Preparation method of polyacid based tubular monocrystal microreactor

A micro-reactor, tubular technology, applied in the field of polyacid-based tubular single-crystal micro-reactor preparation, can solve the problem of lack of crystal structure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

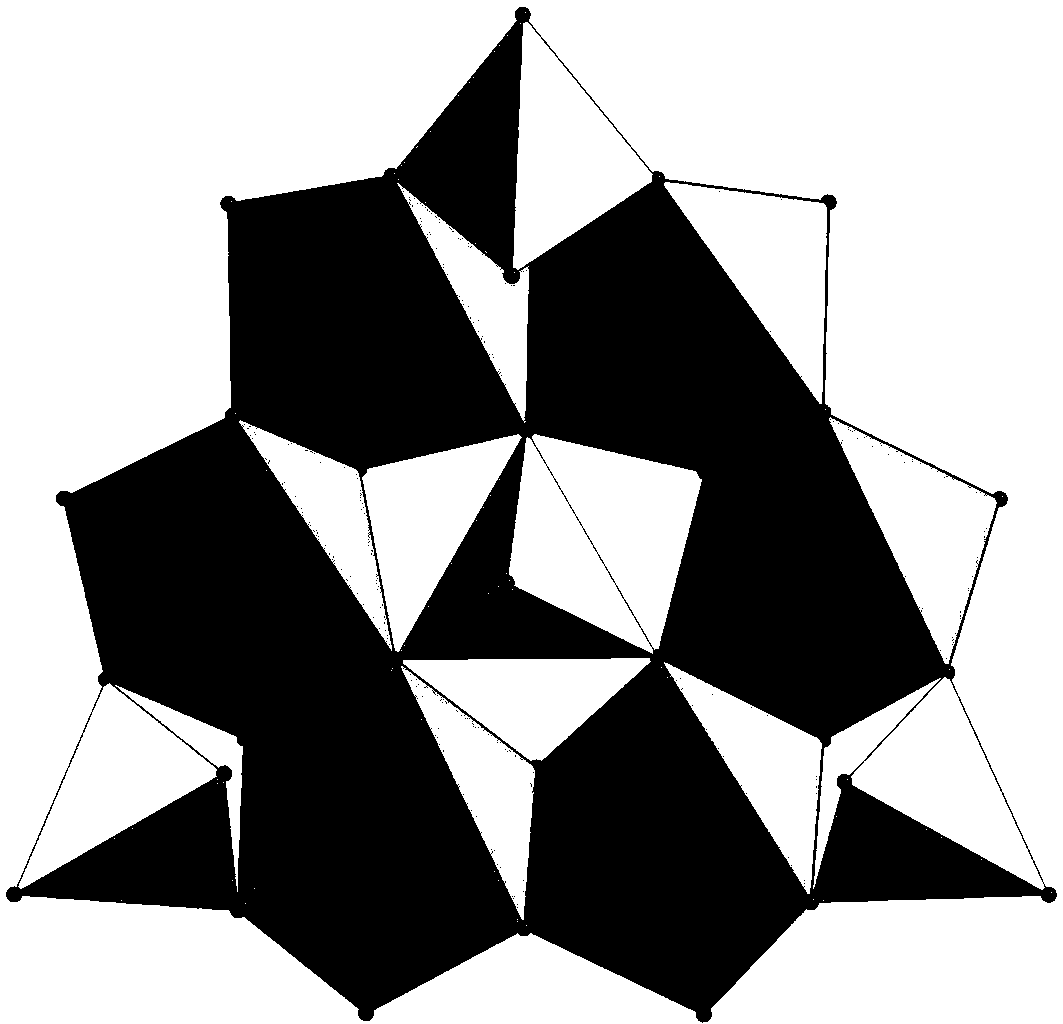

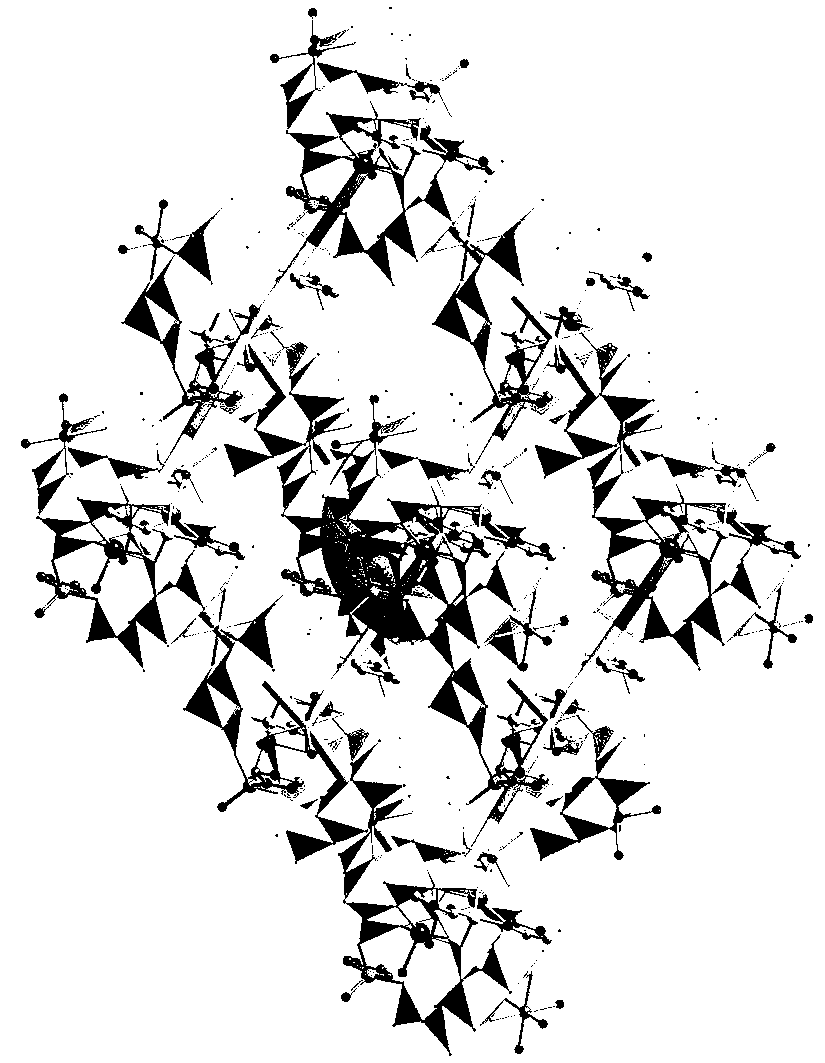

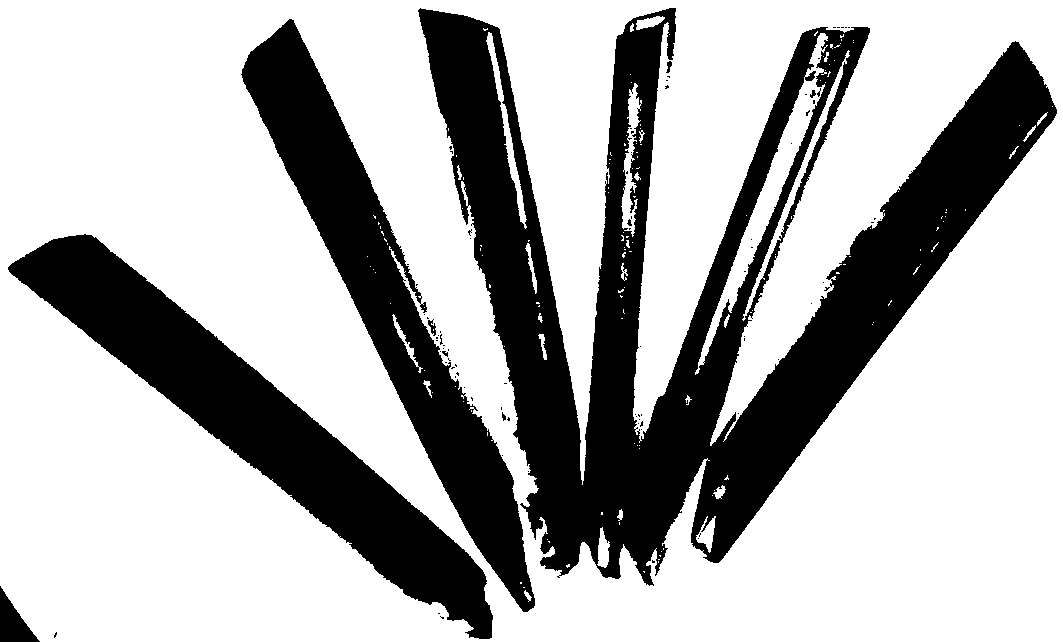

[0020] A polyacid-based tubular single-crystal microreactor whose chemical composition is: Mn[Zn(im)] 2 {[Na(H 2 O)] 2 [Mn(H 2 O) 2 ][Zn(im) 2 ][P 4 Mo 6 o 31 h 6 ] 2} 8H 2 O.

[0021] Preparation method: Add molybdate and phosphorous acid in distilled water at a molar ratio of 5:1, and use hydrochloric acid (6 mol L -1 ) to adjust the pH of the mixture between 5 and stir for 20 minutes. Imidazole (im), manganese chloride, and zinc acetate were sequentially added to the mixture and stirred for 20 minutes. Then put it into a high-pressure reaction kettle, raise the temperature to 170°C, keep it warm for 60 hours, then lower it to room temperature at a speed of 1-10°C / min, and filter to obtain a polyacid-based tubular single crystal microreactor.

Embodiment 2

[0023] A polyacid-based tubular single-crystal microreactor whose chemical composition is: Mn[Zn(im)] 2 {[Na(H 2 O)] 2 [Mn(H 2 O) 2 ][Zn(im) 2 ][P 4 Mo 6 o 31 h 6 ] 2} 8H 2 O.

[0024] Preparation method: Add molybdate and phosphorous acid in distilled water at a molar ratio of 5:1, and use hydrochloric acid (6 mol L -1 ) to adjust the pH of the mixture to 3 and stir for 30 minutes. Imidazole (im), manganese chloride, and zinc acetate were sequentially added to the mixture and stirred for 30 minutes. Then put it into a high-pressure reaction kettle, raise the temperature to 160°C, keep it warm for 48 hours, then lower it to room temperature at a speed of 1-10°C / min, and filter to obtain a polyacid-based tubular single crystal microreactor.

Embodiment 3

[0026] A polyacid-based tubular single-crystal microreactor whose chemical composition is: Mn[Zn(im)] 2 {[Na(H 2 O)] 2 [Mn(H 2 O) 2 ][Zn(im) 2 ][P 4 Mo 6 o 31 h 6 ] 2} 8H 2 O.

[0027] Preparation method: add molybdate and phosphorous acid in distilled water at a molar ratio of 5:1, and use hydrochloric acid (6 mol L -1) to adjust the pH of the mixture at 6 and stir for 30 minutes. Imidazole (im), manganese chloride, and zinc acetate were sequentially added to the mixture and stirred for 30 minutes. Then put it into a high-pressure reaction kettle, raise the temperature to 180°C, keep it warm for 72 hours, then lower it to room temperature at a speed of 1-10°C / min, and filter to obtain a polyacid-based tubular single crystal microreactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com