Hydraulic type driving system for engineering driller

A technology for engineering drilling rigs and drive systems, applied in rotary drilling rigs, drilling equipment, earthwork drilling and production, etc., can solve problems such as difficulty in tower installation, inconvenient movement and transfer, poor fixation and safety of towers, and achieve economical use cost and labor cost, optimize equipment layout space, and improve the effect of drilling construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

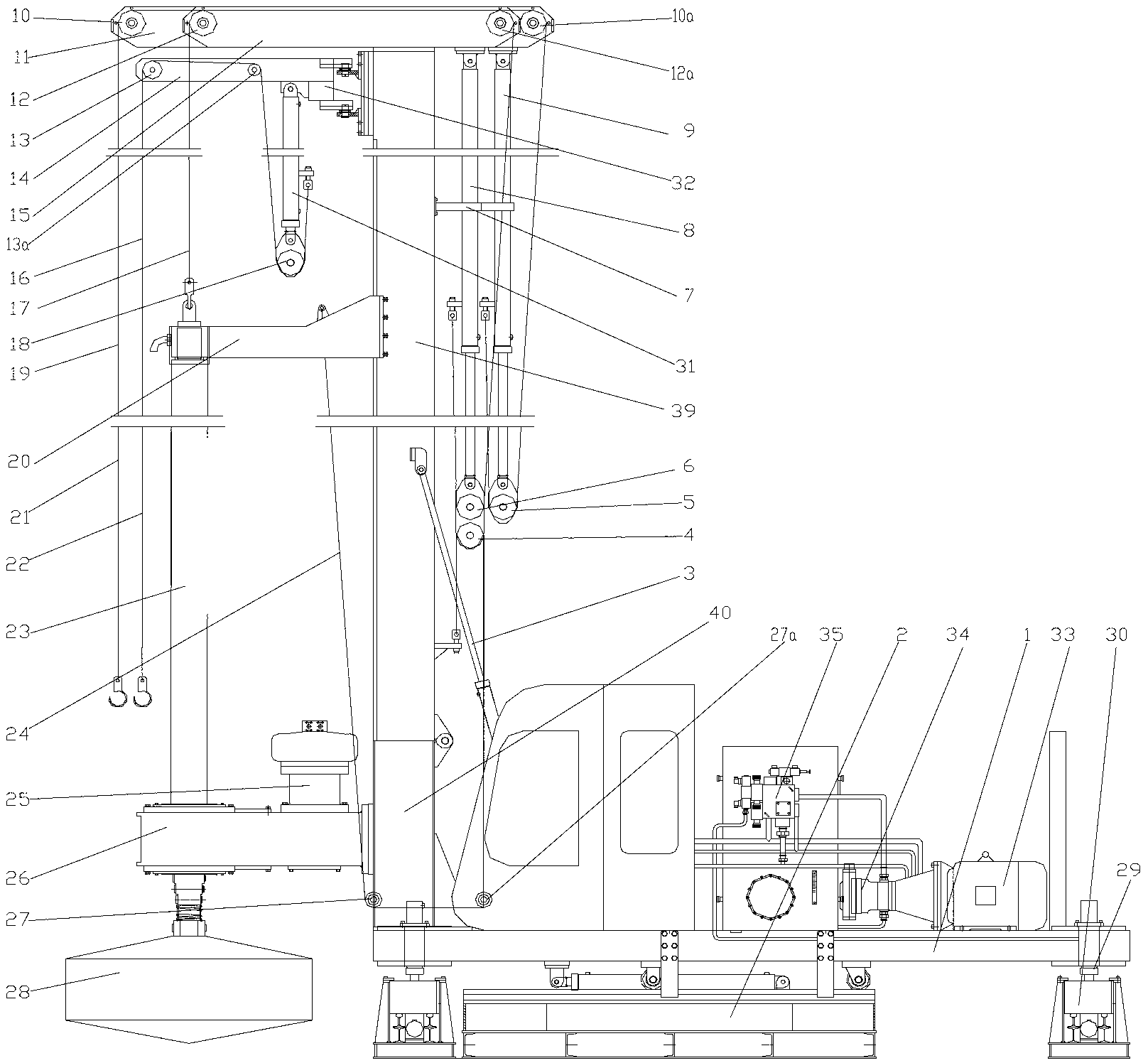

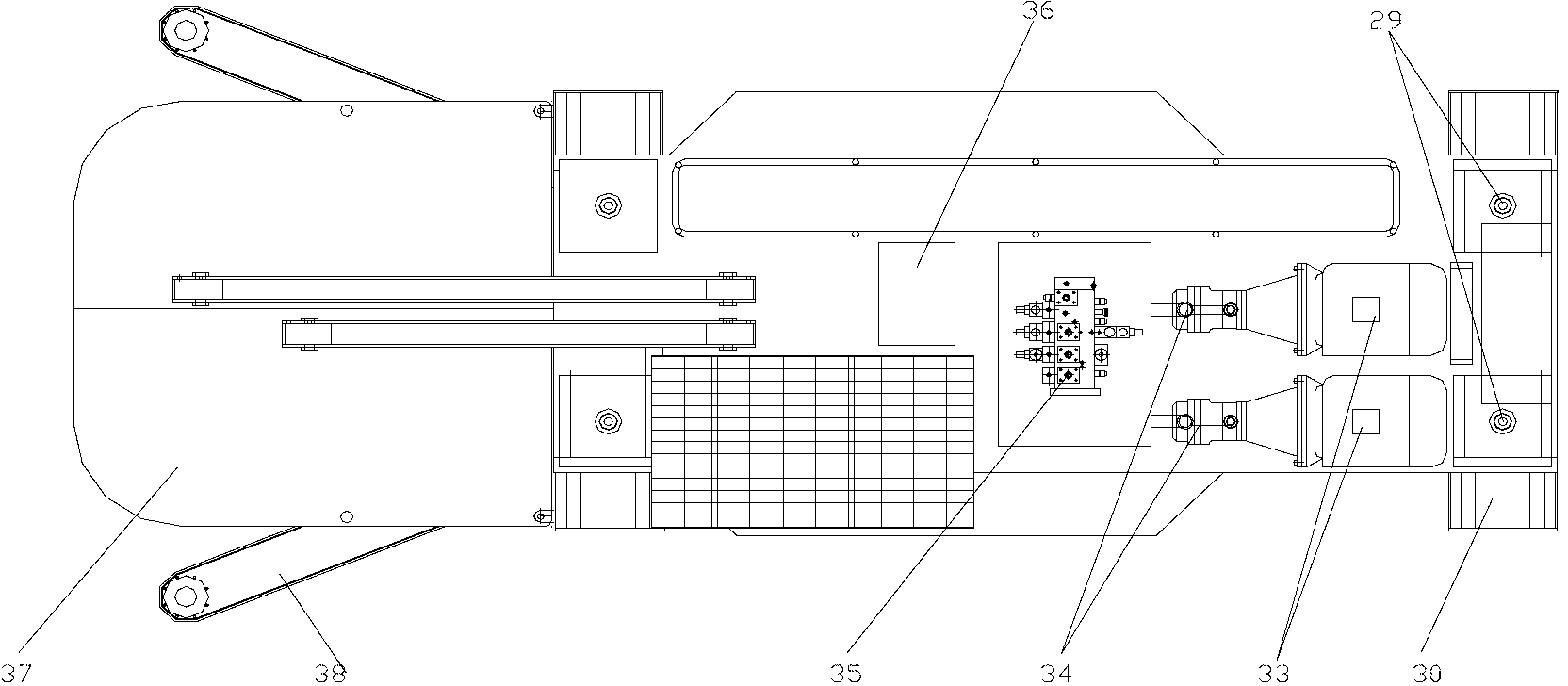

[0023] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 As shown in the figure: the engineering drilling rig hydraulic drive system of this embodiment includes a hydraulic pump 34, a control assembly 36 and a drilling drive system driven by the hydraulic pump 34 under the control of the control assembly 36, the drilling The driving system includes a drilling hydraulic cylinder 8 and a hydraulic motor 25, the power output end of the hydraulic motor 25 is driven and matched with the power head 26 of the engineering drilling rig, and the drilling hydraulic cylinder 8 drives the drilling bit assembly of the engineering drilling rig to rise through the drilling pulley block or descending movement; the control assembly 36 is an existing hydraulic cylinder control assembly, which is controlled by the solenoid valve group 35, and the specifications and models of the solenoid valve are set according to the needs, and the stroke and speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com