Low-melting-point metal liquid rheostat

A low-melting-point metal and liquid rheostat technology, applied in the direction of liquid resistors, etc., can solve the problems of travel switch casing corrosion, poor contact of conductive contacts, and increased operation complexity, and achieve stable operation, light weight, and stable physical and chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

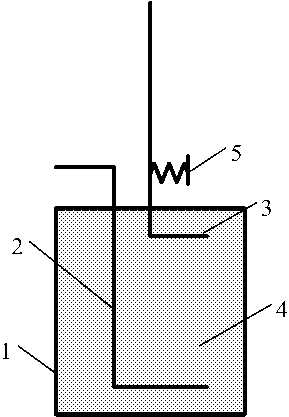

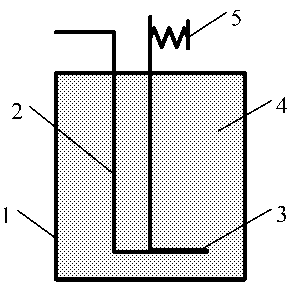

[0030] Embodiment 1 shows a typical application of the low melting point metal liquid varistor of the present invention. Fig. 1 is a schematic structural diagram of a low-melting-point metal liquid rheostat when the motor starts; Fig. 2 is a structural schematic diagram of a low-melting-point metallic liquid rheostat when the motor starts.

[0031] As shown in FIG. 1 and FIG. 2 , the low-melting-point metal liquid varistor of this embodiment is composed of a housing 1 , a static electrode plate 2 , a moving electrode plate 3 , a low-melting-point metal 4 , and a screw rod 5 .

[0032] The housing 1 is made of stainless steel;

[0033] The static electrode plate 2 is fixed in the housing 1 and made of copper;

[0034] The moving electrode plate 3 is parallel to the static electrode plate 2 and is made of copper;

[0035] The low-melting-point metal 4 is filled in the housing 1, and the low-melting-point metal 4 is a gallium-indium-tin-bismuth-zinc-tin alloy;

[0036] The scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com