Rankine cycling and seawater freshening dual-efficiency waste heat recovery system

A waste heat recovery system and Rankine cycle technology, applied in seawater treatment, general water supply saving, heating water/sewage treatment, etc., can solve problems such as deterioration and reduction of deadweight tonnage, achieve efficient recovery, improve fuel economy, and improve navigation The effect of mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The principle and system of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. It should be noted that this embodiment is illustrative rather than restrictive, and does not limit the protection scope of the present invention.

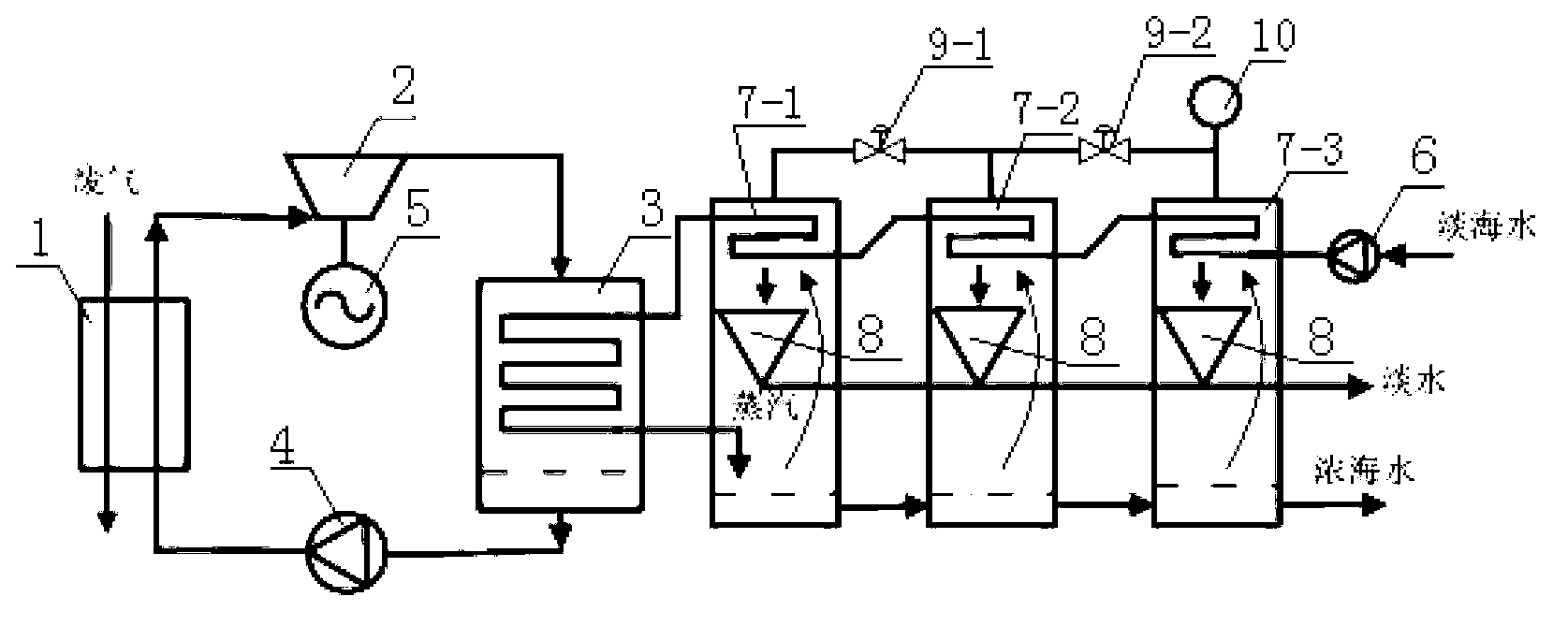

[0010] Rankine cycle seawater desalination double-effect waste heat recovery system, the system structure features are: the working medium side of the evaporator 1, the steam turbine 2, the working medium side of the condenser 3 and the working medium pump 4 are connected in sequence, and the steam turbine and the generator have 5 shafts connected to form a steam Rankine cycle thermal power generation system. The high-temperature exhaust gas discharged from the engine directly exchanges heat with the working fluid through the gas side of the evaporator, and the water pump 6 is connected in series with the seawater pipes of the third, second, and first-stage flash chambers 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com