Preparation method of novel medical hydrogel dressing

A hydrogel medical and hydrogel technology, which is applied in the field of preparation of new hydrogel medical dressings, can solve the problems of high temperature resistance of medical accessories, high requirements for production equipment, poor transparency, etc., and achieve short gelation time and swelling Excellent performance and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

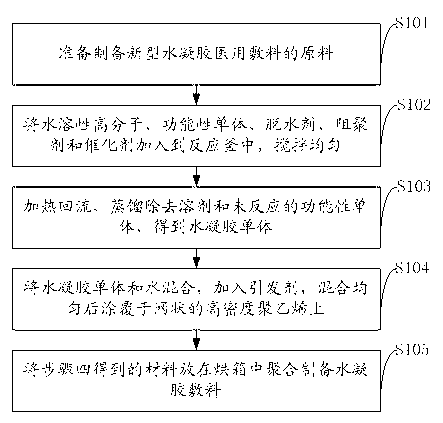

[0031] Such as figure 1 Shown, the preparation method of the novel hydrogel medical dressing that the embodiment of the present invention provides comprises the following steps:

[0032] Step 1, preparing raw materials for preparing novel hydrogel medical dressings;

[0033] Step 2, adding water-soluble polymers, functional monomers, dehydrating agents, polymerization inhibitors and catalysts into the reactor, and stirring evenly;

[0034] Step 3, heating to reflux, distilling off the solvent and unreacted functional monomers to obtain hydrogel monomers;

[0035] Step 4, mixing the hydrogel monomer with water, adding an initiator, mixing evenly, and coating on the reticular high-density polyethylene;

[0036] Step 5, putting the material obtained in Step 4 into an oven to polymerize to prepare a hydrogel dressing.

[0037] As an optimized solution of the embodiment of the present invention, the novel hydrogel medical dressing comprises the following components as raw materi...

Embodiment 1

[0057] Hydrogel medical dressing, comprising the following components:

[0058] Water-soluble polymer: 20 g of polyethylene glycol; functional monomer: 4 g of acrylic acid; dehydrating agent: 40 g of toluene; polymerization inhibitor: 0.1 g of p-cresol; catalyst: 1.5 g of p-toluenesulfonic acid.

[0059] The preparation method of hydrogel medical dressing, comprises the following steps:

[0060] Step 1, add polyethylene glycol, acrylic acid, toluene, p-cresol and p-toluenesulfonic acid into the reaction kettle, stir evenly, heat to a temperature range of 120 °C, and the reaction time is 3 h, then distill off the solvent and unreacted acrylic acid to obtain hydrogel monomer;

[0061] Step 2, mix the hydrogel monomer with water (3 times the weight of the hydrogel monomer), add the initiator azobisisobutyronitrile (0.5% by weight of the hydrogel monomer), mix well and coat Put it on the mesh material and put it in an oven at 40°C for 1 h to obtain a transparent cross-linked compo...

Embodiment 2

[0064] The dosage of each component of the hydrogel dressing described in this embodiment is as follows:

[0065] Water-soluble polymer: polyethylene glycol 40 g; functional monomer: methacrylic acid 20 g; dehydrating agent: xylene 80 g; polymerization inhibitor: p-cresol, hydroquinone, 0.05 g each; catalyst: p-toluenesulfonic acid 1 g.

[0066] The preparation method of the hydrogel dressing described in the present embodiment comprises the following steps:

[0067] Step 1: Add polyethylene glycol, methacrylic acid, xylene, p-cresol / hydroquinone and p-toluenesulfonic acid into the reaction kettle, stir evenly, heat to 80°C, reflux for 6 h, and then distill Remove solvent and unreacted methacrylic acid to obtain hydrogel;

[0068] Step 2, mixing the hydrogel monomer with water (1.5 times the weight of the hydrogel monomer), adding ammonium persulfate / tetramethylethylenediamine (in equal proportions, the total weight is 0.7 times the weight of the hydrogel monomer) %), mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com