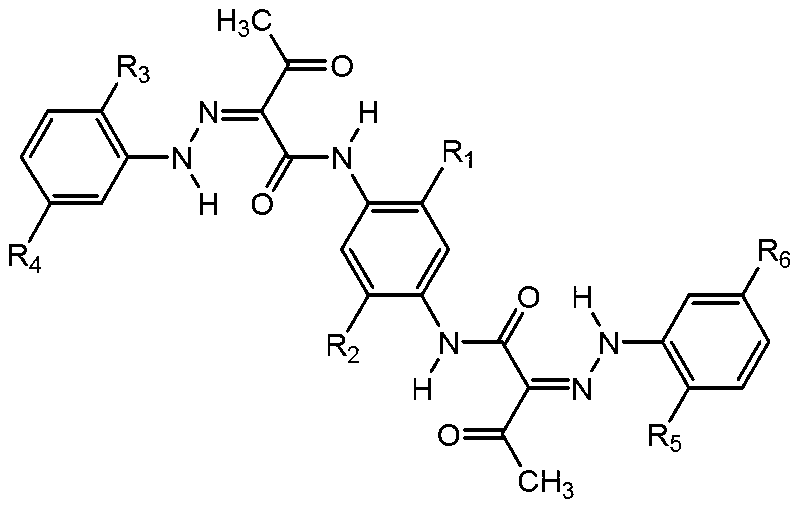

Preparation method of double-acetyl-p-phenylenediamine bisazo compound

A technology of disazo compound and diacetoacetyl is applied in the field of preparation of disazo compound, can solve problems such as large raw materials, three wastes, waste, etc., and achieve the effects of reducing difficulty, avoiding decomposition of diazonium salt, and avoiding aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

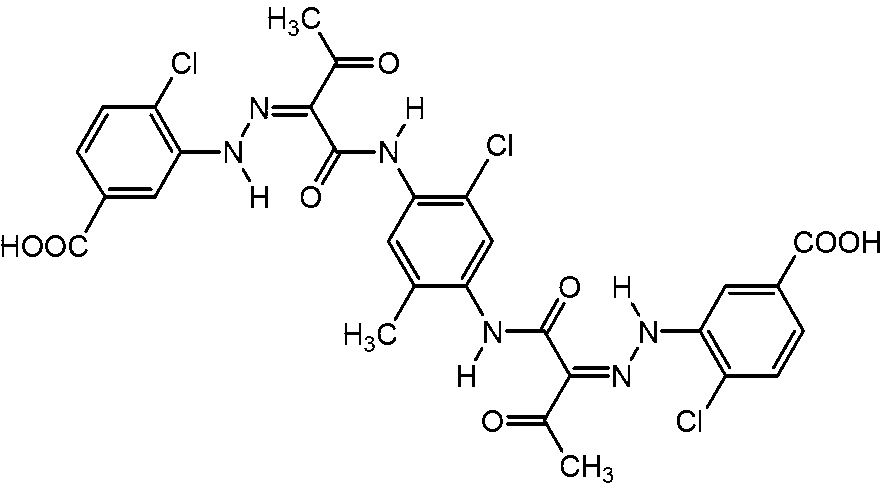

Embodiment 1

[0044] 20.9 parts of dimethyl 2-aminoterephthalate, 39.9 parts of 31% hydrochloric acid and 150 parts of water are beaten together at room temperature. Aqueous suspension of hydrochloride salt of dimethyl 2-aminoterephthalate was formed. Add ice and cool down to 0°C, add 6.9 parts of sodium nitrite to carry out diazotization reaction. A clear diazonium salt solution was obtained.

[0045] 13.8 parts of diacetoacetyl-p-phenylenediamine were stirred with 4.4 parts of sodium hydroxide and 100 parts of water to obtain a transparent solution. Add 0.2 part of emulsifier OS-15 and 0.1 part of dodecyl dimethyl benzyl ammonium chloride and stir well. Add 9 parts of sodium bicarbonate to obtain a coupling liquid; to be coupled.

[0046] Take out 10% of the total weight of the diazonium salt solution and put it into the reactor as the bottom liquid, add sodium acetate, adjust the pH to 3, and the temperature is 15°C. Under stirring, add the remaining diazonium salt solution and coupl...

Embodiment 2

[0061] The difference from Example 1 is:

[0062] The diazonium salt solution used as the bottom solution during the coupling reaction is 5% of the total amount of the diazonium salt solution. The final molar consumption ratio of dimethyl 2-aminoterephthalate and diacetoacetyl-p-phenylenediamine is 2:1.01,

[0063] Based on diacetoacetyl-p-phenylenediamine, the yield is 97.5%

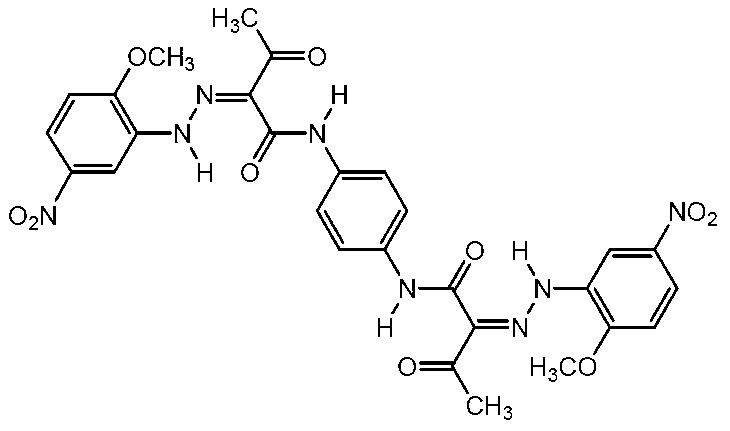

Embodiment 3

[0065] 16.8 parts of 2-methoxy-4-nitroaniline, 29.4 parts of 31% hydrochloric acid and 60 parts of water were beaten together for 2 hours. Add ice and cool down to 0°C, add 6.9 parts of sodium nitrite to carry out diazotization reaction.

[0066] 13.8 parts of diacetoacetyl-p-phenylenediamine were stirred with 4.4 parts of sodium hydroxide and 100 parts of water to obtain a transparent solution. Add 0.2 part of emulsifier OS-15 and 0.1 part of dodecyl dimethyl benzyl ammonium chloride and stir well. Add 7 parts of sodium bicarbonate to be coupled.

[0067] Take out 10% of the total weight of the diazonium salt solution and put it into the reactor as the bottom liquid, add sodium acetate, adjust the pH to 4, and the temperature is 8°C. Within 2 hours, continuously and slowly add the remaining diazonium salt solution and the coupling solution to the base solution at a molar ratio of 2:1 until all the diazonium salts are added. Slowly add the remaining coupling solution until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com