Multi-vibroflot resonance ground treatment equipment and method

A technology of foundation treatment and vibrator, which is applied in the direction of infrastructure engineering, soil protection, construction, etc., can solve the problems of unsuitable deep foundation reinforcement, low bearing capacity, loose wind-blown sand on the upper part, etc., and achieve the elimination of uneven foundation performance, improve the bearing capacity of the foundation, and reduce the vibration amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

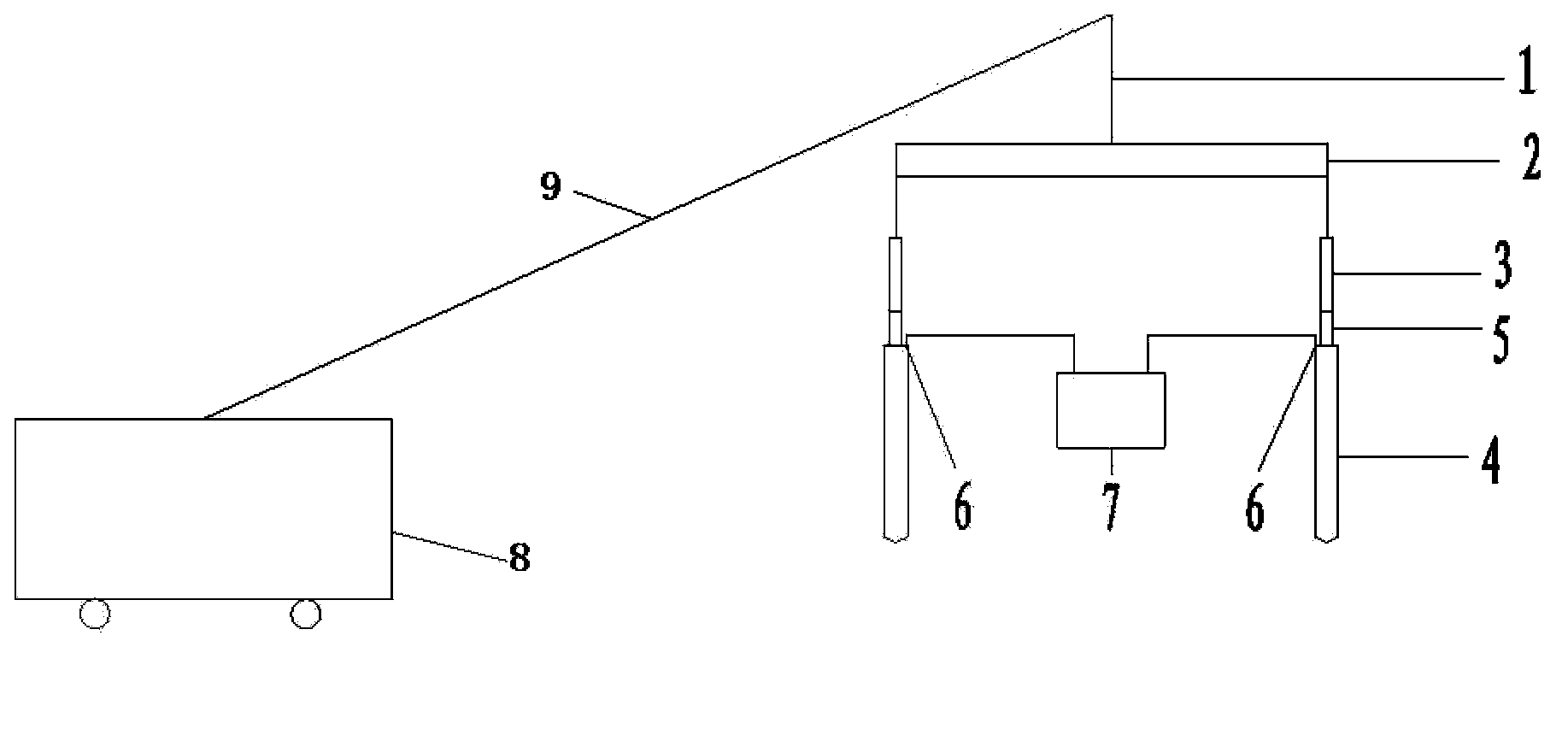

[0032] Such as figure 1 As shown, the vibration impactor resonance foundation treatment equipment with several heads in this embodiment includes a main body 8, a cantilever 9, a sling assembly 1, a channel steel 2, at least two steel cables 3 and a number of vibrating devices 4 corresponding to the steel cables 3 , the equipment main body 8 is connected to the sling assembly 1 through the cantilever 9, the sling assembly 1 is fixedly connected to the middle position of the channel steel 2, the two sides of the channel steel 2 are connected to at least two evenly arranged steel cables 3, and the steel cables 3 The bottom is fixedly connected with the corresponding vibrating device 4. The vibrating device 4 is a vibrator with a deflection rotor driven by a motor inside. The vibrating device 4 is provided with a water inlet 6, and the water inlet 6 is connected to the high-pressure water pump. 7 connection, each vibration device 4 and the steel cable 3 are provided with buffer an...

Embodiment 2

[0037] A sandy soil foundation with a thickness of 10-12 meters, a clay content of 7.5%, and a permeability coefficient of 10 -3 cm / s.

[0038] Design requirements: The bearing capacity of the 12-meter sandy soil foundation reaches 100KPa.

[0039] Step 1: measure the compacted depth of the sand layer: according to the conventional method, measure the compacted depth of the sand layer on the constructed sandy soil foundation, and the compacted depth of the sand layer is 3 meters;

[0040] Step 2: Vibration construction: use the vibro impactor resonance foundation treatment equipment described in Example 1, the bottom of the channel steel is connected to the corresponding vibrating device through two steel cables, and the distance between two adjacent vibrating devices is 2 meters , each vibrating device is connected with a high-pressure water pump, and several locations to be constructed are selected on the sandy soil foundation to be constructed. are the same, and for any l...

Embodiment 3

[0050] A sandy soil foundation with a thickness of 18-25 meters, a clay content of 8.5%, and a permeability coefficient of 2×10 -3 cm / s.

[0051] Design requirements: The bearing capacity of the 18-meter sandy soil foundation reaches 120KPa.

[0052] Step 1: measure the compacted depth of the sand layer: according to the conventional method, measure the compacted depth of the sand layer on the constructed sandy soil foundation, and the compacted depth of the sand layer is 15 meters;

[0053] Step 2: Vibration construction: use the vibro impactor resonance foundation treatment equipment described in Example 1, the bottom of the channel steel is connected to the corresponding vibrating device through three steel cables, the three vibrating devices are distributed in a triangle, and the three vibrating devices The distance between the devices is 5 meters, and each vibrating device is connected with a high-pressure water pump. On the sandy soil foundation to be constructed, sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com