Measuring device and measuring method for tiny surface defect through post-magnification digital holographic microscopy

A digital holographic microscope and measuring device technology, which is applied in the direction of measuring devices, optical devices, and optical testing of flaws/defects. It can solve problems such as low precision, high labor costs, and slow detection speed, and achieve good dynamic performance. Effect of suppressing stray light and improving signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

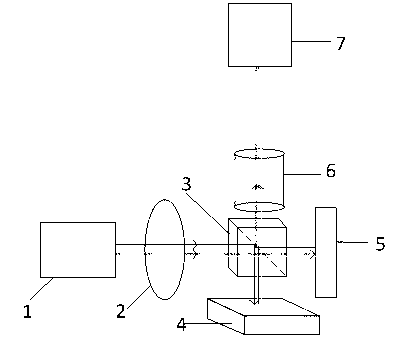

[0021] Such as figure 1 As shown, a post-magnification digital holographic microscopic surface micro-defect measurement device includes a laser 1, a convex lens 2, a first dichroic prism 3, a reference mirror 5, a microscopic objective lens 6 and a CCD camera 7; the convex lens 2, the first The horizontal central axis of a dichroic prism 3 and the reference mirror 5 is on the same horizontal straight line as the central axis of the light beam emitted by the laser 1; The camera 7 is on the same vertical line, and the central axis of the light beam sent by the laser intersects the central point of the beam splitting prism; the vertical central axis of the laser 1, the convex lens 2 and the first beam splitting prism 3 are parallel to each other; the first beam splitting The horizontal central axes of the prism 3, the microscopic objective lens 6 and the CCD camera 7 are parallel to each other.

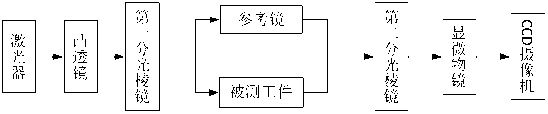

[0022] Such as image 3 As shown, a post-amplification digital holographic microsc...

Embodiment 2

[0025] This embodiment is basically the same as Embodiment 1, the difference is:

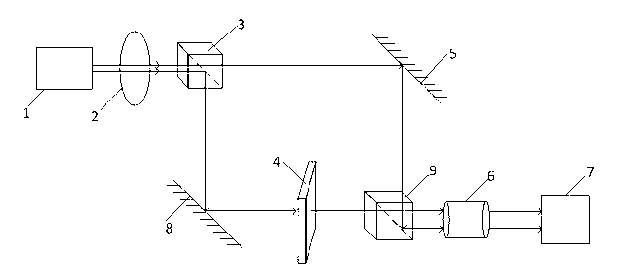

[0026] Such as figure 2 As shown, the device also includes a reflecting mirror 8 and a second dichroic prism 9; the horizontal central axis of the convex lens 2 and the first dichroic prism 3 is on the same horizontal straight line as the central axis of the beam emitted by the laser 1; 8. The position to be detected of the workpiece 4 to be measured, the horizontal central axis of the second dichroic prism 9, the microscopic objective lens 6 and the CCD camera 7 are on the same horizontal straight line as the central axis of the measuring beam; the mirror 8 is 45 to the horizontal axis Placement; the vertical central axes of the laser 1, the convex lens 2, the first beam splitting prism 3, the workpiece to be measured 4, the second beam splitting prism 9, the microscopic objective lens 6 and the CCD camera 7 are parallel to each other.

[0027] Such as Figure 4As shown, the method also incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com