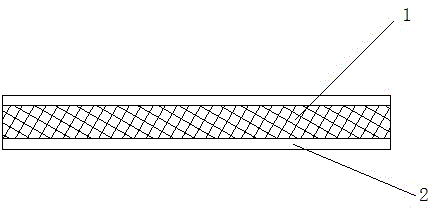

Composite hydrogel dressing and preparation method thereof

A technology of composite hydrogel and gel layer, which is applied in the field of medical materials, achieves the effect of wide application prospect, easy operation and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

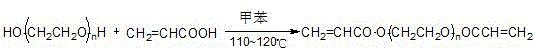

[0028] Preparation of polyethylene glycol diacrylate

[0029] Add 40.0 g (0.1 mol) of PEG-400 and 17.3 g (0.24 mol) of acrylic acid, 87 mL of dehydrating agent to a three-necked flask equipped with a reflux condenser, thermometer and stirrer Toluene, 0.35 g hydroquinone and p-cresol composite inhibitor, 1.7 g catalyst p-toluenesulfonic acid, stirred, heated by electric heating mantle, reacted at reflux temperature (110-120 ℃) for 4 h, and then Replace the thermometer with a water separator, and divide the water for about 2 hours. When no water evaporates, the reaction is terminated. Distill under reduced pressure to remove the solvent and unreacted acrylic acid to obtain a brownish-yellow liquid product, namely the product polyethylene glycol diacrylate (PEGDA).

[0030]

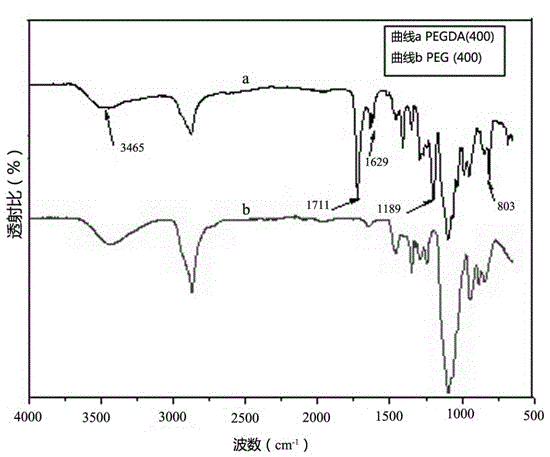

[0031] The infrared absorption characterization of the resulting PEGDA is as follows figure 2 As shown, curve a in the figure represents the absorption curve of PEGDA, and curve b represents the abso...

Embodiment 2

[0058] Mix PEGDA and water in proportion, add ammonium persulfate (APS) aqueous solution and tetramethylethylenediamine (TEMED) aqueous solution, mix evenly, coat on the mesh high-density polyethylene layer, and polymerize in an oven , to prepare composite hydrogel dressings.

[0059] The properties of the resulting hydrogels are as follows:

[0060] (1) Gel time (Table 7)

[0061]

[0062] As can be seen from the above table 7, the gel time shortens with the increase of the initiator concentration, shortens with the increase of the gel temperature, shortens with the increase of the concentration of the PEG aqueous solution, and decreases with the increase of the molecular weight of the PEG main chain. increased and shortened.

[0063] (2) Equilibrium water content (Table 8)

[0064]

[0065] It can be seen from the above table 8 that the equilibrium water content increases with the increase of the molecular weight of the PEG main chain, decreases with the increase of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com