Water-in-oil-in-water adjuvant vaccine and preparation method thereof

A water-in-oil-in-water and adjuvant technology, which is applied in the field of vaccines, can solve the problems of adverse effects on animal carcass quality, difficulty in providing protective antibodies, and slow speed of protective antibodies, achieving rapid immune protection and good local absorption by injection. , the effect of maximizing bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

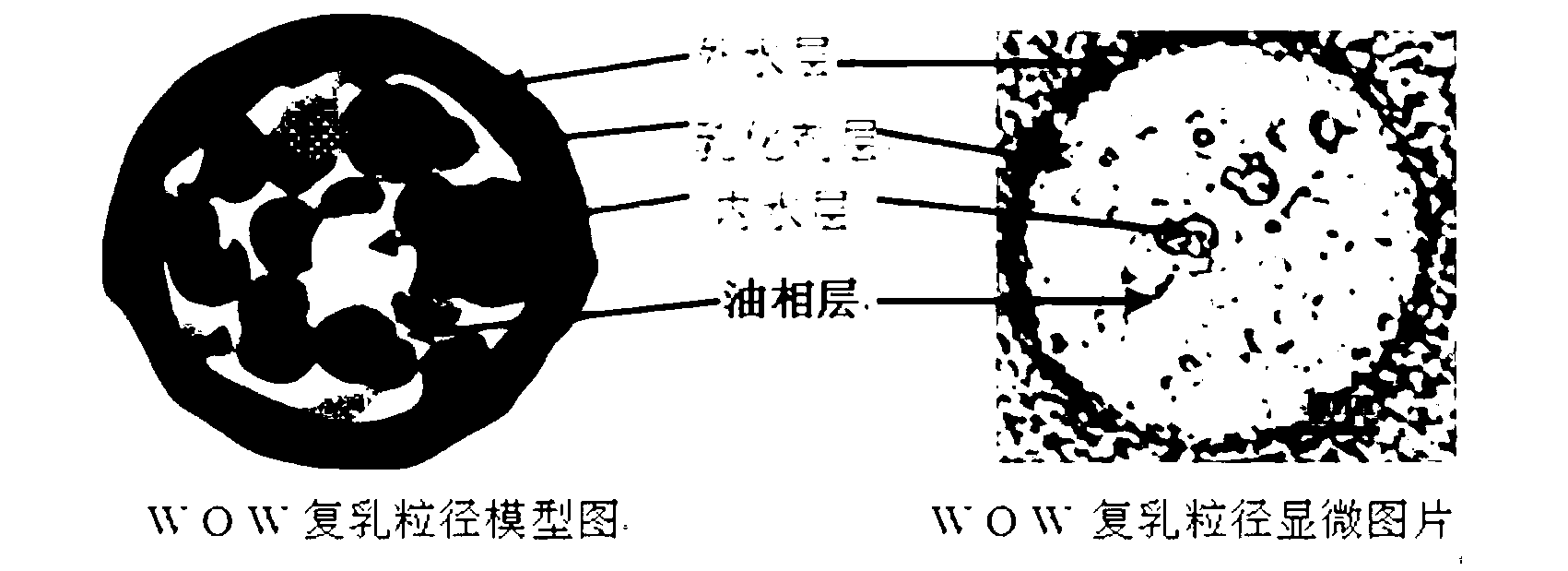

[0039] A water-in-oil-in-water type adjuvanted vaccine, which is composed of an internal water phase, an intermediate oil phase for coating the internal water phase, and an intermediate oil phase for coating the internal water phase;

[0040] The components in the external water phase, based on the total volume of the water-in-oil-in-water type adjuvant vaccine raw materials, the ratio is: compound surfactant 1%, Tween-80 0.3%, physiological saline 15.5%;

[0041] The components in the middle oil phase, based on the total volume of the water-in-oil-in-water type adjuvant vaccine raw materials, the ratio is: span 80 3%, aluminum hardate 8.5 g / L, imported white oil 47%;

[0042]The components in the internal water phase, based on the total volume of the water-in-oil-in-water type adjuvant vaccine raw materials, the ratio is: 0.15g / mL astragalus polysaccharide injection 2%, Tween-80 1.2%, and the balance is Live antigen solution; the total volume percentage of the water-in-oil-in...

Embodiment 2

[0050] A water-in-oil-in-water type adjuvanted vaccine, which is composed of an internal water phase, an intermediate oil phase for coating the internal water phase, and an intermediate oil phase for coating the internal water phase;

[0051] The components in the external water phase, based on the total volume of the water-in-oil-in-water type adjuvant vaccine raw materials, the ratio is: 0.5% compound surfactant, 0.6% Tween-20, 18% normal saline;

[0052] The components in the middle oil phase, based on the total volume of the water-in-oil-in-water type adjuvant vaccine raw materials, the ratio is: span 60 2%, aluminum hardate 10 g / L, imported white oil 30%;

[0053] The components in the internal water phase, based on the total volume of the water-in-oil-in-water type adjuvant vaccine raw materials, the ratio is: 0.1g / mL astragalus polysaccharide injection 1.5%, Tween-80 0.5%, the balance is Live antigen solution; the total volume percentage of the water-in-oil-in-water typ...

Embodiment 3

[0061] A water-in-oil-in-water type adjuvanted vaccine, which is composed of an internal water phase, an intermediate oil phase for coating the internal water phase, and an intermediate oil phase for coating the internal water phase;

[0062] The components in the external water phase, based on the total volume of the water-in-oil-in-water type adjuvant vaccine raw materials, the ratio is: compound surfactant 1.51%, Tween-60 0.5%, physiological saline 9%;

[0063] The components in the middle oil phase, based on the total volume of the water-in-oil-in-water type adjuvant vaccine raw materials, the ratio is: span 80 4%, aluminum hardate 5 g / L, imported white oil 50%;

[0064] The components in the internal water phase, based on the total volume of the water-in-oil-in-water type adjuvant vaccine raw materials, the ratio is: 0.13g / mL astragalus polysaccharide powder aqueous solution 2.5%, Tween-20 1.5%, the balance is Live antigen solution; the total volume percentage of the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com