Puffed aquatic feed and preparation method thereof

A technology for aquatic feed and aquatic high-temperature-resistant enzymes, applied in animal feed, animal feed, applications, etc., can solve the problems of low feed utilization rate, polluted water environment, etc., and achieve the effect of improving digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: Preparation of extruded aquatic feed

[0049] Referring to accompanying drawing 1, the present invention provides a kind of preparation method of extruded aquatic feed, % by weight ratio w / w, concrete preparation method is as follows:

[0050] (1) 33% of the fermented dephenolized cottonseed meal, 24% of the fish meal, 7% of the soybean meal, 8% of the sunflower meal, and 19% of the flour raw materials are cleaned, coarsely crushed, and passed through a 40-60 mesh sieve Carry out a mixing, get the raw material rough mix stand-by.

[0051] (2) Superfinely pulverize the rough mixture of the above raw materials, pass through a 80-100 mesh sieve, and then mix with 0.5% multivitamins for fish, 2.0% mineral feed additives, 1.5% calcium dihydrogen phosphate, 2.0 % stone powder, 0.65% wheat bran, and 0.05% aquatic thermostable enzyme for secondary mixing.

[0052] (3) Evenly add 30% (w / w) water to the secondary mixture obtained in step (2) for tempering, then ...

Embodiment 2

[0057] Embodiment two: the preparation of extruded aquatic feed

[0058] Referring to accompanying drawing 1, the preparation of expanded aquatic feed is as follows:

[0059] (1) Raw material receiving and cleaning: Take 24 kg of fish meal, 33 kg of fermented dephenolized cottonseed meal, 7 kg of soybean meal, 8 kg of sunflower seed meal, and 19 kg of flour to remove impurities and clean up.

[0060] (2) Coarse crushing: raw materials are coarsely crushed and passed through a 40-60 mesh sieve.

[0061] (3) Ingredients mixing: Take the above raw materials and mix them once.

[0062] (4) Superfine pulverization: move the above-mentioned mixture into the superfine pulverization bin, carry out superfine pulverization, and pass through a 80-100 mesh sieve.

[0063] (5) Mixing of secondary ingredients: mix the above-mentioned superfine grinding mixture with 0.5 kg of multivitamins for fish, 2.0 kg of mineral feed additives, 1.5 kg of calcium dihydrogen phosphate, 2.0 kg of stone...

Embodiment 3

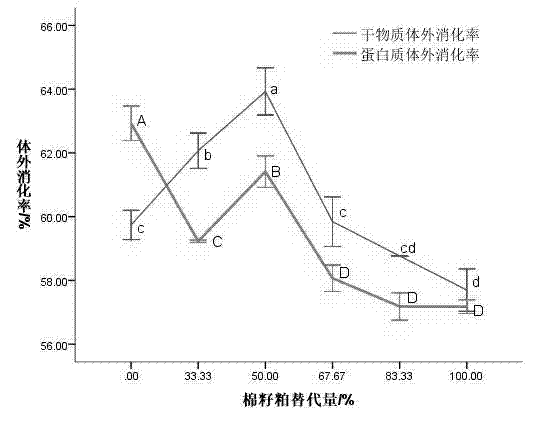

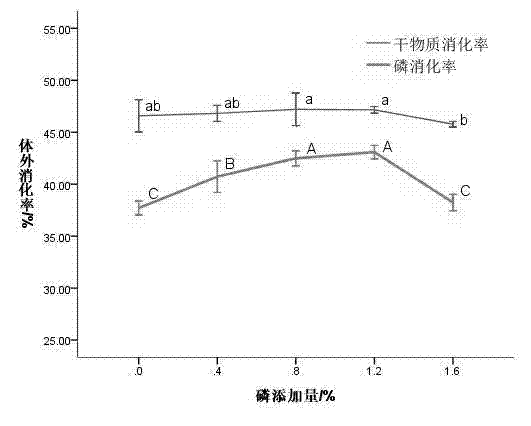

[0069] Embodiment 3: Determination of in vitro digestibility of extruded feed

[0070] The pepsin-trypsin two-step method is used to determine the in vitro digestibility of a substance in the feed, and make appropriate adjustments. Three parallel samples were made for each sample.

[0071] The test data were processed by SPSS 16.0 software commonly used in the field for one-way analysis of variance (ANOVA), and the Tukey multiple comparison method was used to analyze the significance of the difference in the mean (P<0.05). Values are expressed as mean ± standard deviation.

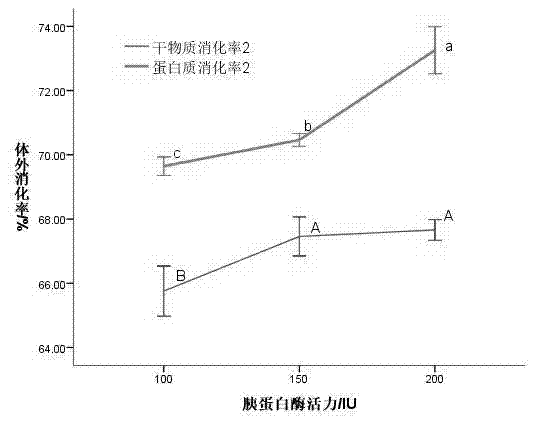

[0072] 1. Selection of optimal enzyme dosage for in vitro digestion test

[0073] 1.1. Selection of the most suitable amount of pepsin

[0074] Pepsin with different enzyme activity units (120IU, 180IU, 240IU) was selected, and the fermented dephenolized cottonseed meal was used as the substrate to carry out the digestion test. The results obtained are shown in Figure 2. According to the effects of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vitality | aaaaa | aaaaa |

| Vitality | aaaaa | aaaaa |

| Vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com