Method for directly producing low-molecular weight heparin sodium through heparin sodium crude product

A low-molecular-weight, heparin sodium technology, applied in the field of preparation of low-molecular-weight heparin sodium, can solve problems such as increased raw material costs, achieve the effects of increased yield, improved safety, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

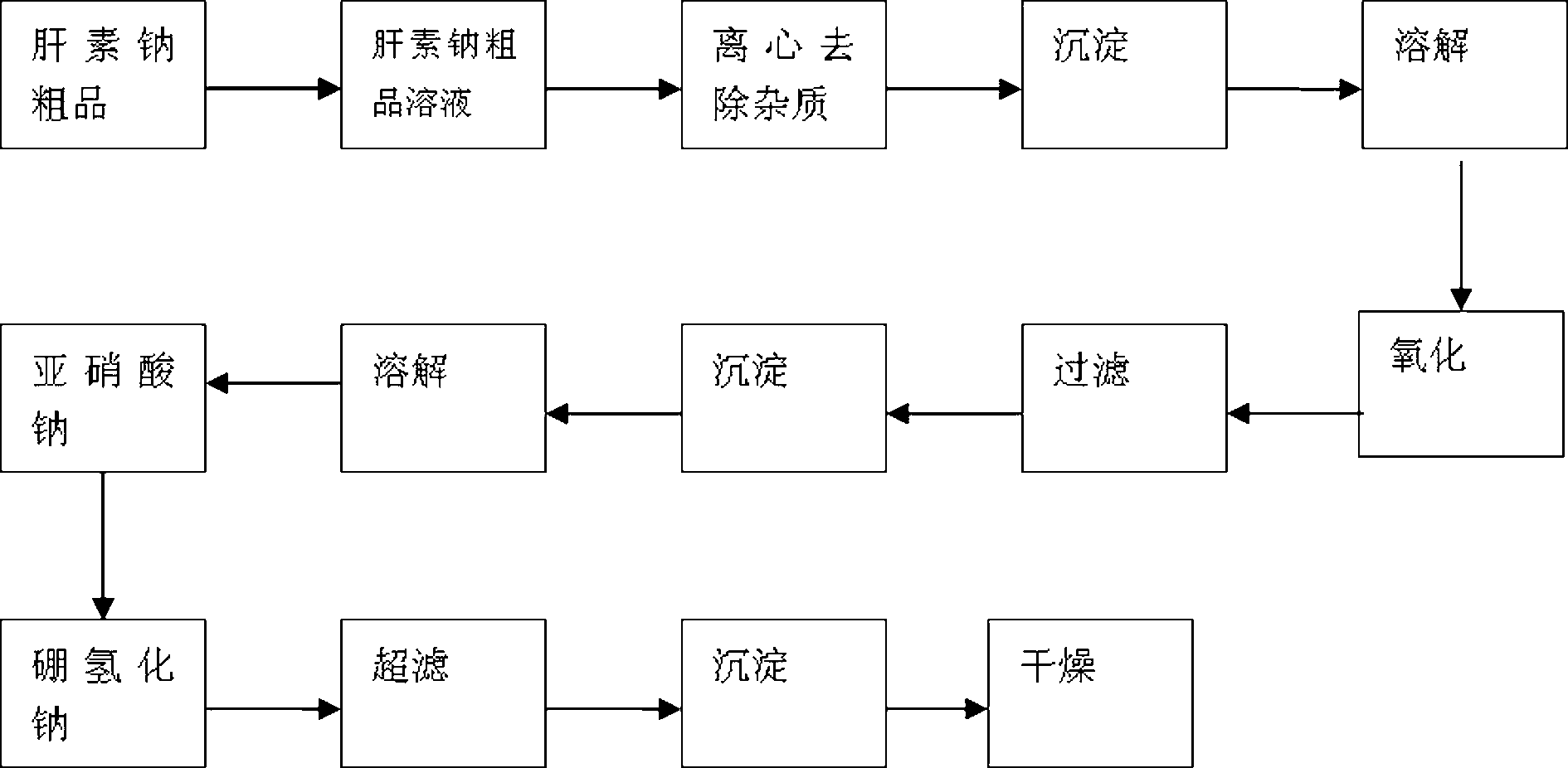

[0021] A method for directly producing low-molecular-weight heparin sodium from crude heparin sodium, such as figure 1 shown, including the following steps:

[0022] (1) Dissolve the crude heparin sodium with 4wt% sodium chloride solution into a 10wt% crude heparin solution; use 6mol / L hydrochloric acid or 40wt% sodium hydroxide solution to adjust the pH of the crude heparin solution 8.5.

[0023] (2) Centrifuge with a high-speed centrifuge to remove insoluble matter. The liquid obtained by centrifugation was precipitated with ethanol 0.5 times the volume of the solution, and the temperature of the precipitated liquid was kept below 10° C., and stood still for 12 hours, and the precipitate A was collected.

[0024] (3) Dilute the precipitate A with purified water to make a 10wt% heparin sodium solution. After it is completely dissolved, add hydrogen peroxide with a volume of 1.0v / v% of the solution to oxidize for 12 hours, and adjust the pH to 10.5 at the same time. Filter ...

Embodiment 2

[0029] A method for directly producing low-molecular-weight heparin sodium from crude heparin sodium, such as figure 1 shown, including the following steps:

[0030] (1) Dissolve the crude heparin sodium with 2wt% sodium chloride solution into a 5wt% crude heparin sodium solution; use 6mol / L hydrochloric acid or 40wt% sodium hydroxide solution to adjust the pH of the crude heparin sodium solution 6.5.

[0031] (2) Centrifuge with a high-speed centrifuge to remove insoluble matter. The liquid obtained by centrifugation was precipitated with ethanol of 1 times the volume of the solution, and the temperature of the precipitated liquid was kept below 10°C, and stood still for 6 hours, and the precipitate A was collected.

[0032] (3) Dilute the precipitate A with purified water to make a 5wt% heparin sodium solution. After it is completely dissolved, add 0.5% hydrogen peroxide to oxidize for 24 hours, filter with filter paper, add 2.0 times the volume of the solution to precipit...

Embodiment 3

[0037] A method for directly producing low-molecular-weight heparin sodium from crude heparin sodium, such as figure 1 shown, including the following steps:

[0038] (1) Dissolve the crude heparin sodium with 3wt% sodium chloride solution into a 15wt% crude heparin sodium solution; use 6mol / L hydrochloric acid or 40wt% sodium hydroxide solution to adjust the pH of the crude heparin sodium solution 7.5.

[0039] (2) Centrifuge with a high-speed centrifuge to remove insoluble matter. The liquid obtained by centrifugation was precipitated with ethanol 0.8 times the volume of the solution, the temperature of the precipitated liquid was kept below 10°C, and the precipitate A was collected for 16 hours.

[0040] (3) Dilute the precipitate A with purified water to make a 15wt% heparin sodium solution. After it is completely dissolved, add 1.5% hydrogen peroxide to oxidize for 24 hours, filter with filter paper, add 2.0 times the volume of the solution to precipitate with ethanol, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com