Calcitriol soft capsules and preparation method thereof

A technology of calcitriol and soft capsules, which can be used in capsule delivery, bone diseases, pharmaceutical formulations, etc., and can solve problems such as poor stability, sensitivity to light and air, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

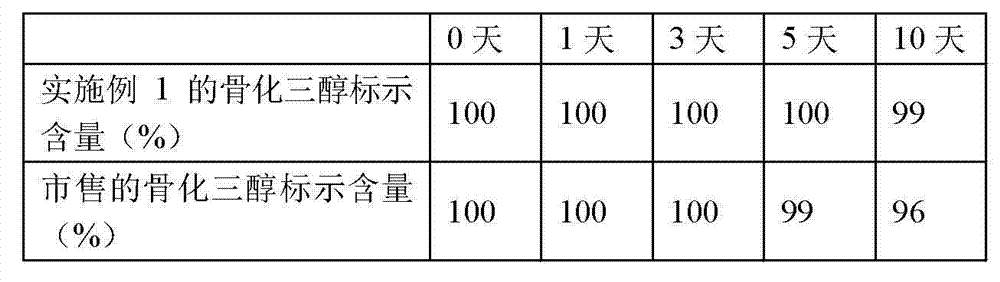

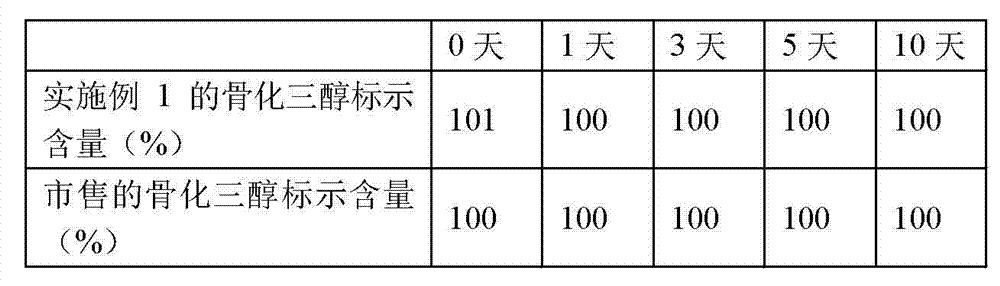

Examples

Embodiment 1

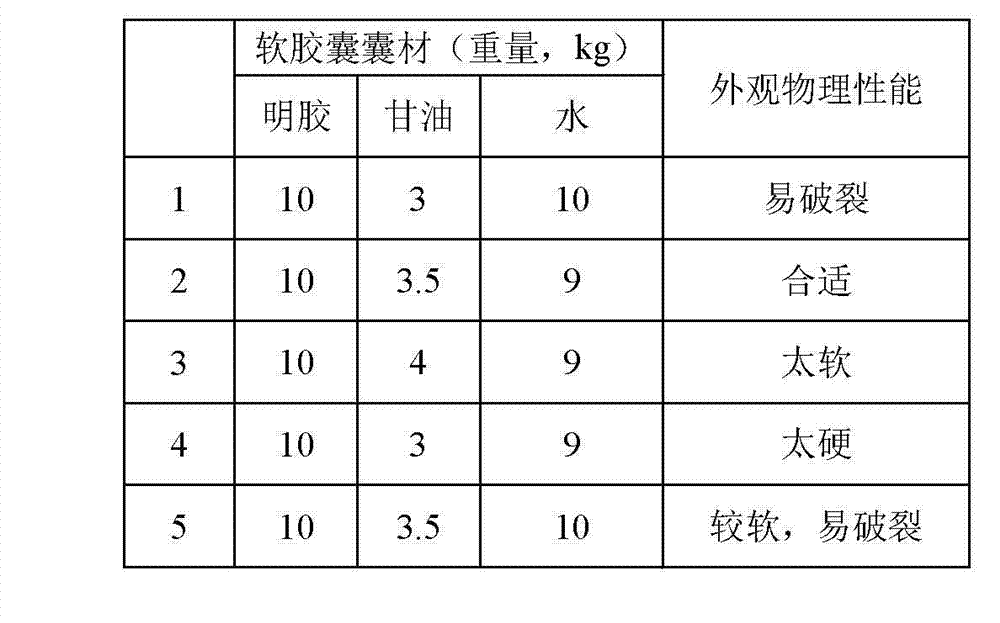

[0054] Preparation of soft capsule material:

[0055] Weigh 100 parts of gelatin in the prescribed quantity, put 3.5 parts of glycerin; swell in a mixed solution of 9 parts of water, heat until the gelatin dissolves, the heating temperature is 80°C, stir evenly and filter (70-80 mesh), vacuum defoaming: vacuum The temperature is -0.06~-0.1MPa, and the holding temperature is 60°C to obtain the soft capsule material.

[0056] Preparation of content solution:

[0057] Weigh 1 part of calcitriol, 30000 parts of isopropanol; 20000 parts of coconut oil and 80000 parts of polyoxyethylene hydrogenated castor oil (Cremophor-RH40), mix calcitriol, co-emulsifier, oil phase, Mix the emulsifier evenly, heat to 50°C for 30 minutes, stir, evacuate to remove all air bubbles, dissolve the drug until a uniform and clear solution is obtained, and then put it into a barrel for later use.

[0058] Compress it into soft capsules with a rotary molding machine, and dry them with cold air in a tumbl...

Embodiment 2

[0060] Take 100 parts of gelatin by weight, put 3.5 parts of glycerin; 9 parts of water, prepare the soft capsule material according to the method of Example 1, then weigh 2 parts of calcitriol, 33000 parts of polyethylene glycol 400; palmitic acid 25,000 parts of isopropyl ester, 90,000 parts of polyoxyethylene (20) sorbitan oleate (Tween80), prepared content solution according to the method of Example 1, and then prepared soft capsule according to the method of Example 1.

Embodiment 3

[0062] Take 100 parts of gelatin by weight, put 3.5 parts of glycerin; 9 parts of water, prepare soft capsule material according to the method of Example 1, then weigh 2 parts of calcitriol, 400 parts of propylene glycol; 35000 parts of propylene glycol; isopropyl myristate 24,000 parts of ester, 100,000 parts of polyoxyethylene castor oil (Cremophor-EL-80), the content solution was prepared according to the method of Example 1, and then soft capsules were prepared according to the method of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com