Double-junction depth photodiode for fluorescence detection

A photodiode and deep junction technology, applied in the field of fluorescence detection photosensitive sensing units, can solve the problems of narrow spectral response range, wide spectral response range, and large dark current noise, and achieve high sensitivity, wide spectral response, and low dark current. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

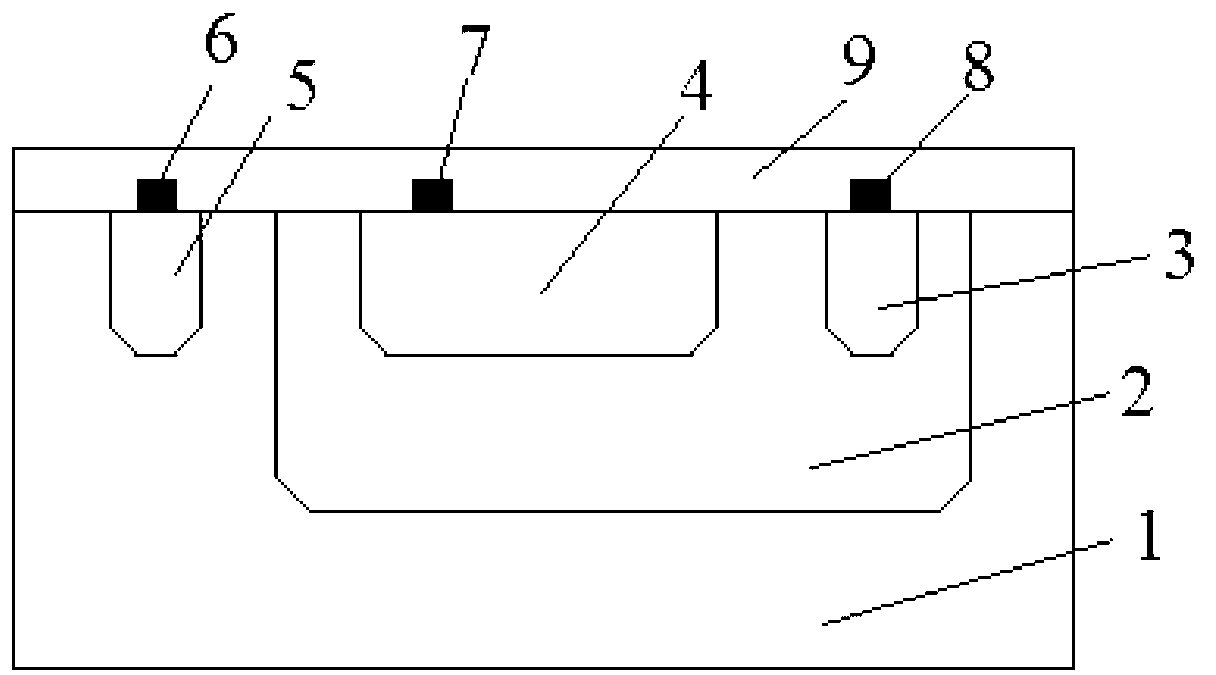

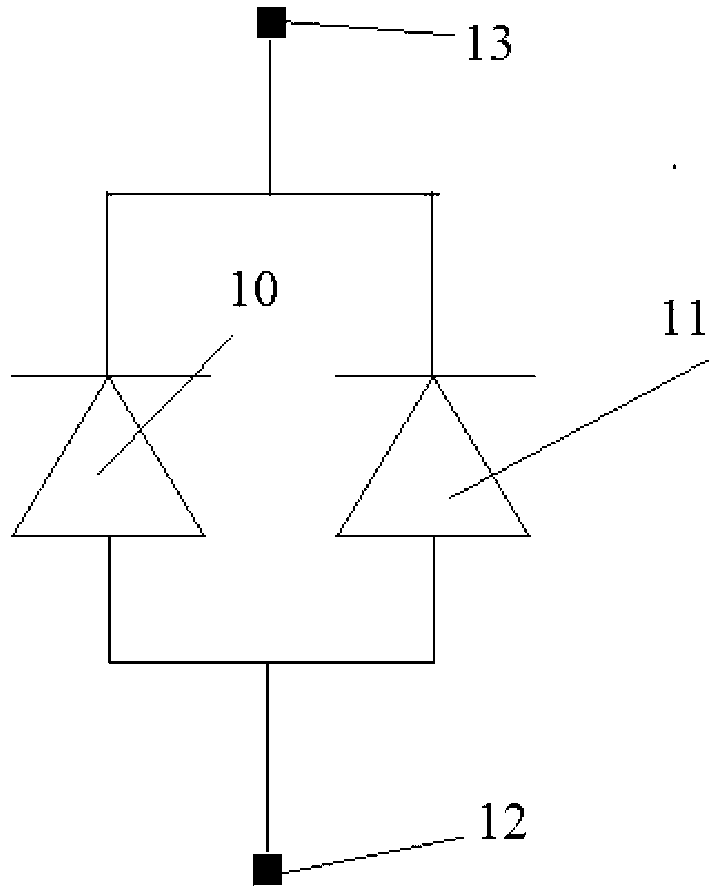

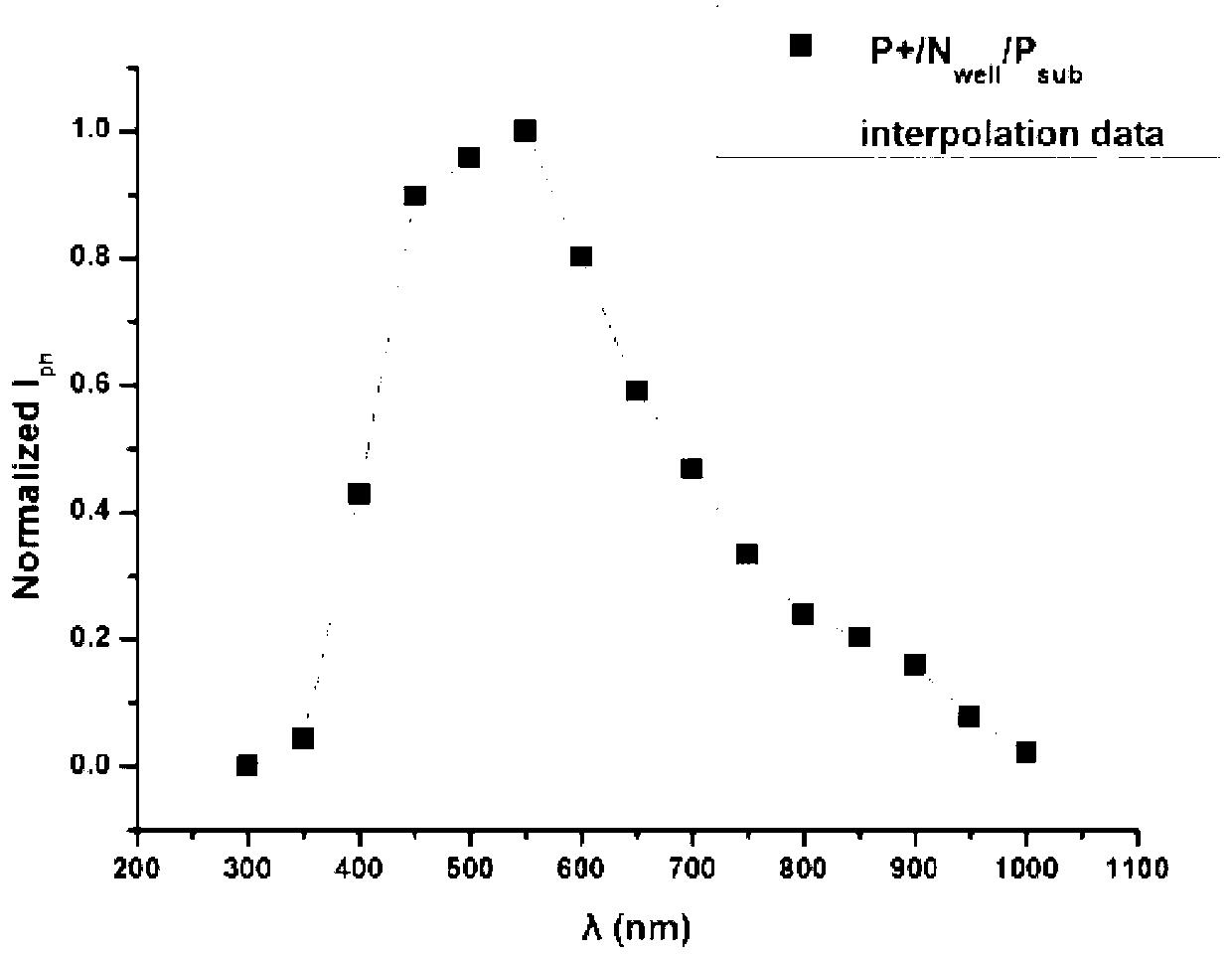

[0017] refer to figure 1 , a double-junction deep PN junction photodiode based on a standard CMOS process, comprising a deep junction PN junction photodiode composed of a semiconductor silicon P-type substrate 1 and an N-type well 2; a P-type source-drain injection 4 and the N-type well Shallow junction PN junction photodiode composed of type well 2. The semiconductor silicon P-type substrate 1 is the anode of the deep-junction PN junction photodiode, and the N-type well 2 is the cathode of the deep-junction PN junction photodiode; the P-type source-drain injection 4 is the The anode of the shallow junction PN junction photodiode, the N-type well 2 is the cathode of the shallow junction PN junction photodiode. The semiconductor silicon P-type substrate 1 forms a heavily doped ohmic contact through a P-type source-drain implant 5, and leads out through a metal contact hole 6, and the N-type well 2 forms a heavily-doped ohmic contact through an N-type source-drain implant 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com