Coated lithium ion battery diaphragm

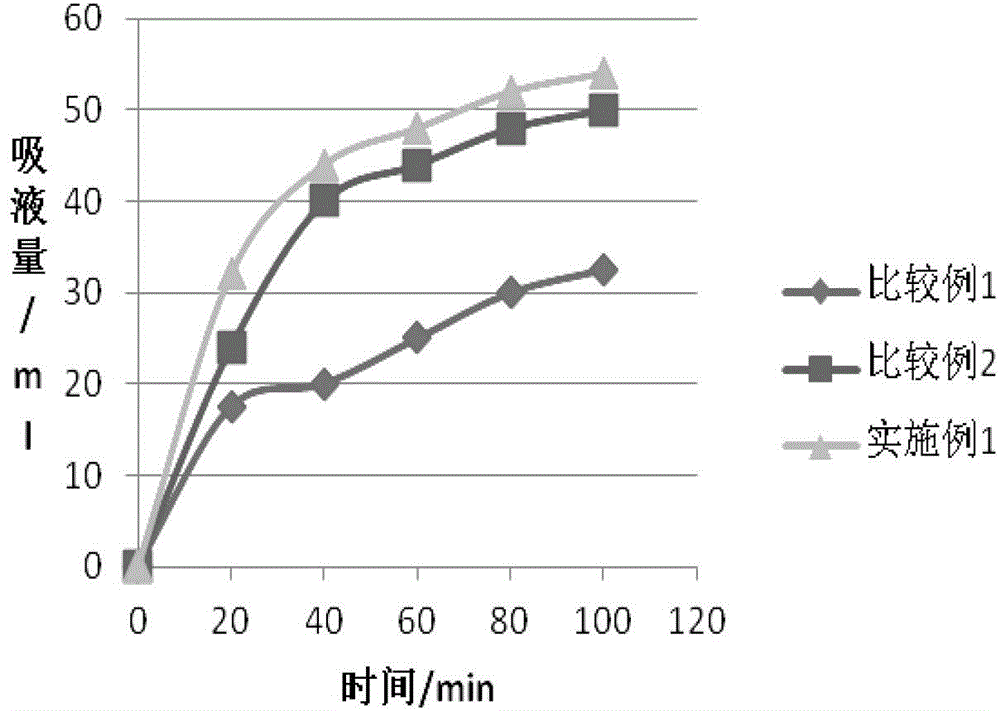

A technology for lithium-ion batteries and diaphragms, applied in the field of lithium-ion battery diaphragms and their preparation, can solve the problems of reduced porosity of diaphragms, lack of interaction, and reduced battery capacity, so as to avoid the reduction of micropores and coating peeling off , the effect of fast washing liquid speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation technology of coated lithium-ion battery diaphragm of the present invention comprises the following steps:

[0047] Step 1: basement membrane preparation, including the following steps:

[0048] 1) Add polyolefin, inorganic particles and plasticizer into the twin-screw extruder, and form a homogeneous phase by heating and shearing; the temperature during extrusion is preferably 150-250 degrees, and the screw speed is 100-600rpm.

[0049] 2) The mixture extruded by the twin-screw extruder passes through a coat hanger die to form a sheet, and is cooled on a cooling roll to form a thick film; the cooling roll can be used for single-side contact melt cooling or double-side contact melt cooling , the cooling roll temperature is preferably 0-50°C.

[0050] 3) By stretching in one direction or two directions, the stretching ratio is 9-50 times, and the thick film is stretched into a film; the stretching temperature is 80-130°C, preferably 90-125°C, and the str...

Embodiment 1

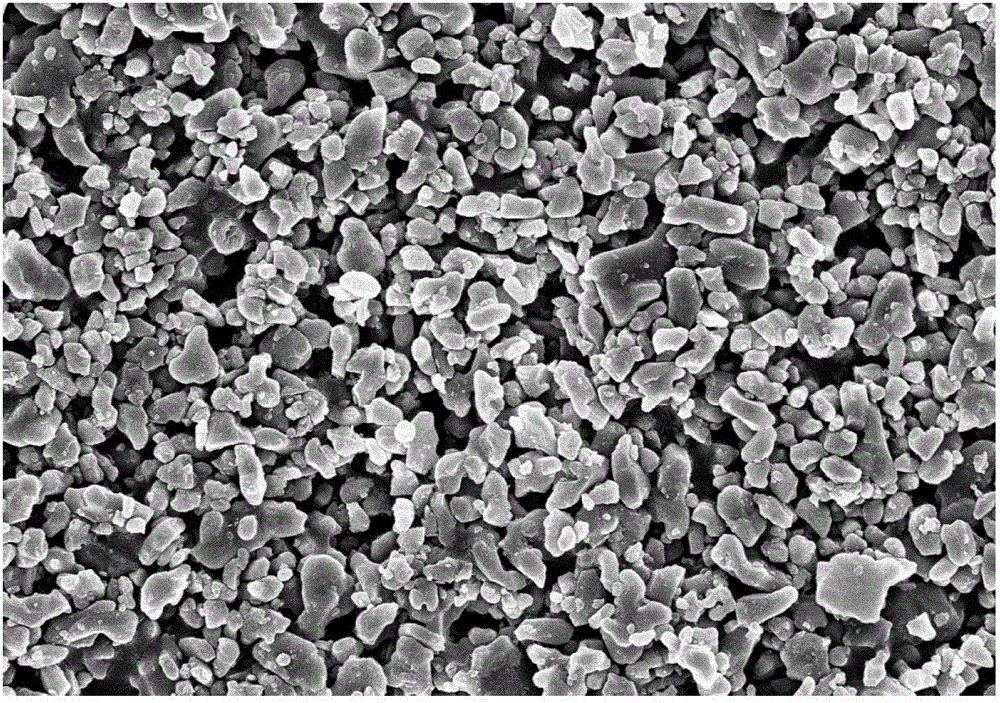

[0058] 1. Base film preparation: Extrude 20 parts of ultra-high molecular weight polyethylene with a molecular weight of 1 million, 10 parts of silicon dioxide with a particle size of 50 nm, and 70 parts of paraffin oil through a twin-screw extruder at a temperature of 220 ° C. The temperature of the cooling roll was 25° C., and a thick film with a thickness of 1000 μm was obtained. Enter the biaxial stretching machine to stretch 7 times in the longitudinal direction and transverse direction, and the stretching temperature is 120°C. The stretched film enters the heptane tank and stays for 10 minutes. After extraction, it enters the transverse stretching machine, stretches 1.2 times in the transverse direction and then retracts to 1.05 times, and the transverse stretching temperature is 130°C. Finally, after heat treatment, the heat treatment temperature is 130 ° C, and the treatment time is 5 minutes.

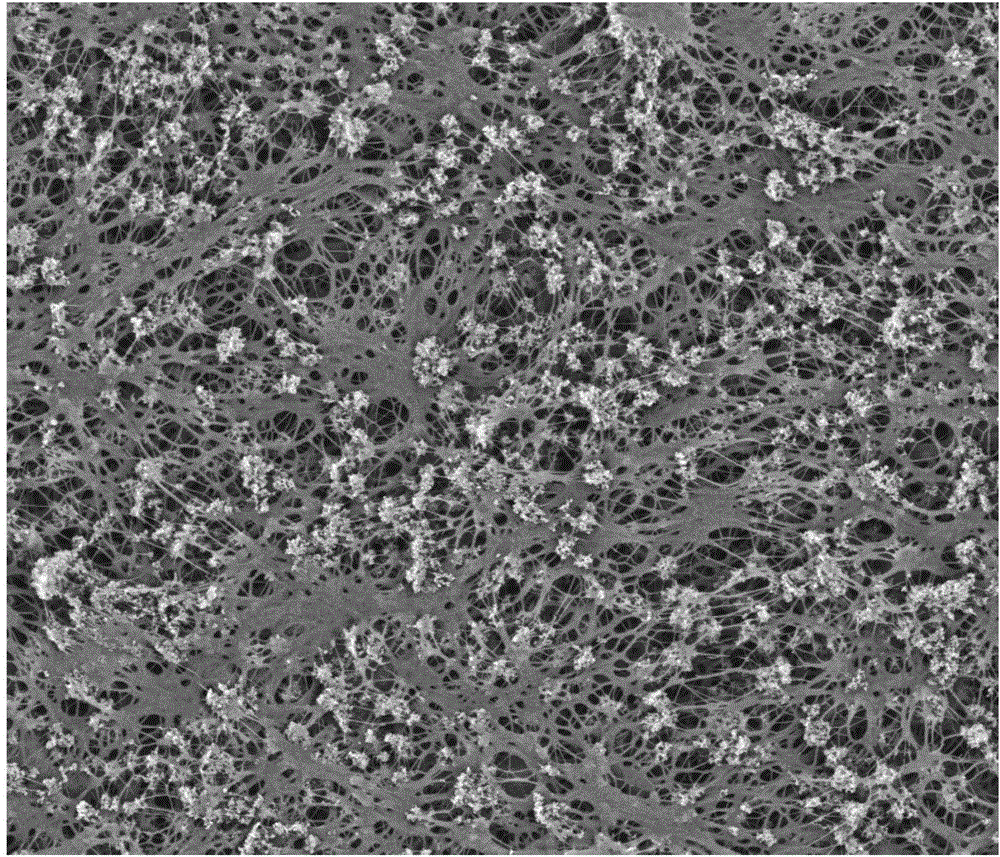

[0059] 2. Coating: Dissolve 10% PVDF-CTFE (polyvinylidene fluoride-chlor...

Embodiment 2

[0062] 1. Base film preparation: Extrude 15 parts of ultra-high molecular weight polyethylene with a molecular weight of 1 million, 15 parts of silicon dioxide with a particle size of 50 nm, and 70 parts of paraffin oil through a twin-screw extruder at a temperature of 220 ° C. The temperature of the cooling roll was 25° C., and a thick film with a thickness of 1000 μm was obtained. Enter the biaxial stretching machine to stretch 7 times in the longitudinal direction and transverse direction, and the stretching temperature is 120°C. The stretched film enters the heptane tank and stays for 10 minutes. After extraction, it enters the transverse stretching machine, stretches 1.2 times in the transverse direction and then retracts to 1.05 times, and the transverse stretching temperature is 130°C. Finally, after heat treatment, the heat treatment temperature is 130 ° C, and the treatment time is 5 minutes.

[0063] 2. Coating: Dissolve 10% PVDF-CTFE in acetone, stir and disperse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com