Laminated composite heat preservation board and preparation method thereof

A composite thermal insulation and core sandwich technology, applied in thermal insulation, chemical instruments and methods, building components, etc., can solve the problems of difficult construction, limited resources, large deformation coefficient, etc., achieve excellent thermal insulation performance, and the process is simple and easy to operate. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

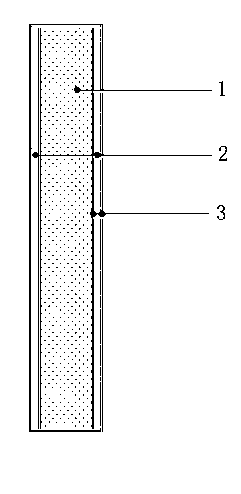

[0033] combine figure 1 , the present invention provides a sandwich composite thermal insulation board consisting of two composite fiber boards with composite fiber cotton sandwiched between them; The upper and lower sides of the upper and lower sides are laminated with aluminum foil paper 3.

[0034] Tin foil can also be used instead of aluminum foil 3.

[0035] The upper surface of the sandwich composite insulation board is evenly distributed with needle-punched small holes, and its hole density is 1.0 holes / cm 2 .

[0036] The composite fiber cotton is formed by laminating two or more layers of fiber webs 1, and the surface of the fiber contains a flame retardant, and the flame retardant is a phosphorus nitrogen type flame retardant.

[0037] The thickness of the aluminum foil paper is 0.8mm.

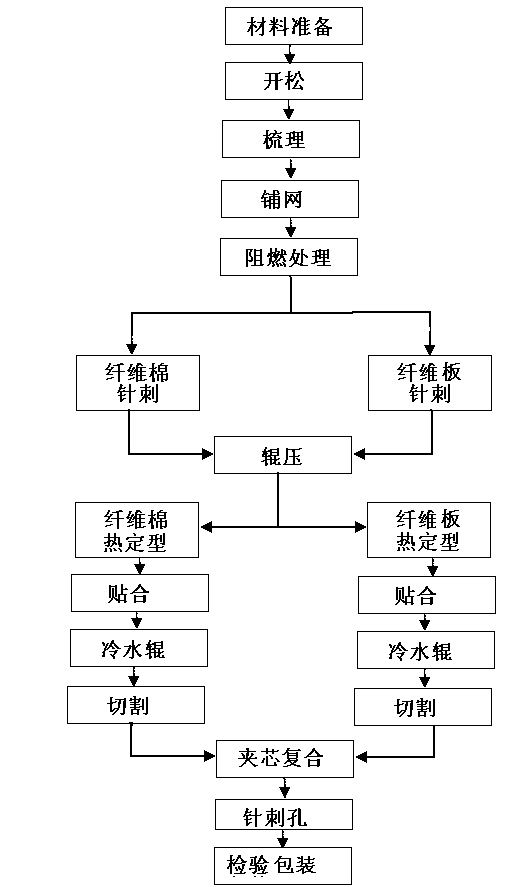

[0038] combine figure 2 , the specific preparation process of the sandwich composite insulation board of the present invention comprises the following steps:

[0039] Material...

Embodiment 2-4

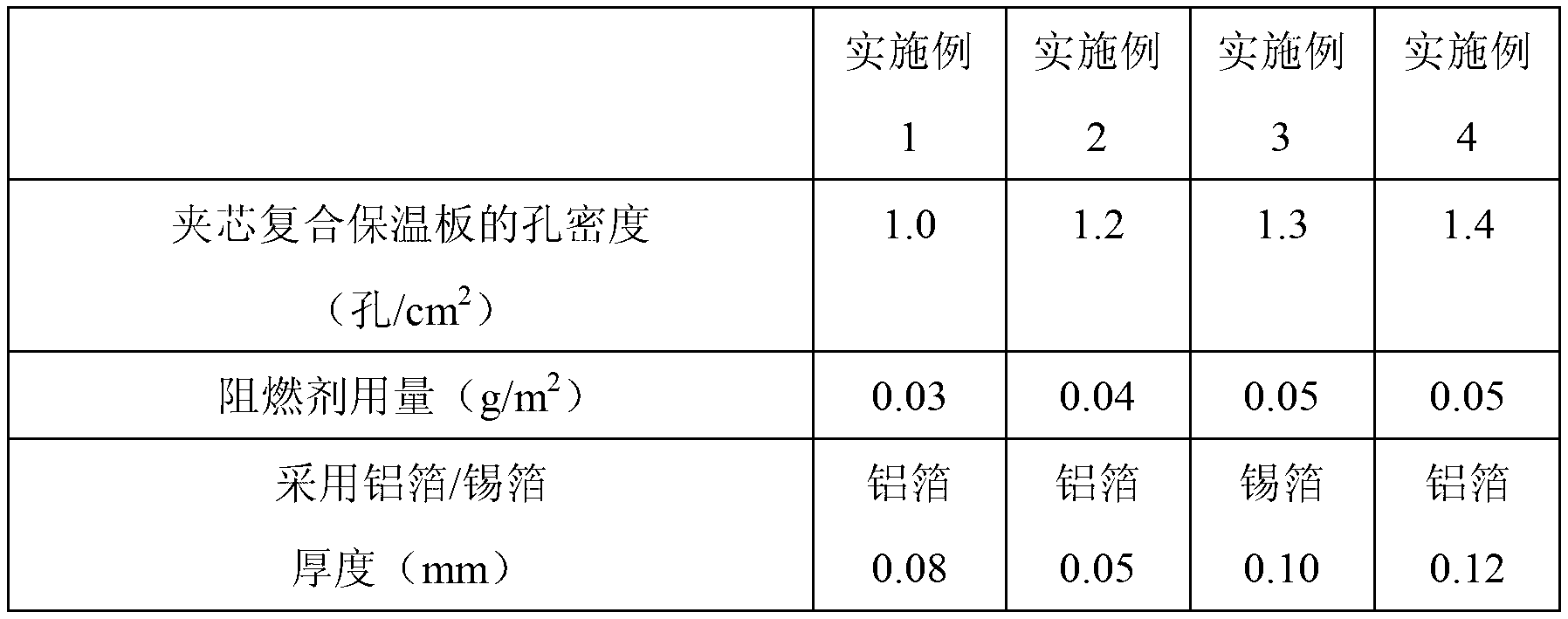

[0057] The process parameters of the preparation method of Examples 2-4 are shown in Table 1, and other unexplained parts are the same as Example 1.

[0058] The physical and chemical parameters of the sandwich composite insulation board described in Table 1 embodiment 1-4 and the process parameters of the preparation method

[0059]

[0060]

[0061] The thermal conductivity test is based on GB / T10295-2008 "The heat flow meter method for the determination of the steady-state thermal resistance and related characteristics of thermal insulation materials".

[0062] The detection method of the sound absorption coefficient adopts the standard GB / T20247-2006 "Sound Absorption Measurement of Acoustic Reverberation Room", the detection equipment: BK4418 type architectural acoustic analyzer; the ambient temperature is 21°C, and the humidity is 72%.

[0063] Combustion performance is based on GB8624-2006 "Classification of Combustion Performance of Building Materials and Product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com