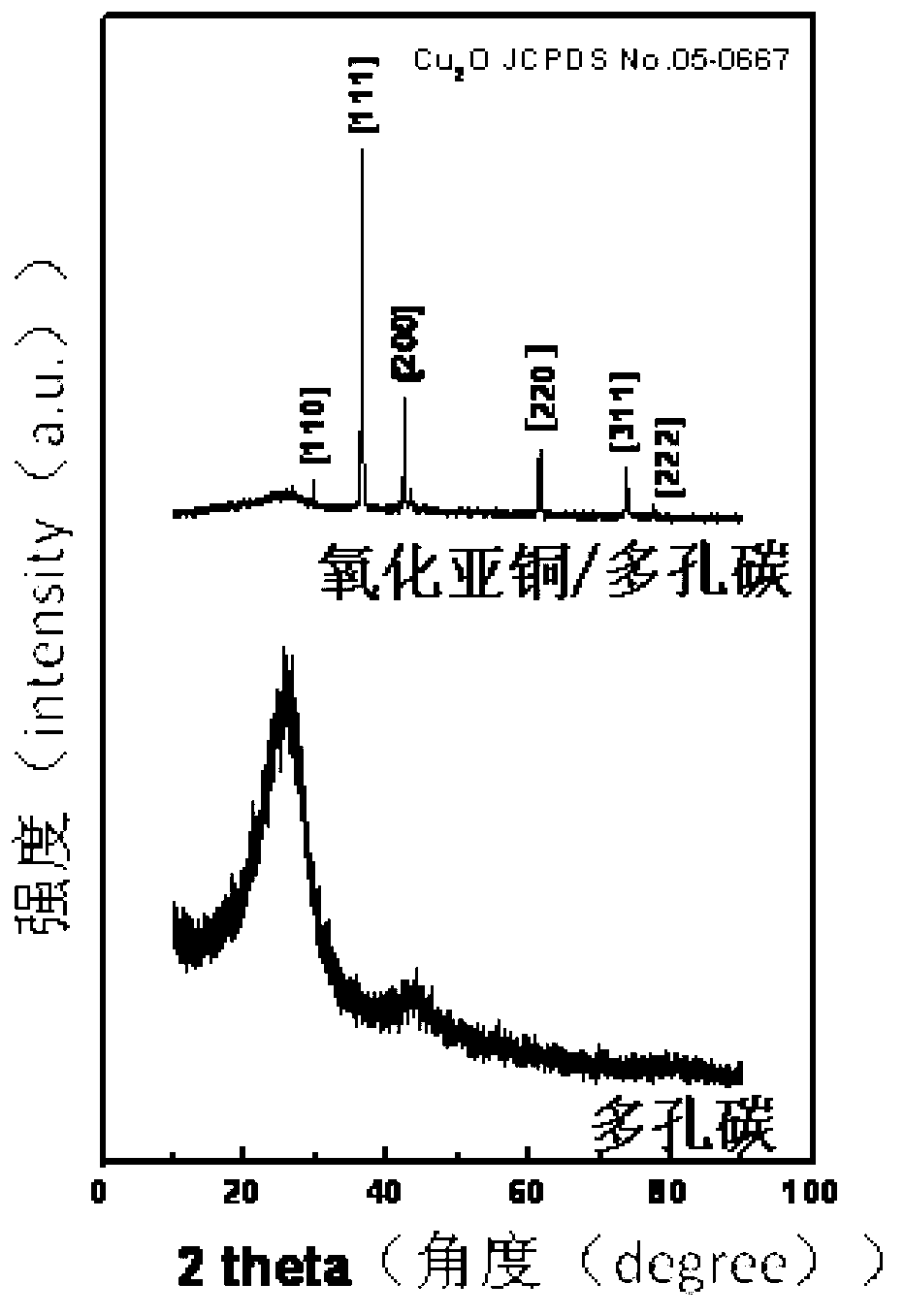

Cuprous oxide/porous carbon composite material as lithium ion battery cathode material and preparation method thereof

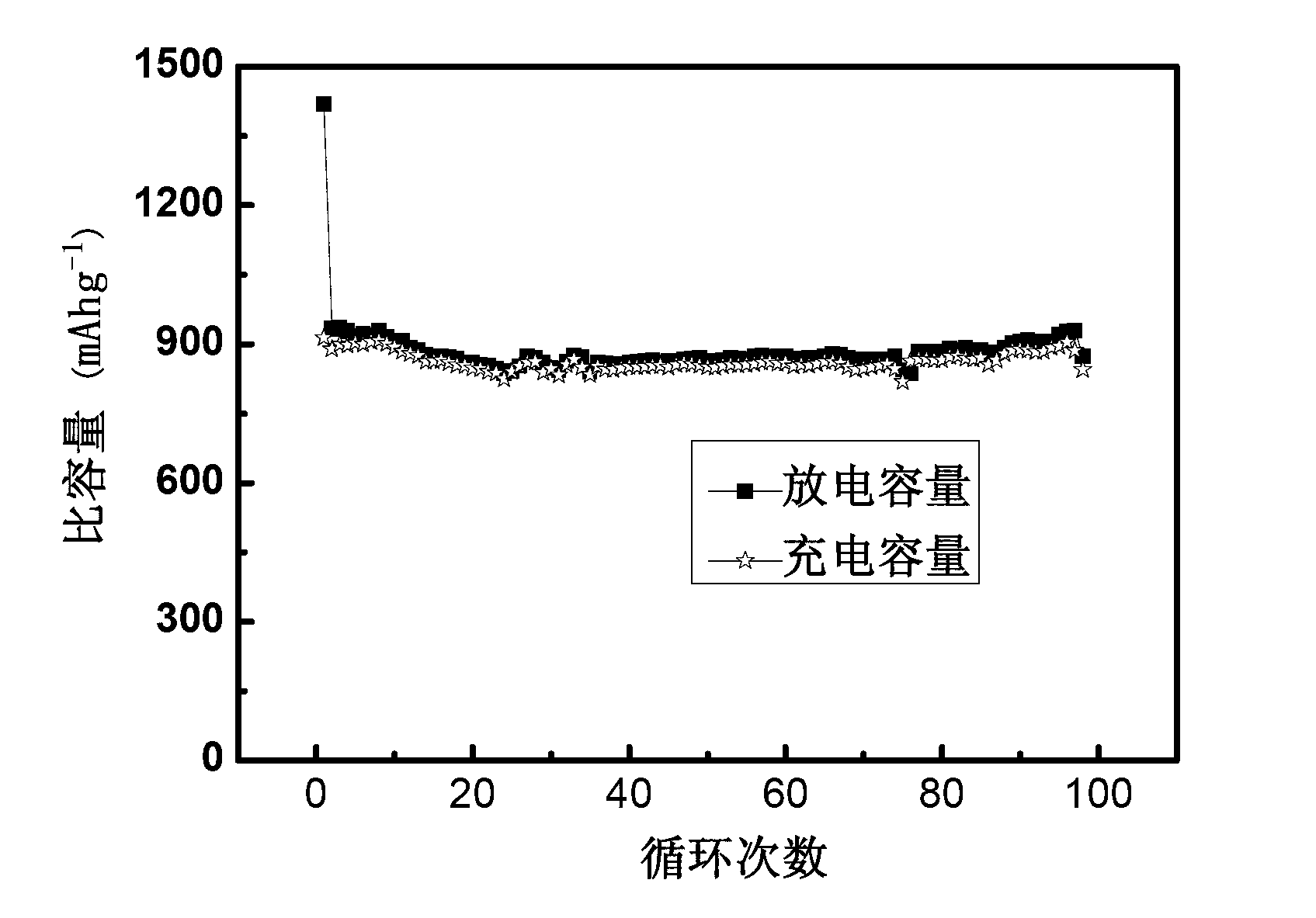

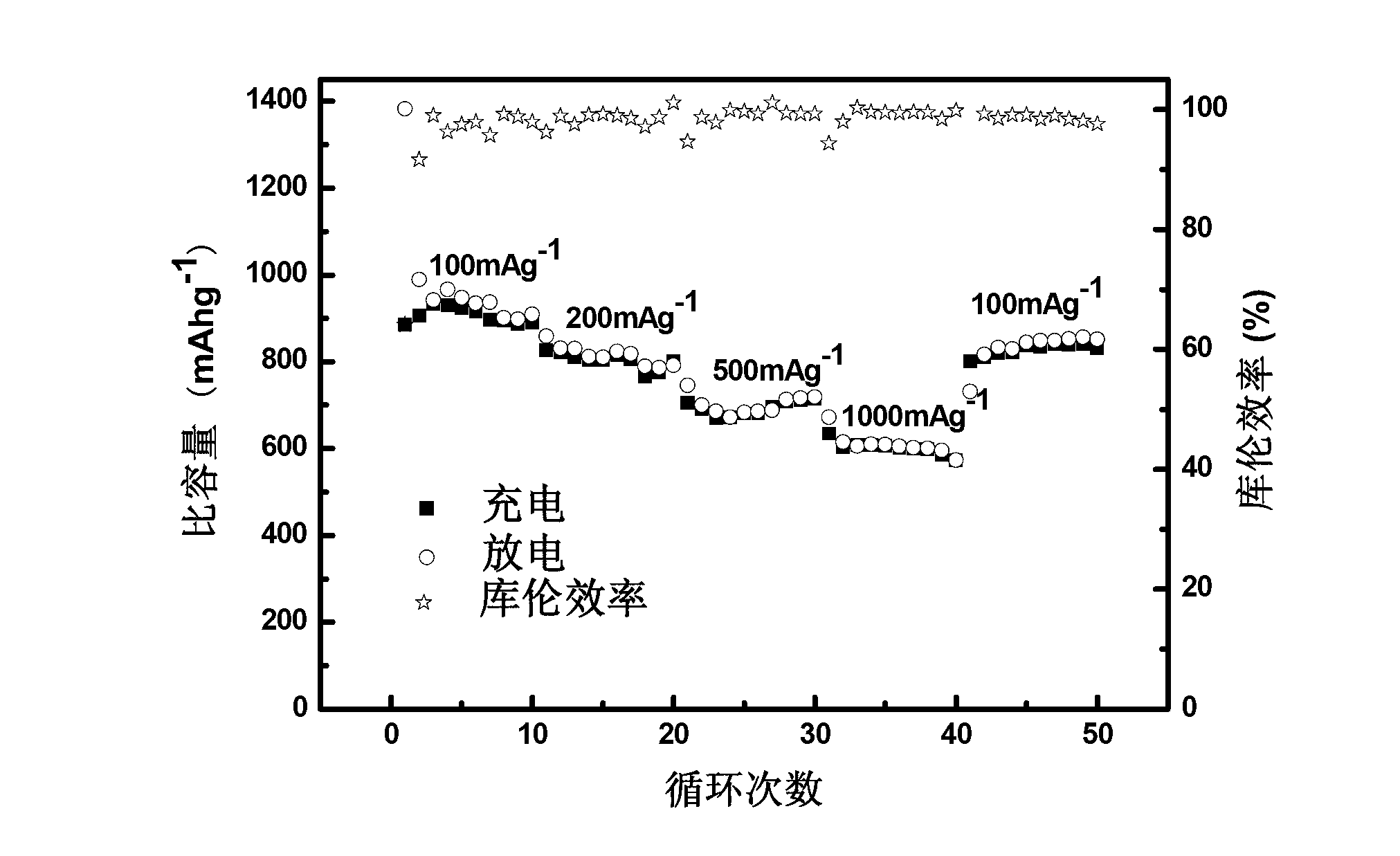

A lithium-ion battery, cuprous oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor conductivity, fast capacity decay, unsatisfactory rate performance, etc., achieve high rate performance, avoid chalking and failure. , the effect of excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] A method for preparing a cuprous oxide / porous carbon composite material as a lithium ion battery negative electrode material, the specific preparation steps are as follows:

[0028] 1) Dissolve 1g of copper sulfate in 80mL of deionized water, and magnetically stir to fully dissolve it;

[0029] 2) Add 0.8 g of porous carbon into the solution obtained in step 1), and ultrasonically disperse for 30 minutes to fully disperse the porous carbon in the solution;

[0030] 3) Add 0.72g of sodium hydroxide and 0.65g of glucose into the solution obtained in step 2), the reaction temperature is 80°C, continue to stir for 15 minutes, then stop stirring, age for 60min, and stand to obtain a precipitate;

[0031] 4) washing the precipitate obtained in step 3) with deionized water, suction filtering until the pH of the filtrate is neutral, drying the suction filtration product at 120° C. for 4 hours in vacuum to obtain a cuprous oxide / porous carbon composite material with a nanoporous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com