Multifunctional interface polymer cement sheet and manufacturing method thereof

A polymer and multi-functional technology, applied in the direction of building materials, etc., can solve problems such as poor bonding, falling off of insulation boards, decorative boards, and difficult quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

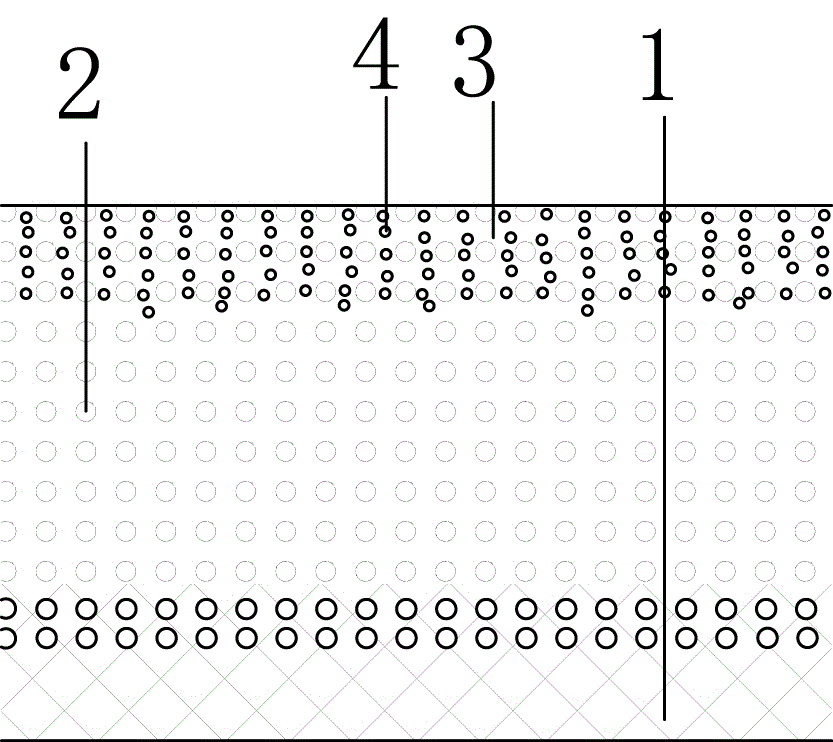

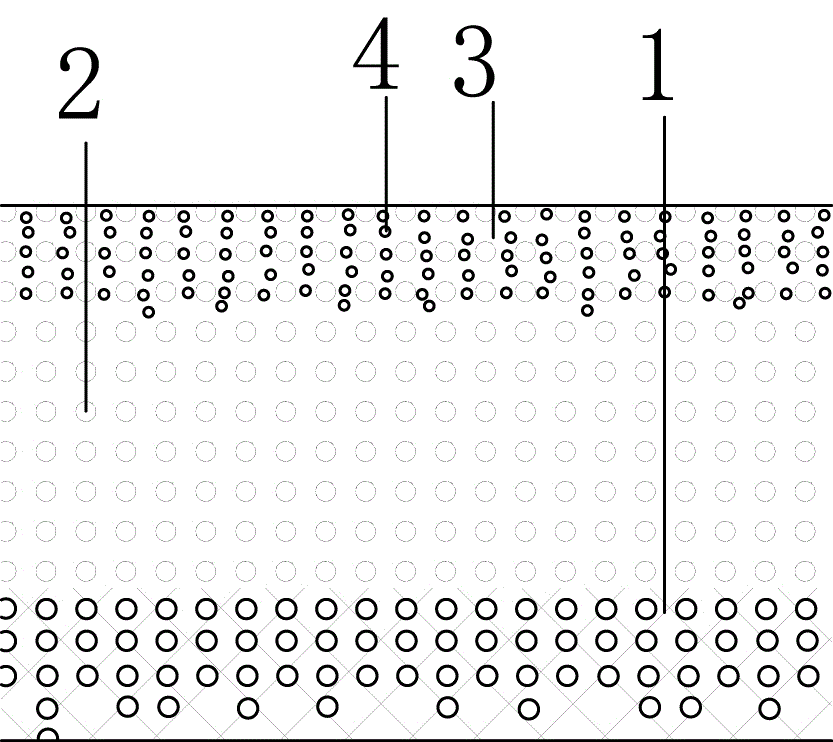

Image

Examples

Embodiment 1

[0064] Step 1: Make flexible polymer cement microbubble slurry. Standby: mix 35 parts by weight of elastic high molecular polymer water emulsion (such as BA-310T), 35 parts by weight of cement (such as ordinary Portland cement), and inorganic powder ( Such as quartz sand or powder) 29 parts by weight, air-entraining agent (such as sodium dodecyl benzene sulfonate) 1.0 parts by weight, add to the mixing kettle in the above order, keep stirring, when the volume of the material increases by 6%, it is the end of the stirring , Stop the stirring, prepare the flexible polymer cement micro-bubble slurry, and the slurry is barreled and left in the process for later use.

[0065] The detection method for increasing the volume of the material by 6%: Take a sample from the kettle, and pour 100g of the sample into a 100ml graduated cylinder. When the sample volume reaches 76-80ml, it can be regarded as reaching the target requirement.

[0066] Step 2: Introduce the non-woven fabric to the clot...

Embodiment 2

[0069] Step 1: Make flexible polymer cement microbubble slurry. Standby: mix 50 parts by weight of elastic polymer emulsion (such as GD-3400), 28.5 parts by weight of cement (such as aluminum sulfate cement), and inorganic powder (such as :Inorganic powder made from quartz sand or powder: light calcium carbonate=1:0.3-0.6) 21 parts by weight, air-entraining agent (such as alkylphenol polyoxyethylene ether) 0.5 parts by weight, add in the above order When the volume of the material increases by 7%, it is the end of the mixing. The mixing is stopped, and the flexible polymer cement micro-bubble slurry is prepared. The slurry is barreled and left for use.

[0070] The detection method for a 7% increase in the volume of the material: Take out the sample from the kettle and pour 100g of the sample into a 100ml graduated cylinder. When the sample volume reaches 78-82ml, it can be regarded as reaching the target requirement.

[0071] The second step: Introduce the non-woven fabric to the ...

Embodiment 3

[0074] Step 1: Make flexible polymer cement micro-bubble slurry. Standby: 40 parts by weight of elastic high molecular polymer water emulsion (such as GD-3638 and BLJ-950 in any proportion); cement (such as magnesium oxychloride cement) 31 parts by weight; inorganic powder (for example, inorganic powder made according to the ratio of quartz sand or powder: kaolin = 1:0.4-0.5) 28 parts by weight; air-entraining agent (for example, fatty alcohol polyoxyethylene ether sodium sulfate) 1.0 The parts by weight are added to the mixing kettle in the above order and stirred continuously. When the volume of the material increases by 10%, it is the end of the stirring. Stop stirring to prepare a flexible polymer cement microbubble slurry. The slurry is barreled and left in the process for later use. .

[0075] The detection method for a 10% increase in material volume: Take a sample from the kettle, and pour 100g of the sample into a 100ml graduated cylinder. When the sample volume reaches ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com