Preparation method and application of three-dimensional porous electrode material

An electrode material, three-dimensional porous technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as low electron transfer efficiency, and achieve the effects of enhancing electron transfer efficiency, increasing adhesion, and improving battery power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of a three-dimensional porous electrode material, comprising the following steps:

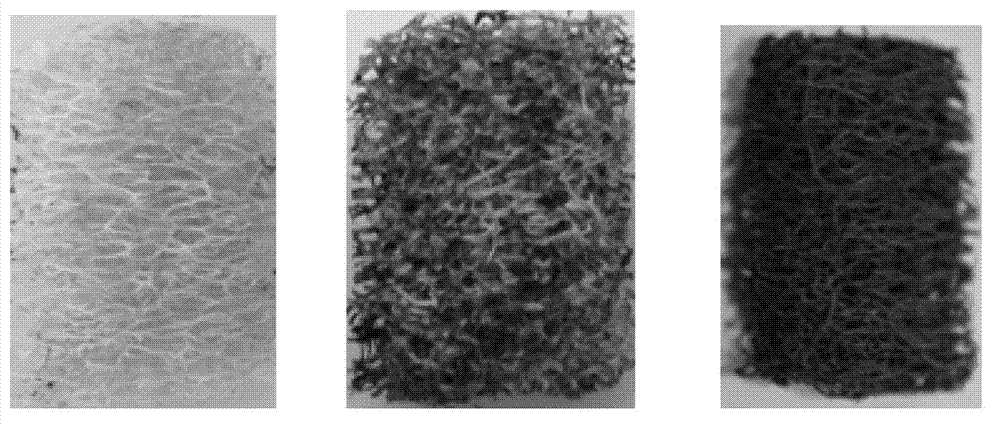

[0028] 1) Take the loofah and cut it into 2.0cm×1.5 cm×0.5 cm (length×width×thickness, measured in the natural state of the loofah);

[0029] 2) Dissolve aniline and ammonium persulfate in 1mol / L hydrochloric acid aqueous solution respectively to obtain 0.02mol / L aniline solution and 0.02mol / L ammonium persulfate solution;

[0030] 3) Add aniline solution to the container, soak the loofah in the aniline solution, then place the container in ice cubes at 0°C, add ammonium persulfate solution dropwise to the aniline solution, and the ammonium persulfate and aniline are equimolar , react at 0°C for 4 hours, at this time the color of the loofah turns green;

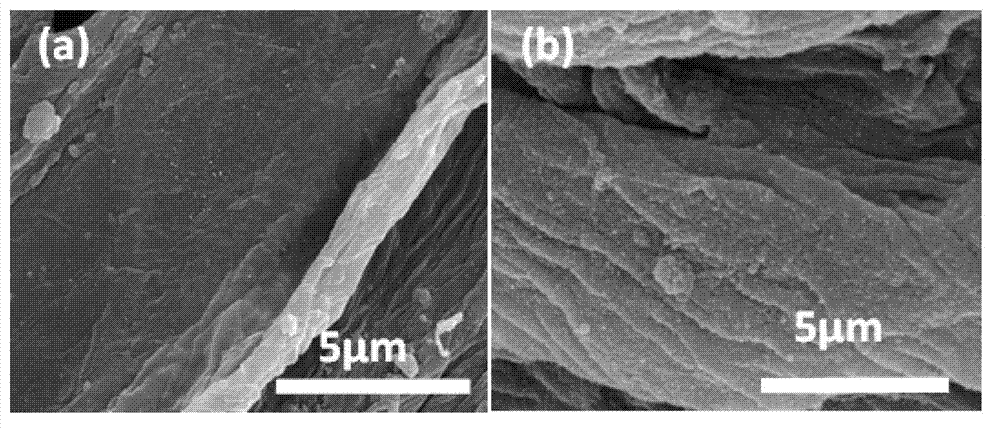

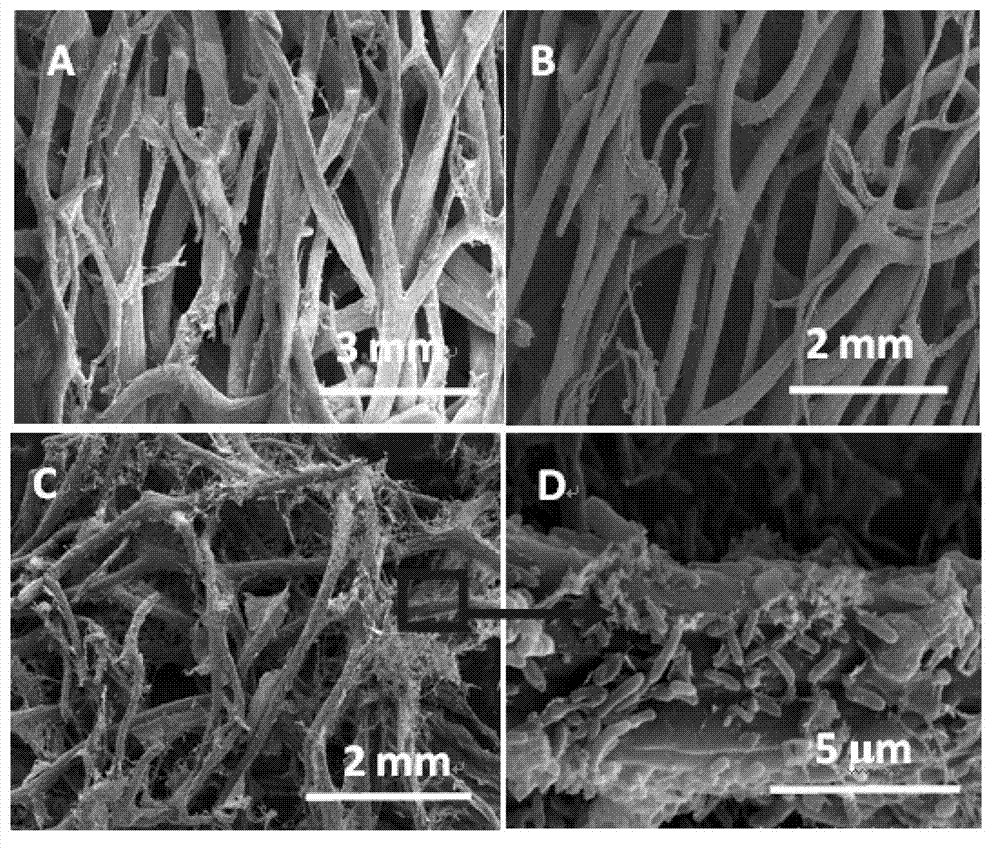

[0031] 4) Take out the loofah and dry it, put it into a cremation furnace, and carry out high-temperature anaerobic carbonization at a temperature of 900°C and a carbonization time of 30 minutes to obtain a three-d...

Embodiment 2

[0036] A preparation method of a three-dimensional porous electrode material, comprising the following steps:

[0037] 1) Take the loofah and cut it into 2.0cm×1.5 cm×0.5 cm (length×width×thickness, measured in the natural state of the loofah);

[0038] 2) Dissolve aniline and ammonium persulfate in 0.1mol / L hydrochloric acid aqueous solution respectively to obtain 0.03mol / L aniline solution and 0.03mol / L ammonium persulfate solution;

[0039] 3) Add aniline solution to the container, soak the loofah in the aniline solution, and add ammonium persulfate solution dropwise to the aniline solution at 2°C, and the molar ratio of aniline to ammonium persulfate is 1.5, and react 4.5 at 2°C h, the color of the loofah turns green at this time;

[0040] 4) Take out the loofah and dry it, put it into a cremation furnace, and perform high-temperature anaerobic carbonization at a temperature of 750°C and a carbonization time of 180 minutes to obtain a three-dimensional porous electrode ma...

Embodiment 3

[0042] A preparation method of a three-dimensional porous electrode material, comprising the following steps:

[0043] 1) Take the loofah and cut it into 2.0cm×1.5 cm×0.5 cm (length×width×thickness, measured in the natural state of the loofah);

[0044] 2) Dissolve aniline and ammonium persulfate in 0.5mol / L hydrochloric acid aqueous solution respectively to obtain 0.01mol / L aniline solution and 0.01mol / L ammonium persulfate solution;

[0045] 3) Add aniline solution to the container, soak the loofah in the aniline solution, and add ammonium persulfate solution dropwise to the aniline solution at 4°C, and the molar ratio of aniline to ammonium persulfate is 2, and react for 5 hours at 4°C , at this time the color of the loofah turns green;

[0046] 4) Take out the loofah and dry it, put it into a cremation furnace, and carry out high-temperature anaerobic carbonization at a temperature of 800°C and a carbonization time of 60 minutes to obtain a three-dimensional porous electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com