Extraction process and application of dephenolized cottonseed protein

The technology of dephenolized gossypol and extraction process is applied in the field of extraction process of dephenolized gossypol, and can solve the problems of low utilization rate of dephenolized gossypol, inability to effectively remove gossypol, and lower utilization rate of protein, so as to improve the dephenolization of gossypol. Phenol effect, reduction of free gossypol content, high apparent digestibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

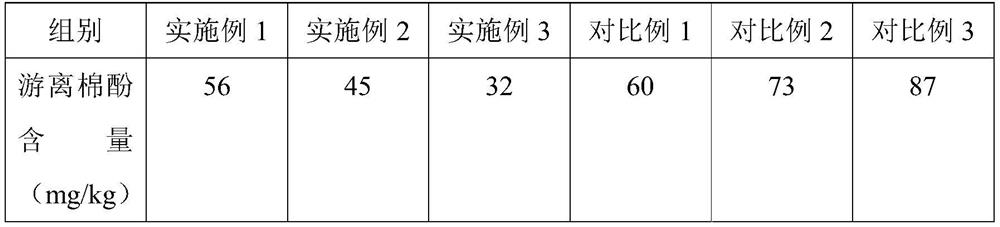

Examples

Embodiment 1

[0028] Embodiment 1, a kind of extraction process of dephenolized cottonseed protein

[0029] The extraction process of the dephenolized cottonseed protein comprises the following steps:

[0030] S1 Separate the shelled cottonseed from the shell and soften the cottonseed, control the softening water to 10%, soften the temperature at 42°C, squeeze the softened cottonseed, and control the output during the pressing process The temperature is 65°C, the residual oil rate of the cake embryo is controlled at 6%, and the crushed cake embryo is crushed. The diameter of the crushed cake is 3mm, and the crushed cake is dried. The temperature is 65°C, so that the moisture content of the cake reaches 3%, and the dried cake is obtained;

[0031] S2 Put the dry cake obtained in step S1 in a container, add petroleum ether, the amount of petroleum ether added is 3 times the mass of the dry cake, and extract the cake under ultrasonic conditions, the ultrasonic power is 30W, and the ultrasonic...

Embodiment 2

[0034] Embodiment 2, a kind of extraction process of dephenolized cottonseed protein

[0035] The extraction process of the dephenolized cottonseed protein comprises the following steps:

[0036] S1 Separate the shelled cottonseed from the shell and soften the cottonseed, control the softening water to 12%, soften the temperature at 50°C, squeeze the softened cottonseed, and control the output during the pressing process The temperature is 75°C, the residual oil rate of the cake embryo is controlled at 10%, and the crushed cake embryo is crushed. The diameter of the crushed cake is 8mm, and the crushed cake is dried. The temperature is 80°C, so that the moisture content of the cake reaches 5%, and the dried cake is obtained;

[0037] S2 Put the dry cake obtained in step S1 in a container, add petroleum ether, the amount of petroleum ether added is 7 times the mass of the dry cake, and extract the cake under ultrasonic conditions, the ultrasonic power is 50W, and the ultrasoni...

Embodiment 3

[0040] Embodiment 3, a kind of extraction process of dephenolized cottonseed protein

[0041] The extraction process of the dephenolized cottonseed protein comprises the following steps:

[0042] S1 Separate the shelled cottonseed from the shell and then soften the cottonseed, control the softening water to 11%, soften the temperature at 46°C, squeeze the softened cottonseed, and control the output during the pressing process The temperature is 68°C, the residual oil rate of the cake embryo is controlled at 7%, and the crushed cake embryo is crushed. The diameter of the crushed cake is 5mm, and the crushed cake is dried. The temperature is 75°C, so that the moisture content of the cake reaches 4%, and a dry cake is obtained;

[0043] S2 Put the dry cake obtained in step S1 in a container, add petroleum ether, the amount of petroleum ether added is 5 times the mass of the dry cake, and extract the cake under ultrasonic conditions, the ultrasonic power is 40W, and the ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com