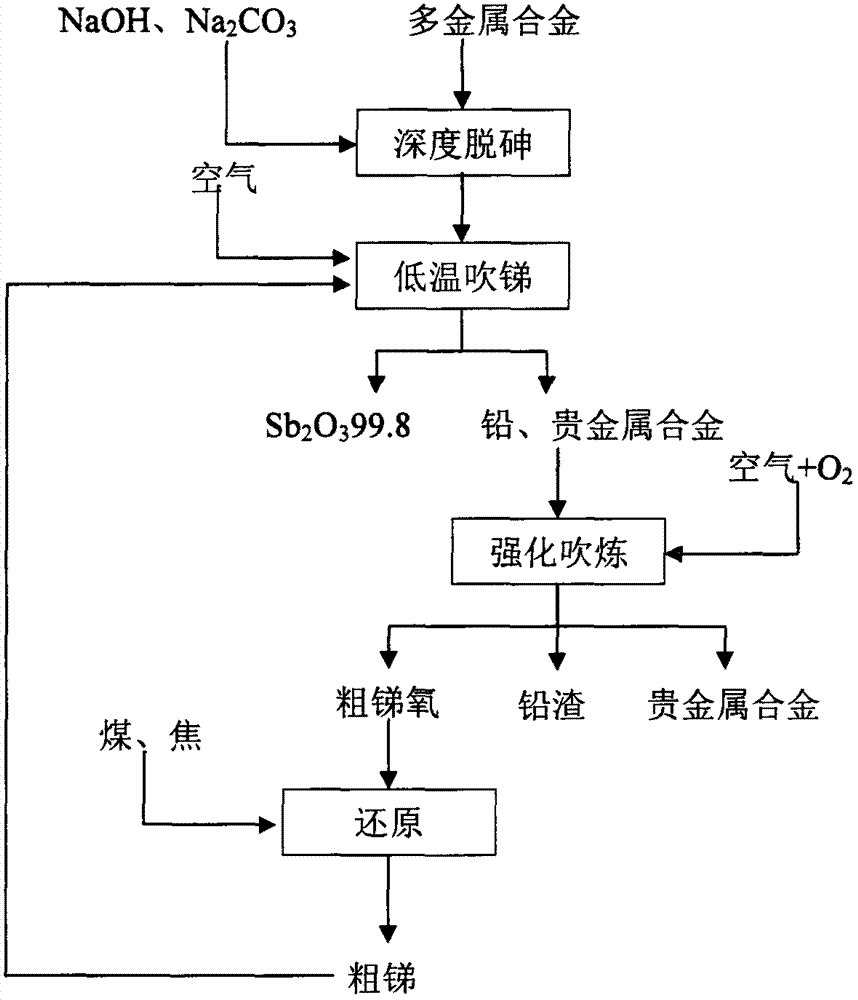

Treatment method for polymetallic alloy formed by arsenic-lead-antimony and noble metal

A processing method and precious metal technology, applied in the direction of improving process efficiency, can solve the problem of difficulty in directly obtaining qualified antimony white product precious metal alloy, etc., and achieve the effect of reducing the amount of precious metal volatilization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

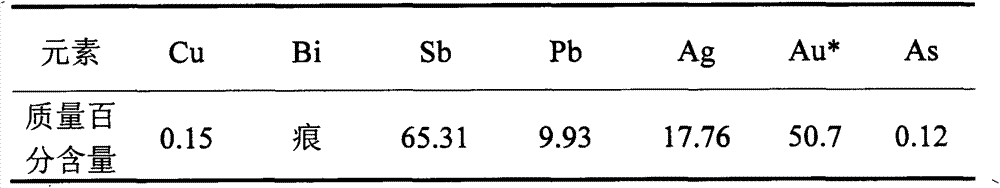

[0047] Take 5000kg of lead anode slime whose composition is shown below to reduce the obtained polymetallic alloy.

[0048] Table 1 Raw material composition / %

[0049]

[0050] Note: *--g / t

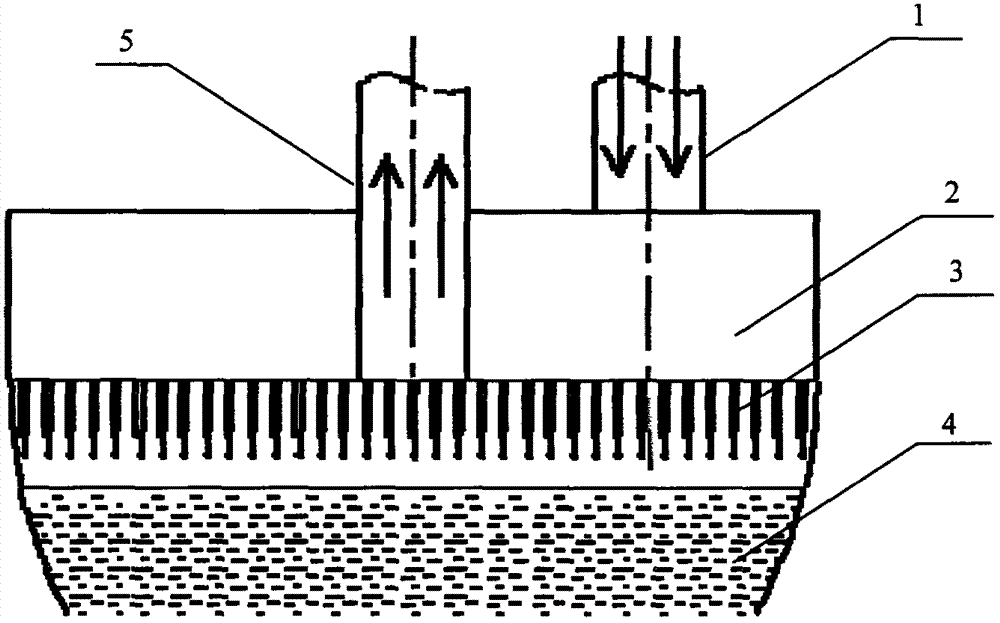

[0051] Under the condition of 600~650℃, add NaOH according to 1.2 times of the theoretical amount, and blow air into it for 1.5~2h to oxidize, and the arsenic can be removed to 0.03%, which is used for the next step of antimony white conversion. Under the condition of 800~850℃, in figure 2 The antimony white is blown in the road shown, and the antimony grade at the end of the blowing is controlled to be 10%, and the quality of the obtained antimony white is shown in Table 2.

[0052] Table 2 The mass of antimony white in comprehensive condition test / %

[0053]

[0054] The product quality reaches the Sb in GB / T4062-1998 2 o 3 99.8 requirements.

[0055] The residual alloy composition obtained after blowing is shown in Table 3.

[0056] Table 3 Composition of rich and noble le...

Embodiment 2

[0065] Take 30 tons of the alloy whose composition is shown in Table 5, under the condition of 600-650°C, add NaOH according to twice the theoretical amount, and oxidize it by blowing air for 6 hours, and remove the arsenic to 0.04%, which will be used in the next step of antimony white casting .

[0066] Table 5 Raw material composition / %

[0067]

[0068] Note: *--g / t

[0069] At 880°C, at figure 2 The antimony white is blown in the road shown, and the antimony grade at the end of the blowing is controlled to be 9%, and the quality of the obtained antimony white is shown in Table 6.

[0070] Table 6 Mass / % of antimony white in comprehensive condition test

[0071]

[0072] The product quality reaches the Sb in GB / T4062-1998 2 o 3 99.8 requirements.

[0073] The residual alloy composition obtained after blowing is shown in Table 7.

[0074] Table 7 Composition of rich and noble lead obtained from blowing / %

[0075]

[0076] Note: *--g / t

[0077] Put the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com