Diffusion bonding method without external pressure for Ti (C, N)-based metal ceramic and steel

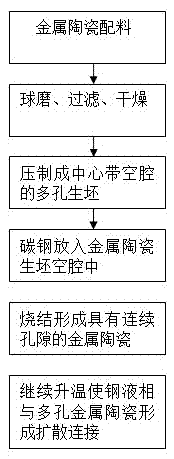

A cermet and diffusion joining technology, applied in the field of welding, can solve the problems of short diffusion time between castings and surface ceramic layers, unfavorable surface densification and sufficient diffusion, large thermal residual stress, etc. The effect of sufficient diffusion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Example 1: The particle size of Ni in the raw materials used to prepare Ti(C,N)-based cermet is 1.5μm, the particle size of Co is 1.3μm, and the particle size of Fe is 2.0μm, Mo 2 The particle size of C is 1.5μm, TiC 0.7 N 0.3 The particle size is 1.8μm. The weight percentage of Ti(C,N)-based cermet components is 5wt% of Ni, 5wt% of Co, 5wt% of Fe, Mo 2 C accounts for 9wt%, TiC 0.7 N 0.3 For the margin. The ball milling medium of the cermet mixed powder is No. 120 solvent oil, the dosage is 400ml, the ball milling speed is 60r / min, the grinding time is 48h, the grinding ball is WC-8wt%Ni cemented carbide ball with Φ6mm, and the weight ratio of the ball to material It is 5:1, adding 10wt% paraffin, 0.5wt% oleic acid, 0.5wt% Tween 80 as composite forming agent; after ball milling, the cermet slurry is filtered with 400 mesh, and the vacuum drying temperature is 85℃. The vacuum degree is 3Pa; the pressure of the cermet porous green body is 200MPa during pressing, the cavit...

example 2

[0018] Example 2: The particle size of Ni in the raw materials used for the preparation of Ti(C,N)-based cermet is 1.2μm, the particle size of Co is 1.5μm, and Mo 2 The particle size of C is 1.8μm, TiC 0.7 N 0.3 The particle size is 1.4μm; the weight percentage of Ti(C,N)-based cermet is 20wt% Ni, 8wt% Co, Mo 2 C accounts for 12wt%, TiC 0.7 N 0.3 The balance; the ball milling medium of the cermet mixed powder is 120# solvent naphtha, the dosage is 200ml, the ball milling speed is 90r / min, the grinding time is 36h, and the grinding ball is a WC-8wt%Ni cemented carbide ball with Φ8mm. The ball-to-material weight ratio is 10:1, 5wt% paraffin wax, 1wt% oleic acid, 2% Tween 80 are added as composite forming agent; after ball milling, the cermet slurry is filtered with 400 mesh, and the vacuum drying temperature is 95 ℃, the vacuum degree is 3 Pa; the pressure of the porous metal ceramic green body is 100MPa, the cavity volume is fixed, and the porosity of the green body is 75% by ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com