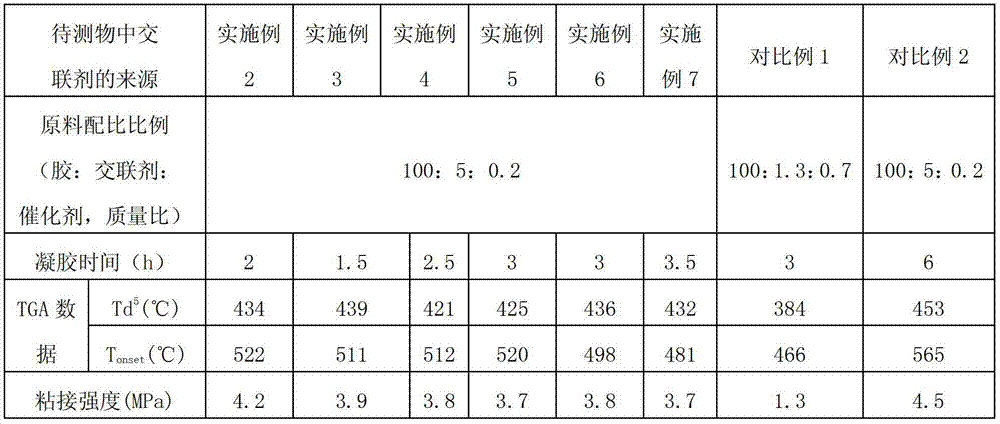

Examples

Embodiment 1

[0037] Embodiment 1, Cl 2 Si(Me)CH 2 CH 2 Si(Me 2 )OSi(Me 2 )CH 2 CH 2 Si(Me)Cl 2 Synthesis

[0038]Under nitrogen protection, add 30g of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane and 37g of methylhydrogendichlorosilane to a 150ml three-necked flask with a syringe, then add 50ml of tetrahydrofuran and 0.3g of Pt coordinated with 1,3-divinyl-1,1,3,3-tetramethyldisiloxane was used as a catalyst, and the temperature was raised to 50°C, stirred and refluxed for 12 hours, and excess methyl hydrogen was removed after the reaction Dichlorosilane and THF, distill the product under reduced pressure, collect the distillate at 110°C / 65Pa, and the yield is over 90%.

Embodiment 2

[0039] Embodiment 2, (Et 2 N) 2 Si(Me)CH 2 CH 2 Si(Me 2 )OSi(Me 2 )CH 2 CH 2 Si(Me)(NEt 2 ) 2 Synthesis

[0040] Add 4g of magnesium chips and 30g of Cl to a 250ml three-necked bottle with a syringe under nitrogen protection 2 Si(Me)CH 2 CH 2 Si(Me 2 )OSi(Me 2 )CH 2 CH 2 Si(Me)Cl 2 , then add 80ml of n-hexane as solvent, stir and heat up to 50°C, slowly inject 30g of diethylamine into the flask with a syringe, keep the solution turbid, the whole process lasts about 1h, after adding diethylamine, heat up to 75°C React overnight (about 12h). After the reaction was completed, the product was obtained by filtering, removing the solvent and unreacted diethylamine, and the yield was 85%.

Embodiment 3

[0041] Embodiment 3, (M 2 N) 2 Si(Me)CH 2 CH 2 Si(Me 2 )OSi(Me 2 )CH 2 CH 2 Si(Me)(NMe 2 ) 2

[0042] Add 4g of magnesium chips and 30g of Cl to a 250ml three-necked bottle with a syringe under nitrogen protection 2 Si(Me)CH 2 CH 2 Si(Me 2 )OSi(Me 2 )CH 2 CH 2 Si(Me)Cl 2 , and then add 80ml of chloroform as a solvent, stir and heat up to 50°C, then slowly pass dimethylamine into the three-necked bottle, keep the solution turbid, and continue to pass dimethylamine for 15h. After the reaction was completed, the product was obtained by filtering to remove the solvent and unreacted dimethylamine, and the yield was 87%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com