Divalproex sodium enteric-coated tablet core as well as preparation method and application thereof

A technology of divalproex sodium and enteric-coated tablets, which is applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, active ingredients of anhydride/acid/halide, etc., which can solve the problem of unfavorable pressure granulation and unqualified product quality , high tablet content, etc., to achieve the effects of improving bioavailability in vivo, reducing hygroscopicity, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

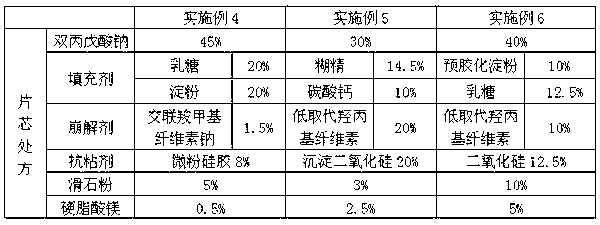

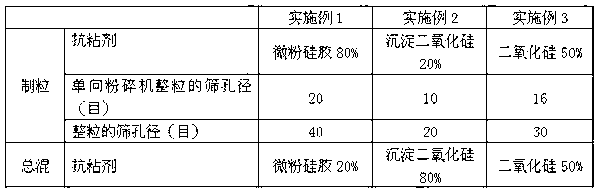

[0056] The composition of divalproex sodium enteric-coated tablet cores in Examples 1-3 is shown in Table 1.

[0057] Table 1 (composition of tablet core)

[0058]

[0059] The preparation method of divalproex sodium enteric-coated tablet core in embodiment 1-3, comprises the following steps:

[0060] 1) Granulation: Divalproex sodium, fillers, disintegrants and 80% (w / w), 20% (w / w), 50% (w / w) of the total anti-adhesive agent After the adhesive is mixed evenly, it is put into a dry-compressed granulator for granulation; the obtained dry-compressed tablet is pulverized by a one-way pulverizer, passed through a 10-20 mesh sieve, and the obtained granules are granulated through a 20-40 mesh sieve;

[0061] 2) Blending and tableting: mix the sized granules with 20% (w / w), 80% (w / w), 50% (w / w) of anti-sticking agent, talcum powder, stearic acid After the magnesium is evenly mixed, it is pressed into tablets.

[0062] The process parameter of embodiment 1-3 is shown in table ...

Embodiment 4-6

[0066] The preparation process of embodiment 4 is the same as embodiment 1; the preparation process of embodiment 5 is the same as embodiment 2; the preparation process of embodiment 6 is the same as embodiment 3.

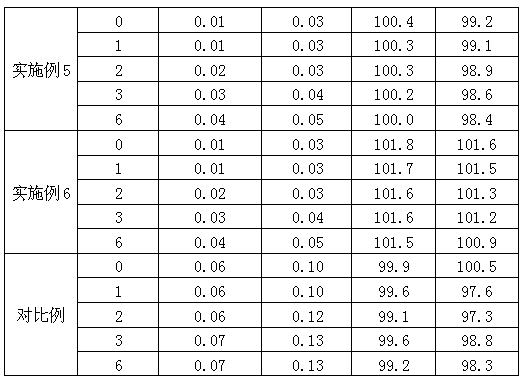

[0067] The process parameter of embodiment 4-6 is shown in table 3.

[0068] table 3

[0069]

[0070] test case 1 Determination of Dissolution Profile of Divalproex Sodium Enteric-coated Tablets

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com