Purifying treating agent for organic reaction waste liquor and treating method

A purification treatment and organic reaction technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems that the reactants cannot be recycled and the cost of the treatment process is high, and achieve repeated recycling, Excellent adsorption performance and purification performance, and the effect of simplifying the purification steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

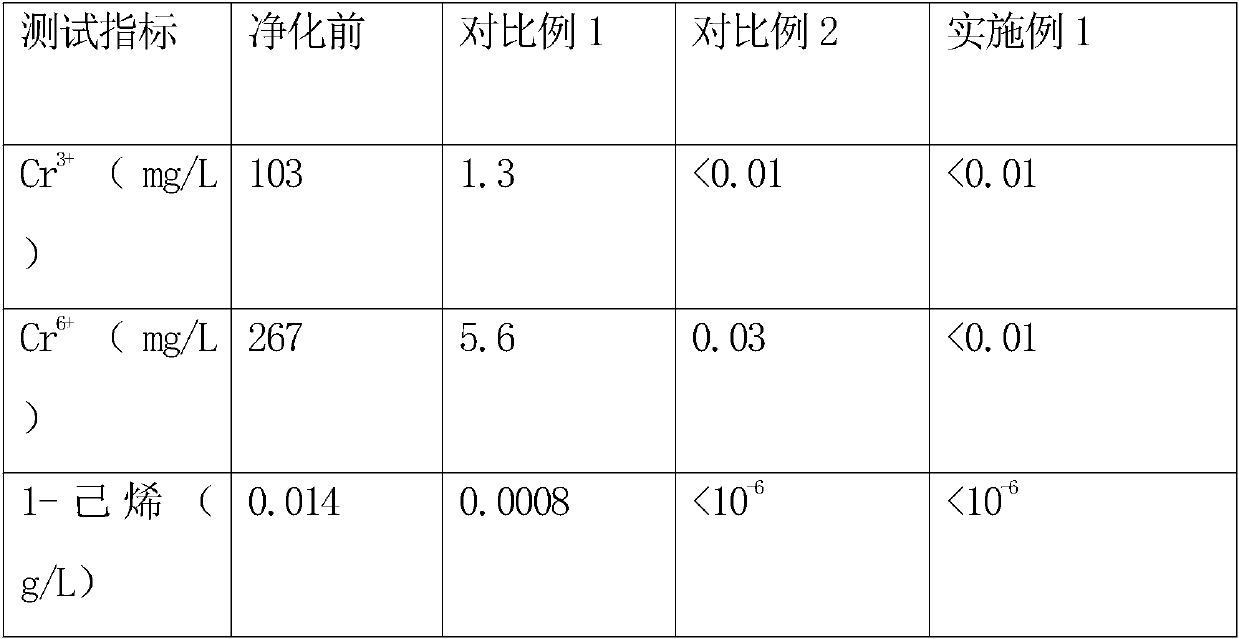

Examples

Embodiment 1

[0044] A kind of purification treatment agent of organic reaction waste liquid, described purification treatment agent is made through the following steps:

[0045] (1) Sodiumization of montmorillonite, put 1kg montmorillonite into 2.5L distilled water, mechanically stir for 1h, then slowly add 0.36kg sodium hexametaphosphate therein, mix uniformly to obtain sodium montmorillonite solution;

[0046] (2) Get 425g ferric chloride hexahydrate and 305g ferrous chloride tetrahydrate, place in 2.5L distilled water, then heat to 35-45 degrees centigrade and stir evenly to obtain molten iron;

[0047] (3) Take 10 g of cationic starch and add it to 25 ml of deionized water, and use high-pressure homogenization for 3-4 hours to obtain a cationic complex liquid; wherein the molecular weight of the cationic starch is 500,000 to 2,000,000 g / mol; the degree of substitution is 0.5-1; the charge density 3-6meq / g.

[0048](4) Slowly add the iron obtained in step (2) to the sodium montmorillon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com