Collagen-coated micro-carrier used in animal cell culture, and preparation method thereof

A collagen and microcarrier technology, applied in animal cells, biochemical equipment and methods, tissue culture, etc., can solve the problems of biocompatibility, unsatisfactory cell culture effect, weak protein connection, etc., and achieve optimal cell culture Effect, coating amount reduction, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

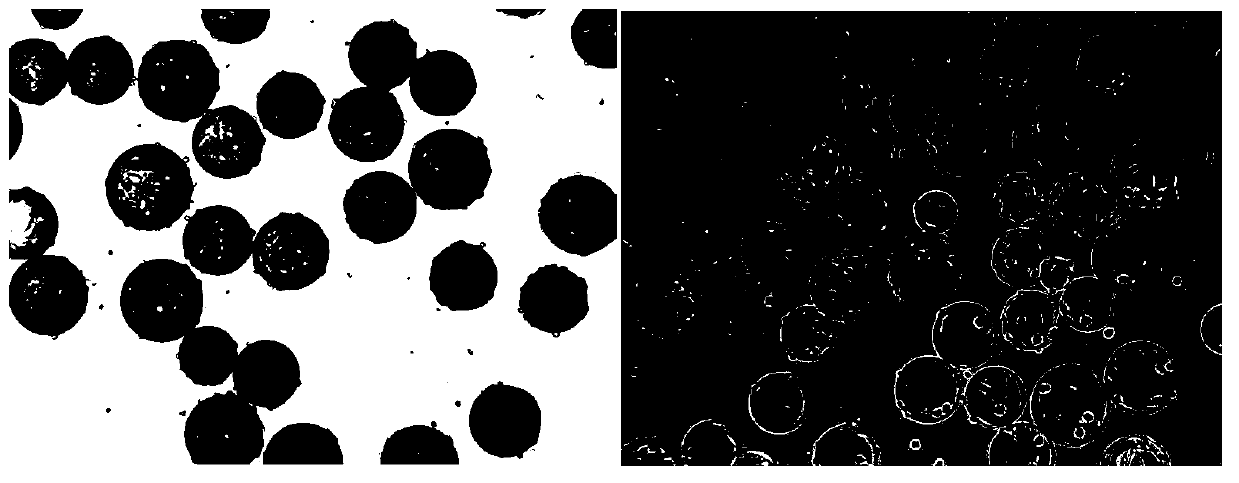

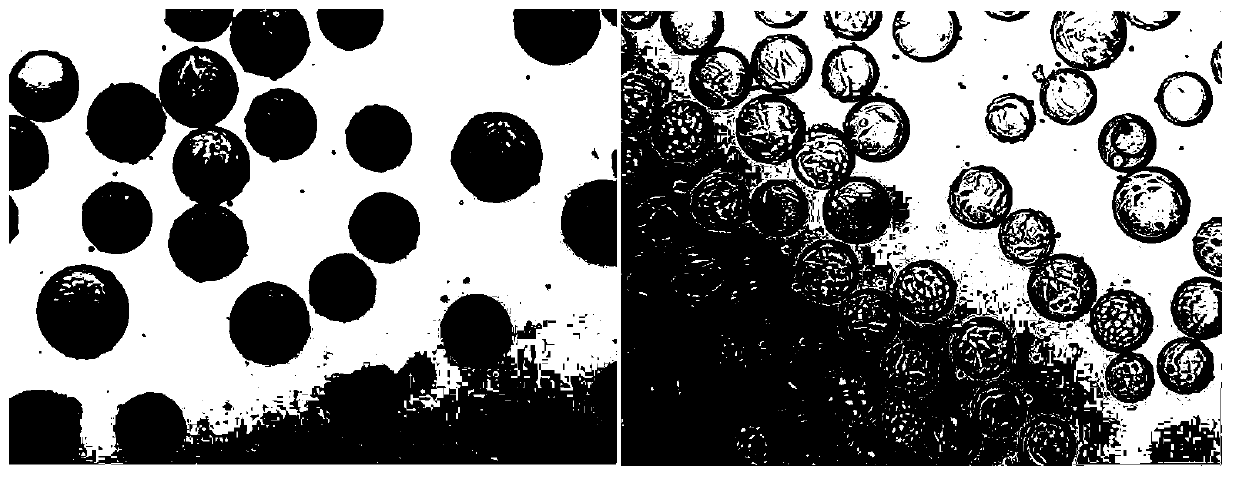

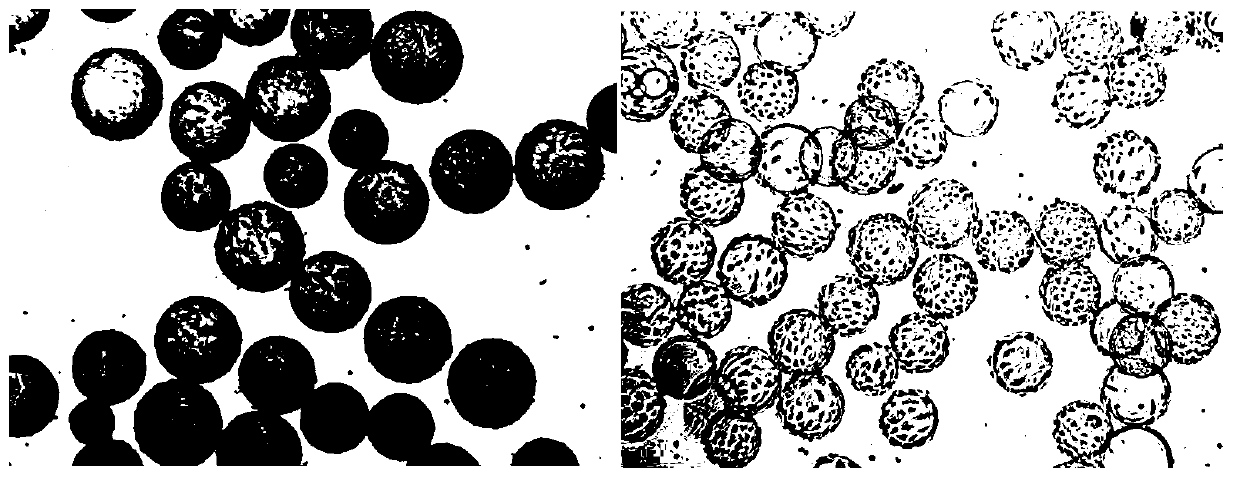

Image

Examples

Embodiment 1

[0063] The preparation of embodiment 1 collagen coating microcarrier

[0064] Select konjac glucomannan microspheres with a particle size of 50 μm-100 μm, wash and dry them with a sand core funnel, weigh 20 g, put them in a three-necked flask, add 20 mmol of activating reagent 1,4-butanediol diglycidyl ether, and hydroborate Sodium 40mg, 0.1M NaOH solution 40mL, react at 300rpm at 25°C for 18h. After the reaction, the microspheres were washed and dried, and 10 mL of NaHCO with pH=8 was added 3 -Na 2 CO 3 5 g of fish gelatin with an average molecular weight of 5,000 was added to the buffer, and reacted at 200 rpm at 15°C for 24 hours to couple the protein. Then, after mixing the reacted system, add 100mL of water at 10°C, and rinse twice with PBS with pH=7. Put the treated microspheres into the flask, then add 20mmol of cross-linking reagent malondialdehyde and 40mL of PBS buffer, stir and react at 65°C for 0.5h, clean the microspheres with a sand core funnel after the reac...

Embodiment 2

[0065] The preparation of embodiment 2 collagen coating microcarriers

[0066] Select konjac glucomannan microspheres with a particle size of 100 μm-160 μm, wash and extract 20 g with a sand core funnel, place it in a three-necked flask, add 0.1 moL of activating reagent diepoxidized butadiene, 1 g of sodium borohydride, and 100 mL of 0.5M NaOH solution, React at 50 rpm at 65 °C for 0.5 h. After the reaction, the microspheres were washed and dried, and 80 mL of NaHCO with pH=10 was added 3 -Na 2 CO 3Add 5 g of bovine gelatin with an average molecular weight of 5,000 to the buffer solution, react at 300 rpm at 40° C. for 5 h, and couple the protein. Then, after mixing the reacted system, add 500 mL of deionized water at 5°C, and rinse twice with PBS with pH=7.2. The treated microspheres were put into the flask, then added the cross-linking reagent glutaraldehyde 0.2mol and PBS buffer 100mL, stirred and reacted at 15°C for 24h, cleaned the microspheres with a sand core funne...

Embodiment 3

[0067] The preparation of embodiment 3 collagen coated microcarriers

[0068] Select konjac glucomannan microspheres with a particle size of 160 μm-250 μm, wash and extract 20 g with a sand core funnel, put it in a three-necked flask, add 0.2 mol of activating reagent n-butyl glycidyl ether, 10 mg of sodium borohydride, and 20 mL of 1.5M KOH solution , reacted at 150rpm at 25°C for 16h. After the reaction, wash and dry the microspheres, add 100mL NaHCO with pH=12 3 -Na 2 CO 3 Add 1 g of porcine gelatin with an average molecular weight of 10,000 to the buffer solution, react at 50 rpm at 65° C. for 0.5 h, and couple the protein. Then the reacted system was mixed evenly, added dropwise into 1 L of deionized water at 0°C, and rinsed twice with PBS of pH=7.4. The treated microspheres were added to the flask, and then 50 mmol of cross-linking reagent succinaldehyde and 150 mL of PBS buffer were added, and the reaction was stirred at 50°C for 5 h. After the reaction, the microsp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com