Preparation method of titanium dioxide coated nano-copper with core-shell structure

A technology of titanium dioxide and core-shell structure is applied in the field of photocatalytic nanomaterials, which can solve the problems of easy recombination of photogenerated holes, low utilization rate of sunlight, and influence on the process of industrialization of heterogeneous photocatalytic reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

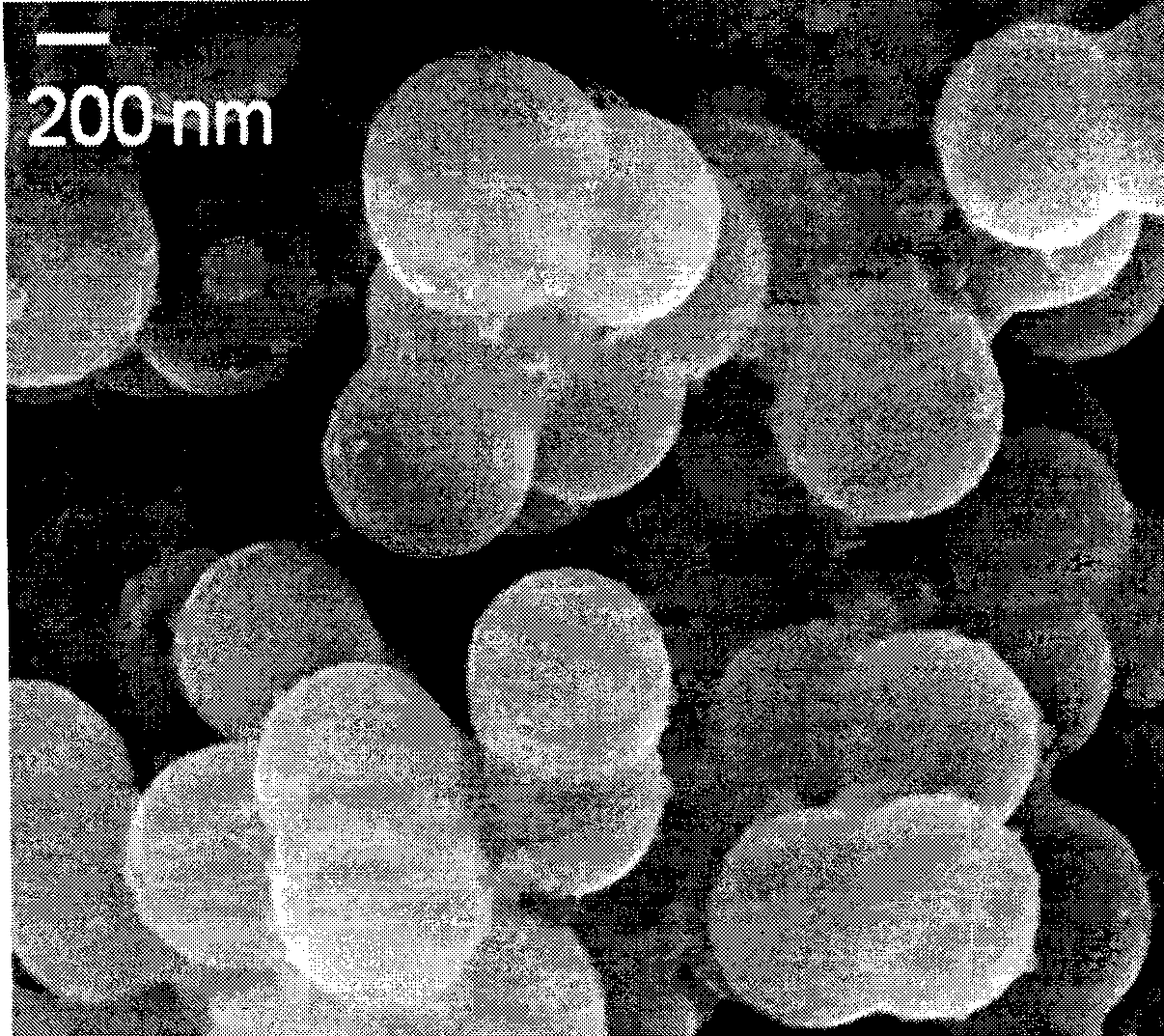

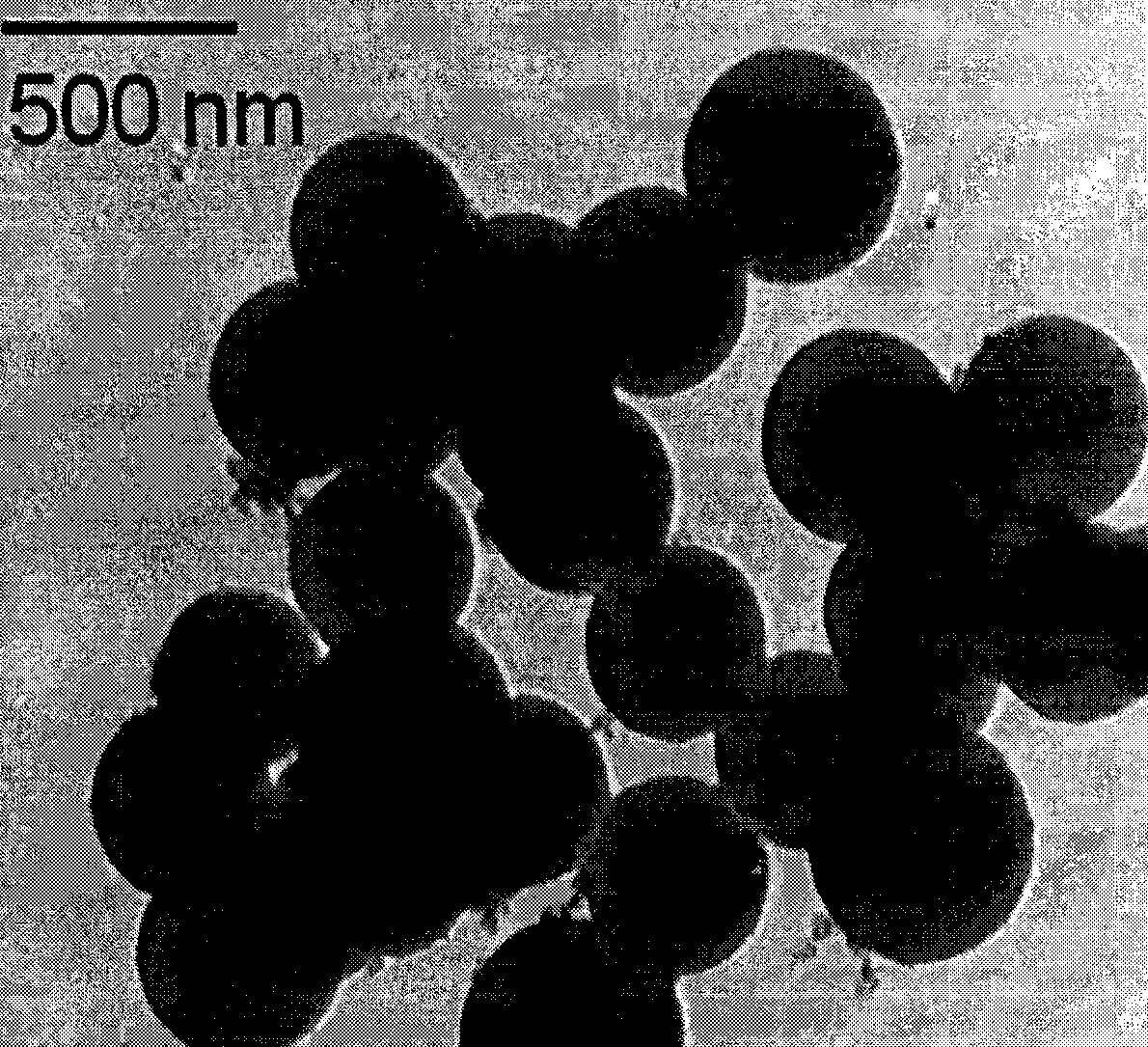

Image

Examples

Embodiment 1

[0019] Preparation of copper nanoparticles:

[0020] Take 100ml 0.04M CuSO 4 Add the aqueous solution to the same volume of 0.13M NaBH 4 In the solution, the mixed solution was mixed at room temperature for 1 minute, and the obtained precipitate was centrifuged at 11,500 rpm for 10 minutes, and then washed with distilled water and absolute ethanol for 3 times respectively, and the washed product was dried in a vacuum oven at a temperature of 30°C 12h;

[0021] Titanium dioxide coated nano-copper:

[0022] Dissolve 0.016 g of the prepared nano-copper particles in 50 ml of absolute ethanol solution, and ultrasonicate for 5 minutes to obtain a mixed solution;

[0023] Dissolve 0.74ml of isopropoxytitanium solution in 50ml of absolute ethanol solution, add dropwise to the mixed solution of nano-copper in absolute ethanol under stirring, continue to stir, and react for 1 hour to obtain the mixed solution;

[0024] Add the solution with a volume ratio of 0.09 (water / absolute eth...

Embodiment 2

[0027] Preparation of copper nanoparticles:

[0028] Take 50ml 0.4M L-ascorbic acid solution and add dropwise to 50ml 10mM CuCl 2 2H 2 In the O solution, keep the temperature at 80°C in an oil bath, continue to stir and react for 16 hours, centrifuge the obtained precipitate at 11500rpm for 10 minutes, then wash with distilled water and absolute ethanol for 3 times respectively, and put the washed product in Dry in a vacuum oven at 30°C for 12 hours;

[0029] Titanium dioxide coated nano-copper:

[0030] Take 0.0176 g of the prepared nano-copper particles and dissolve them in 50 ml of absolute ethanol solution, and ultrasonicate for 5 minutes to obtain a mixed solution;

[0031] Dissolve 1.5ml of isopropoxytitanium solution in 50ml of absolute ethanol solution, and add dropwise to the mixed solution of nano-copper in absolute ethanol under stirring. After the addition is completed, continue to stir and react for 2 hours to obtain mixed solution;

[0032] Add the solution ...

Embodiment 3

[0035] Preparation of copper nanoparticles:

[0036] Under stirring, add the hydrazine solution dropwise to 45ml of 0.43mM copper chloride solution (the molar ratio of hydrazine to copper chloride solution is 20), the reaction temperature is maintained at 35°C, when the color of the solution changes from blue to When it is yellow, there are nano-copper particles. Centrifuge the obtained precipitate at 11,500 rpm for 10 minutes, then wash with distilled water and absolute ethanol for 3 times respectively, and dry the washed product in a vacuum drying oven at a temperature of 50°C for 4 hours;

[0037] Titanium dioxide coated nano-copper:

[0038] Dissolve 0.0224 g of the prepared nano-copper particles in 50 ml of absolute ethanol solution, and ultrasonicate for 5 minutes to obtain a mixed solution;

[0039] Dissolve 3.0ml of isopropoxytitanium solution in 50ml of absolute ethanol solution, and add it dropwise to the mixed solution of nano-copper in absolute ethanol under stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com