Preparation method and rheological property test method of reinforced toughened nylon 11 ternary composite material

A technology for composite materials and rheological properties, which is applied in the field of preparation and rheological properties testing of reinforced and toughened nylon 11 ternary composite materials, and can solve problems such as lack of improvement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

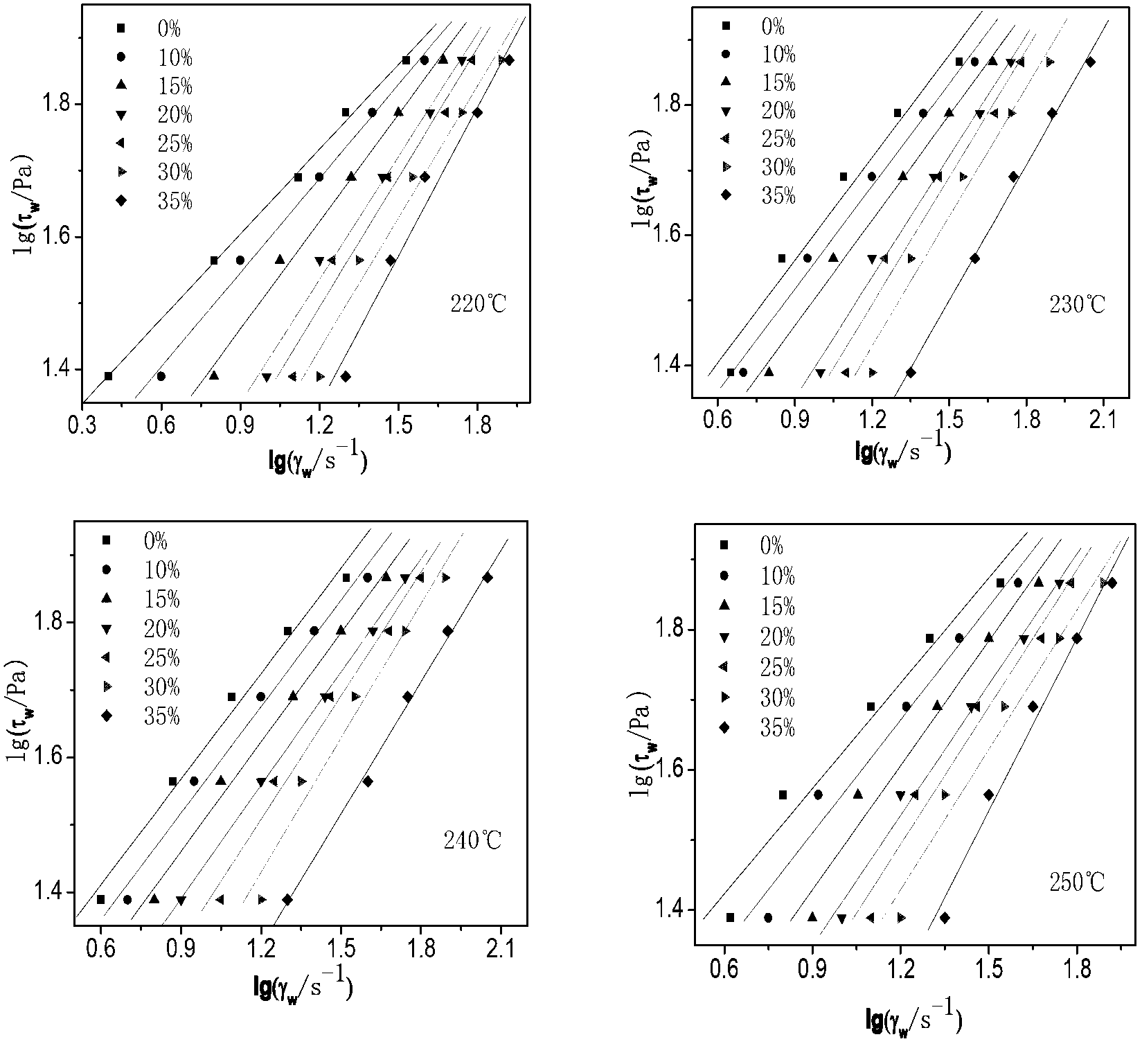

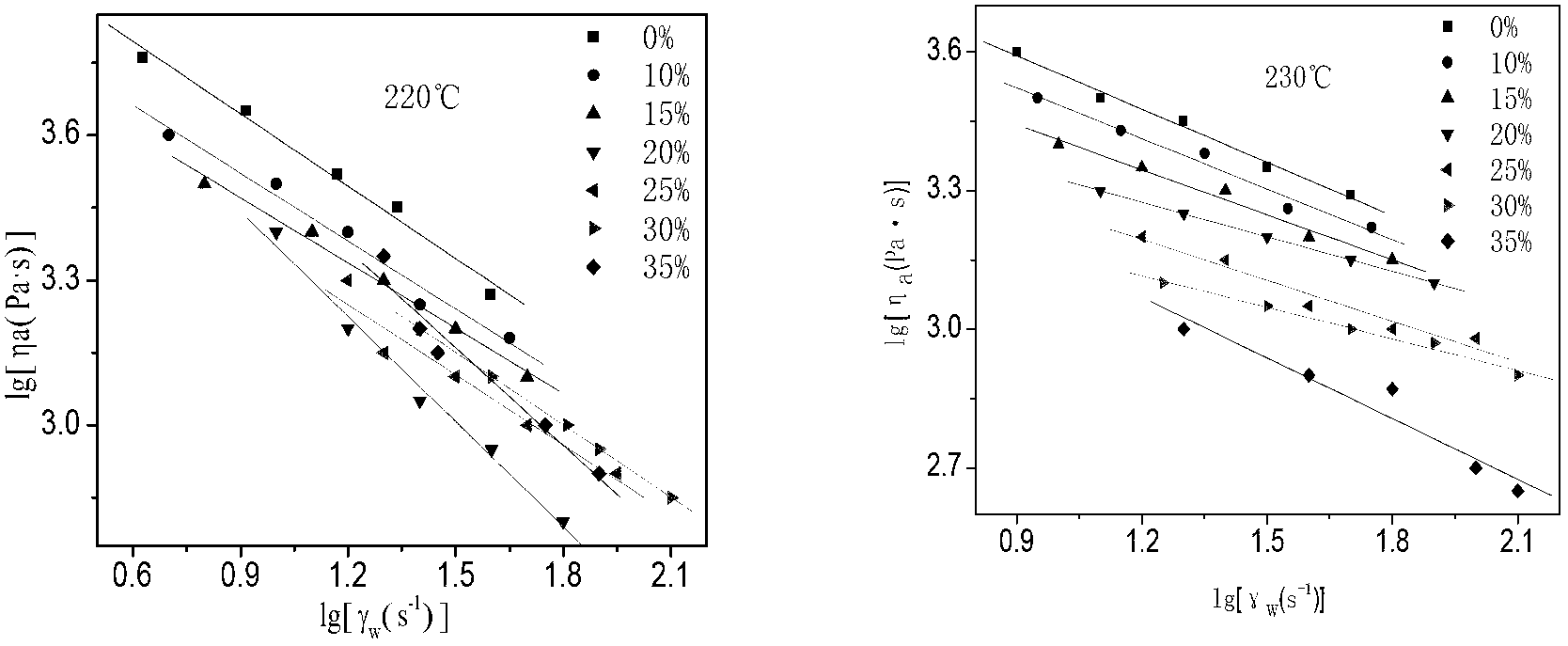

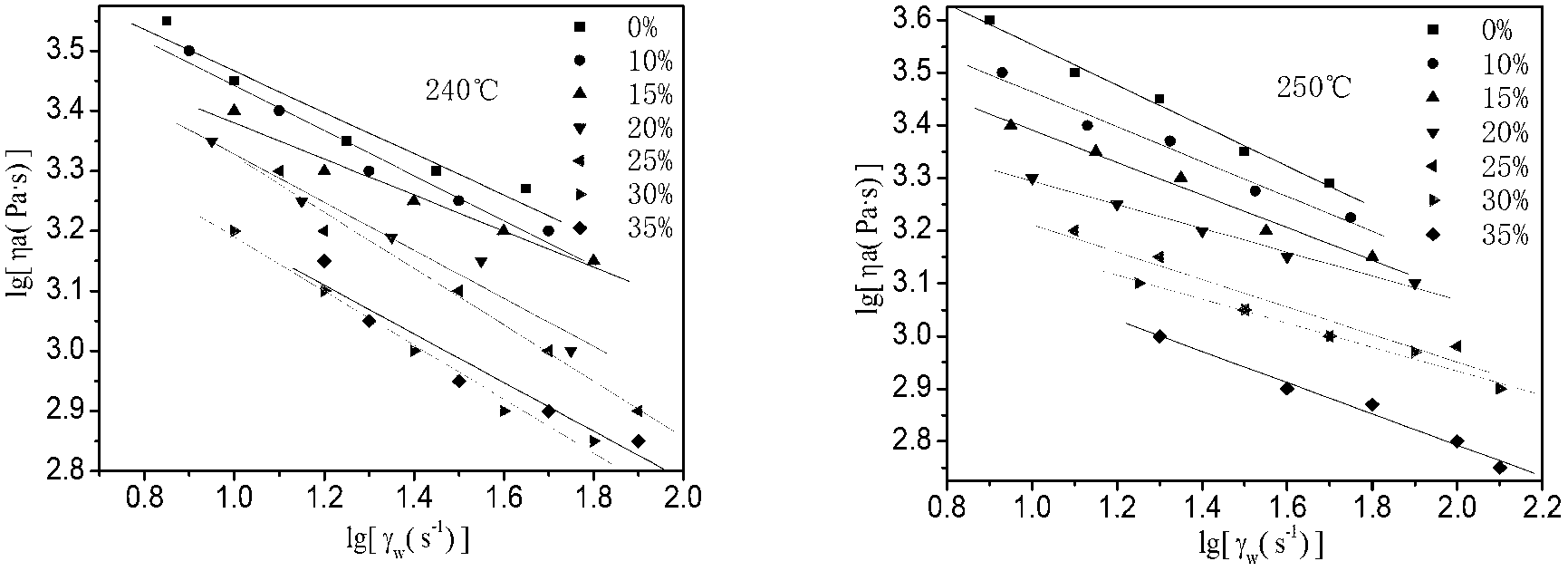

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0019] Glass beads are glass (or ceramic) spheres with a diameter ranging from a few microns to several millimeters. There are solid, hollow, and porous glass beads. They have good optical properties, spherical lens characteristics, strong impact resistance, and rolling. Good thermal conductivity, low thermal conductivity, light weight, etc., have been widely used in urban traffic signs, car license plates, retroreflective curtains, injection technology, filling materials, insulation materials and other fields.

[0020] Glass beads are glass (or ceramic) spheres with a diameter ranging from a few m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com