A kind of antibacterial polystyrene modified material and preparation method thereof

A polystyrene, modified material technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve difficult problems, ensure effective utilization, prevent crystal nucleation, and enhance toughness and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

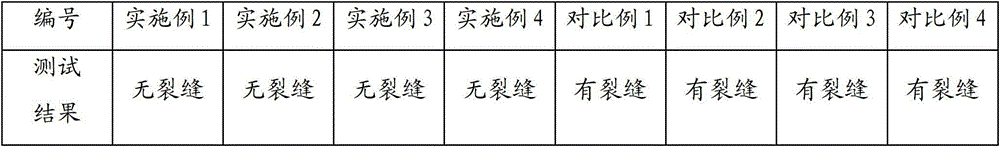

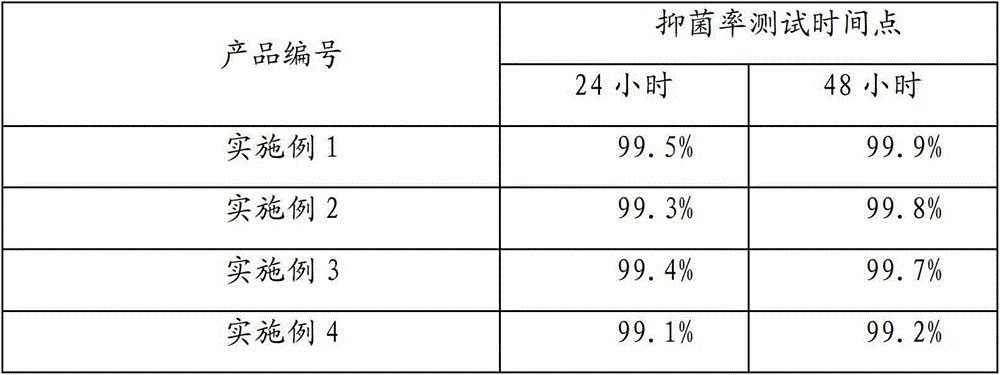

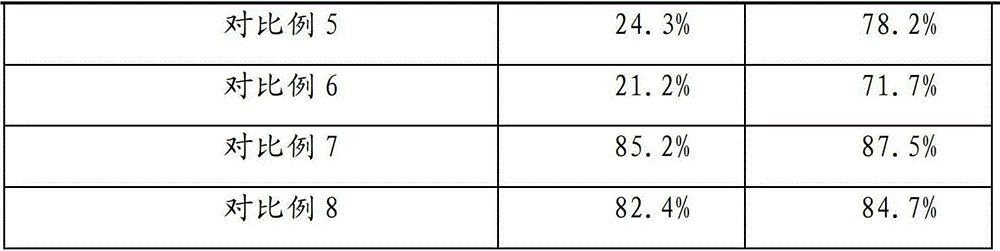

Examples

Embodiment 1

[0027] Using high-speed pre-mixing and dispersing one-time extrusion process, 76 parts of polystyrene, 1 part of nano-titanium dioxide particles, 2 parts of nano-silver particles, 6 parts of ethylene-propylene rubber as a dispersion modifier, and two parts of styrene-butyl acrylate 10 parts of graft-modified ethylene-propylene rubber, 5 parts of nano-apatite whiskers, 0.01 parts of antioxidant, and 5 parts of processing aids are dispersed and mixed by a high-speed mixer; melted, mixed and extruded by a twin-screw extruder Take out, cool, dry and cut into pellets.

[0028] The above-mentioned granules are injection-molded into plates by an injection molding machine, placed overnight under natural conditions, and then the plates are placed in an oxygen-containing gas atmosphere, and pure titanium is used as a target material, and the plasma sputtering process is performed using an existing plasma coating machine , in the plasma sputtering process, the radio frequency power is 30...

Embodiment 2

[0031] The high-speed premixing and dispersing extrusion process of Example 1 is used to granulate. The parts by weight of each component are: 80 parts of polystyrene, 0.5 part of nano-titanium dioxide particles, 1 part of nano-silver particles, and 3 parts of α-olefin oligomers. 6 parts, 6 parts of styrene-butyl acrylate binary graft modified ethylene-propylene rubber, 3 parts of nano-apatite whiskers, 0.1 part of antioxidant, and 0.1 part of processing aid.

[0032] The above-mentioned pellets are blown into containers by a blow molding machine, placed overnight under natural conditions, and then the container is placed in an oxygen-containing gas atmosphere, pure titanium is used as a target, and plasma sputtering is performed using an existing plasma coating machine In the plasma sputtering process, the radio frequency power is 50w, the bias voltage is 60V, and the sputtering time is 4 minutes.

[0033] After sputtering, the thickness of the titanium dioxide film on the su...

Embodiment 3

[0035]The high-speed premixing and dispersing primary extrusion process of Example 1 is used to granulate, and the parts by weight of each component are: 83 parts of polystyrene, 0.8 part of nano-titanium dioxide particles, 1.5 parts of nano-silver particles, and 5 parts of α-olefin oligomers. 8 parts, 8 parts of styrene-butyl acrylate binary graft modified ethylene-propylene rubber, 5 parts of nano-apatite whiskers, 1 part of antioxidant, and 3 parts of processing aid.

[0036] The above-mentioned pellets are injection-molded into pipes by injection molding machine, placed overnight under natural conditions, and then the pipes are placed in an oxygen-containing gas atmosphere, pure titanium is used as the target material, and the plasma sputtering process is performed using an existing plasma coating machine , in the plasma sputtering process, the radio frequency power is 100w, the bias voltage is 80V, and the sputtering time is 8 minutes.

[0037] After sputtering, the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com