Treatment method of wastewater containing dimethylamine

A treatment method and technology of dimethylamine, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. Low oxygen demand and other problems to achieve the effect of reducing wastewater discharge, improving reuse rate and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

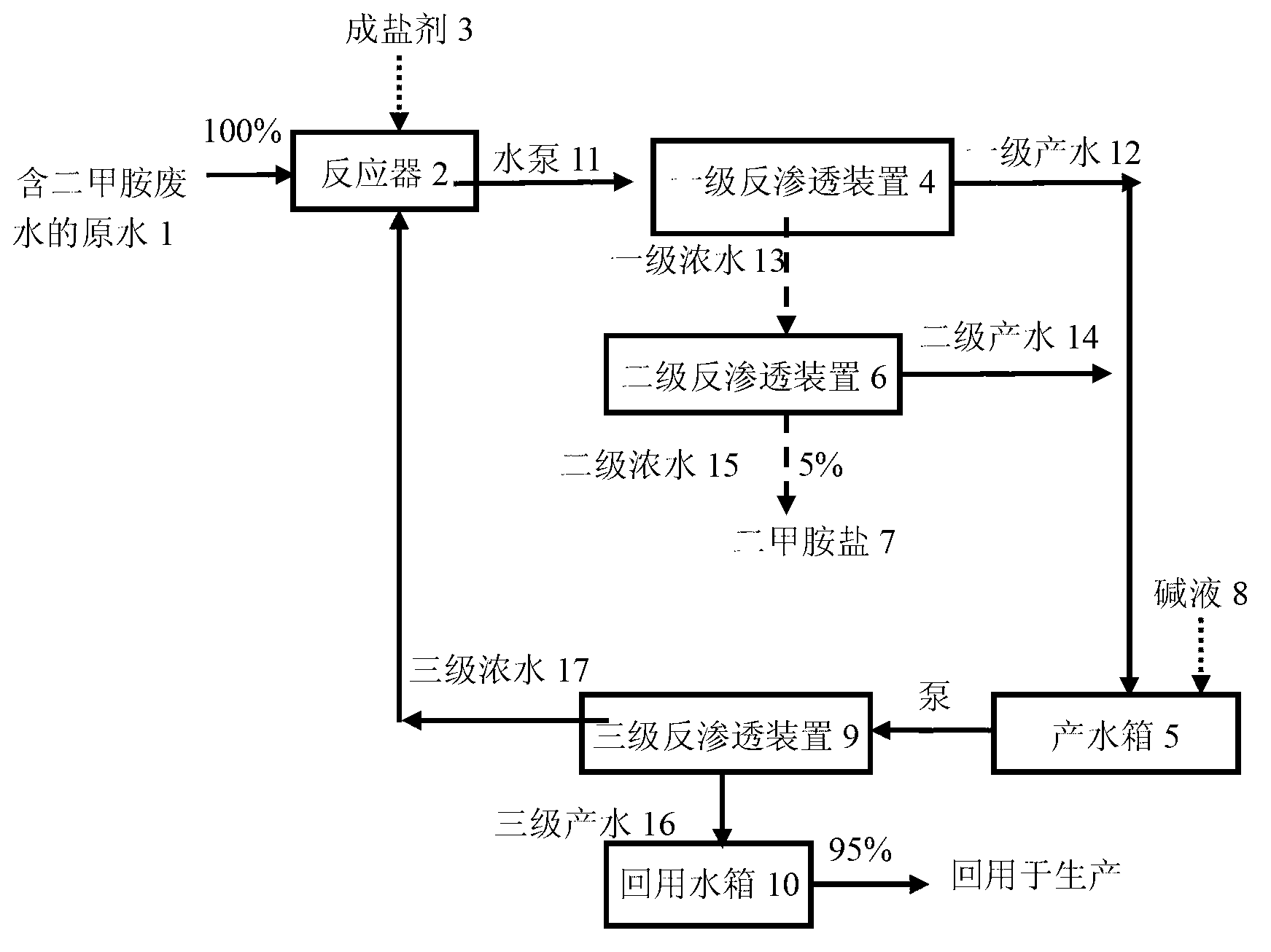

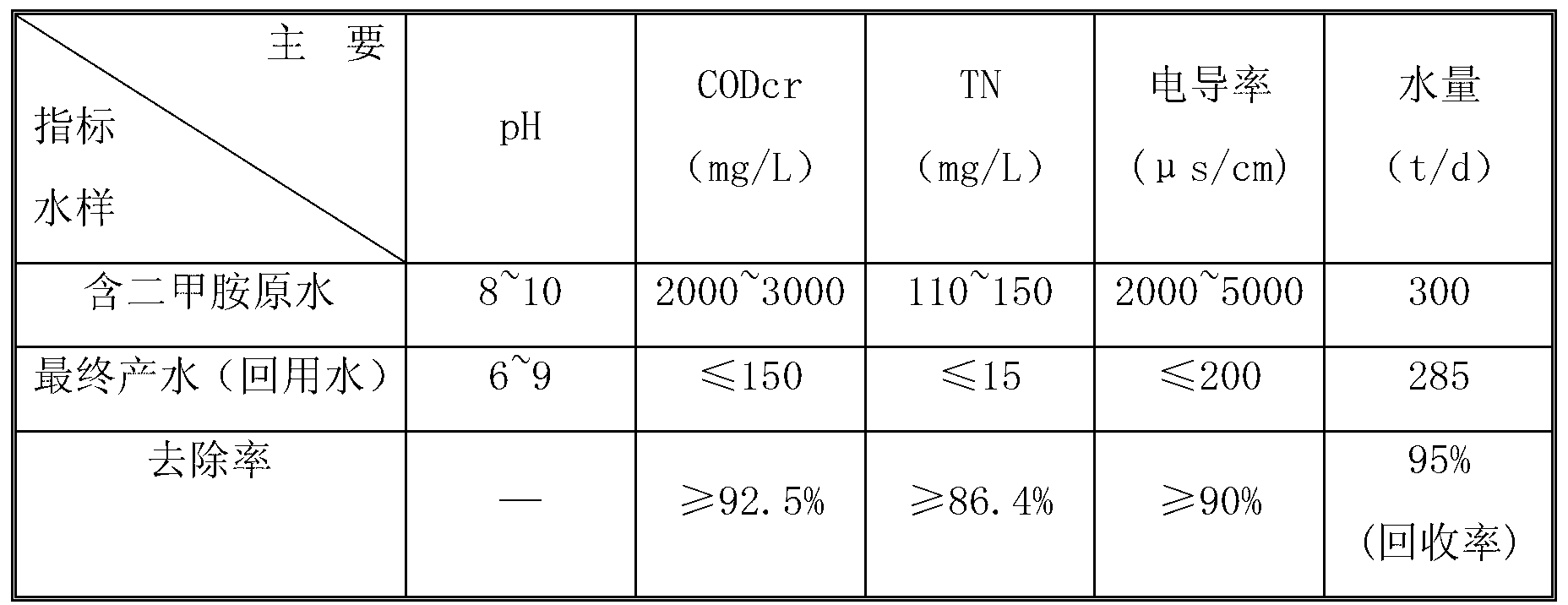

[0037] Dimethylamine wastewater is pumped into the raw water tank from the wastewater tank, and an appropriate amount of sulfuric acid is metered to adjust the pH of the wastewater to 3-4. After the adjusted wastewater is pressurized by a booster pump, it enters degreasing pretreatment and ultrafiltration for filtration. , remove most of the SS in the water, meet the influent water quality standard of RO membrane treatment, and then enter the first-level RO membrane concentration system. The primary concentrated water is discharged into the primary concentrated water tank.

[0038] The wastewater from the primary concentrated water tank is pressurized by the booster pump and enters the security filter for filtration to remove most of the SS in the water to meet the influent water quality standard for RO membrane treatment, and then enters the secondary RO membrane concentration system, and the wastewater passes through the secondary After RO membrane reverse osmosis filtration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com