Method for separating and purifying capsaicin and paprika red pigment through molecular distillation

A technology of capsanthin and molecular distillation, which is applied in chemical instruments and methods, alkaloids, alkaloids, etc., can solve the problem that silica gel column chromatography consumes a large amount of mobile phase, it is difficult to achieve large-scale industrial production, and it is difficult to obtain high Purity products and other issues, to achieve good market prospects, white crystal color, to maintain the effect of naturalness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] S0. Grind the dried fruits or pericarp of Guizhou Dafang pepper through a 60-mesh sieve, weigh 500g, add 4000ml of acetone at 65°C for heat reflux extraction for 3 hours, repeat the extraction 3 times, filter, combine the extracts and concentrate under reduced pressure to become pepper Oleoresin;

[0043] S1. Mix the obtained capsicum oleoresin and glycerin according to the ratio of 1:3 (v / v) evenly, the vacuum degree is 2000Pa, the distillation temperature is 90°C, the material flow rate is 3ml / min, the speed of the scraping film is 300rpm, and the condensation surface temperature At 25°C, molecular distillation removes residual acetone;

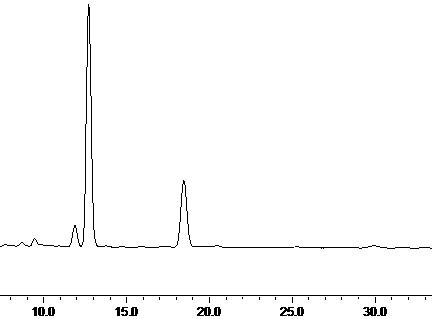

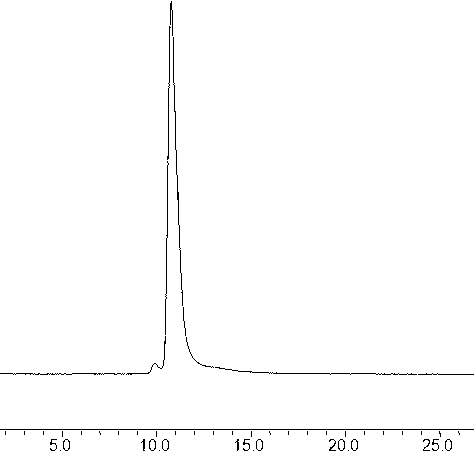

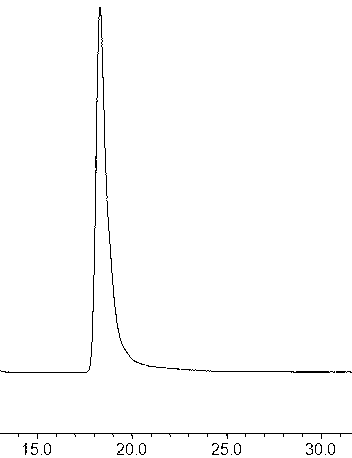

[0044] S2. The material after removing acetone is subjected to molecular distillation at a vacuum of 1Pa, a distillation temperature of 150°C, a material flow rate of 1.5ml / min, a wiper rotation speed of 350rpm, and a condensation surface temperature of 23°C to obtain capsaicin-like substances And capsanthin, the national standard G...

Embodiment 2

[0049] S0. Grind the dried fruit or pericarp of Guizhou Bijiexianjiao through a 40-mesh sieve, weigh 500g, add 4000ml of 95% ethanol and carry out heat reflux extraction at 65°C for 3 hours, repeat the extraction twice, filter, and combine the extracts to reduce Concentrate into capsicum oleoresin under pressure;

[0050] S1. Mix the obtained capsicum oleoresin and glycerin according to the ratio of 1:4 (v / v) evenly, the vacuum degree is 1500Pa, the distillation temperature is 95°C, the material flow rate is 4ml / min, the speed of the scraping film is 350rpm, and the condensation surface temperature At 25°C, molecular distillation removes residual ethanol;

[0051] S2. The material after removing ethanol is subjected to molecular distillation at a vacuum of 0.5Pa, a distillation temperature of 150°C, a material flow rate of 1.5ml / min, a wiper rotation speed of 400rpm, and a condensation surface temperature of 20°C to obtain capsaicin. Substances and capsanthin, the color value...

Embodiment 3

[0056] S1. Crush the dried fruit or pericarp of Vietnamese pepper through a 50-mesh sieve, weigh 500g, add 4000ml of 95% ethanol at 65°C for heat reflux extraction for 3 hours, repeat the extraction twice, filter, and combine the extracts to concentrate under reduced pressure Capsicum oleoresin;

[0057] S2. Mix the obtained capsicum oleoresin and camellia oil in a ratio of 1:2 (v / v) evenly, at a vacuum degree of 1500Pa, at a distillation temperature of 90°C, at a material flow rate of 3ml / min, at a speed of 300rpm for the scraping film, on the condensation surface At a temperature of 25°C, molecular distillation removes residual ethanol;

[0058] S3. Molecular distillation of the material after removing ethanol is carried out under the conditions of vacuum degree of 1Pa, distillation temperature of 150°C, material flow rate of 1.5ml / min, scraping film rotation speed of 400rpm, and condensation surface temperature of 23°C to obtain capsaicin-like substances And capsanthin, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com