Composite lithium battery diaphragm and preparation method thereof

A battery diaphragm and lithium composite technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of poor temperature resistance and low porosity of lithium battery diaphragms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

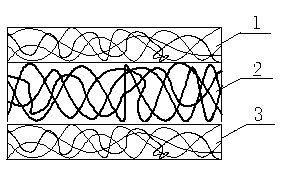

[0027] Such as figure 1 As shown, the composite lithium battery separator of this embodiment is composed of the upper nanofiber membrane 1 , the middle microfiber membrane 2 and the lower nanofiber membrane 3 . The fiber diameter of the upper nanofiber membrane 1 and the lower nanofiber membrane 3 is 100nm, the fiber diameter of the middle microfiber membrane is 2.5μm, and the total thickness of the composite lithium battery separator is 15μm.

[0028] Preparation:

[0029] Polyimide is used as the polymer material of the upper nanofiber membrane and the lower nanofiber membrane, and styrene-maleic anhydride copolymer is used as the polymer material of the middle microfiber membrane, and by solution electrospinning, Prepare the upper nanofiber membrane, the middle microfiber membrane and the lower nanofiber membrane respectively, and then unwind and stack them in sequence, and then place them in a curing furnace at 150°C to remove the solvent, and finally control the pressure...

Embodiment 2

[0036] The composite lithium battery separator of this embodiment is composed of an upper nanofiber membrane, a middle microfiber membrane and a lower nanofiber membrane. The fiber diameters of the upper nanofiber membrane and the lower nanofiber membrane are 120nm, the fiber diameter of the middle microfiber membrane is 2.9μm, and the total thickness of the composite lithium battery separator is 25μm.

[0037] Preparation:

[0038]Polyvinylidene fluoride is used as the polymer material of the upper nanofiber membrane and the lower nanofiber membrane, polyvinyl alcohol is used as the polymer material of the middle microfiber membrane, and the upper nanofiber membrane is prepared by solution electrospinning. The fiber membrane, the middle layer of microfiber membrane and the lower layer of nanofiber membrane are then unrolled and stacked in sequence, and then placed in a curing furnace at 240°C to remove the solvent, and finally roll-formed at 210°C by temperature-controlled pr...

Embodiment 3

[0045] The composite lithium battery separator of this embodiment is composed of an upper nanofiber membrane, a middle microfiber membrane and a lower nanofiber membrane. The fiber diameter of the upper nanofiber membrane and the lower nanofiber membrane is 138nm, the fiber diameter of the middle microfiber membrane is 3.4μm, and the total thickness of the composite lithium battery separator is 40μm.

[0046] Preparation:

[0047] Polyarylene sulfide sulfone is used as the polymer material of the upper nanofiber membrane and the lower nanofiber membrane, polyurethane is used as the polymer material of the middle microfiber membrane, and the upper nanofibers are respectively prepared by solution electrospinning The membrane, the middle layer of microfiber membrane and the lower layer of nanofiber membrane are then unrolled and stacked in sequence, and then placed in a curing furnace at 200°C to remove the solvent, and finally roll-formed at 180°C by temperature-controlled press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com