Coal-based electric power and chemical product coproduction process capable of realizing zero discharge of CO2

A zero-emission, chemical technology, used in the preparation of hydroxyl compounds, the preparation of carboxylic acids by carbon monoxide reaction, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

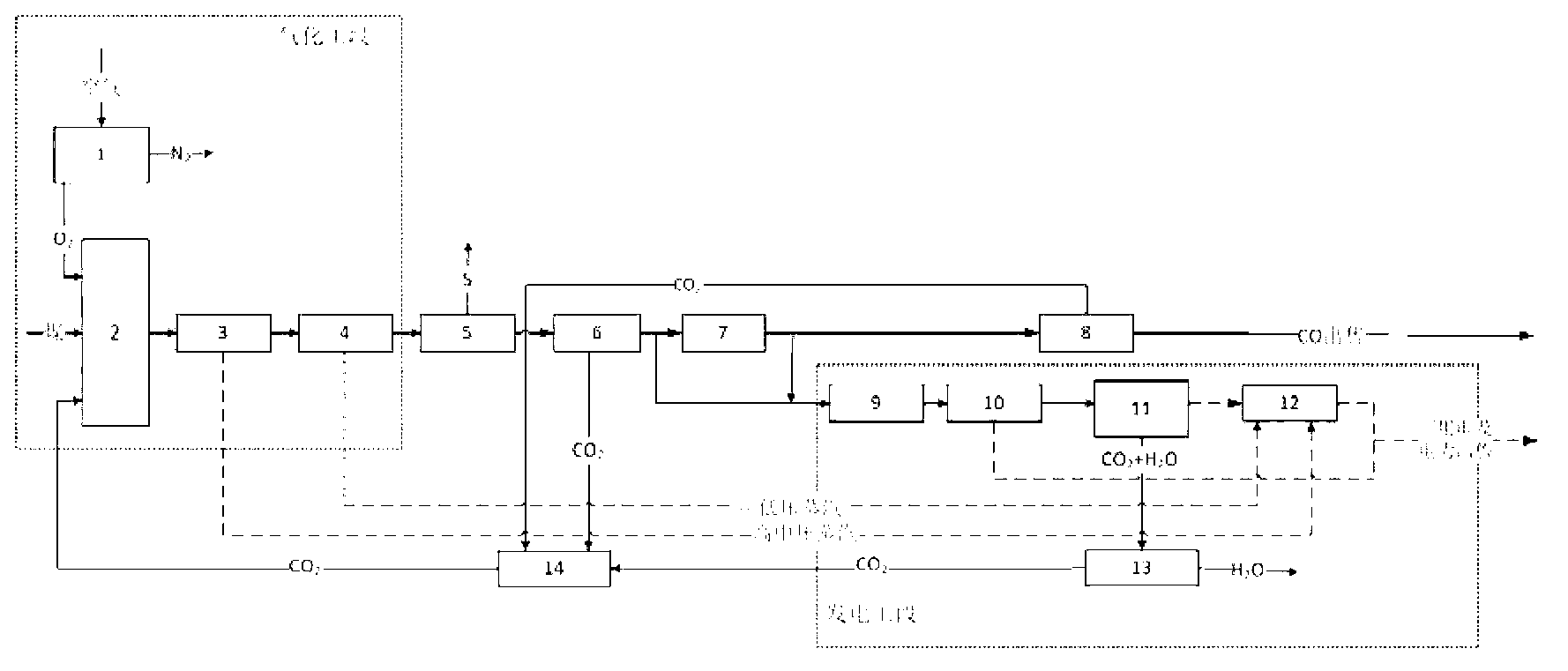

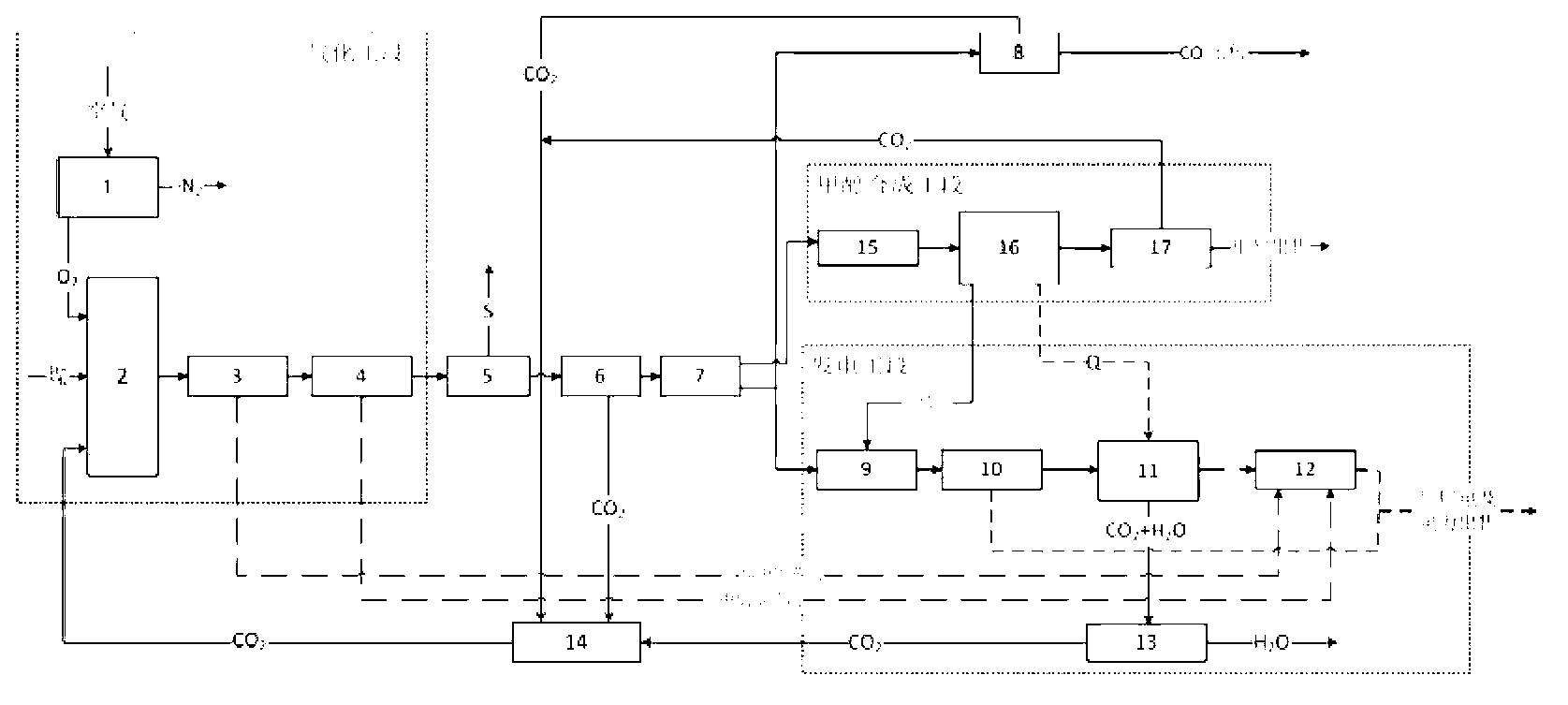

Image

Examples

Embodiment 1

[0052] Taking Dazhuang Coal as an example, the gasification unit uses CO 2 instead of H 2 O is used as a gasification agent to carry out coal gasification reaction at 1200-1600 ° C and 0.1-10 MP pressure. Dazhuang coal is one of the common coal types, with high carbon content and low hydrogen content. The elemental analysis of Dazhuang coal is as follows:

[0053] the element

C

H

N

S

O

Content (%)

72.4

3.4

1.4

0.9

3.1

[0054] Assuming that the coal processing capacity is 600,000 tons / year (based on 8,000 working hours per year, the processing capacity per hour is 75t / hr), the working condition data in the gasifier are as follows:

[0055] Operating data table

[0056]

[0057] Keeping the amount of coal processed, the oxygen-to-coal ratio constant, and the reaction temperature around 1600°C, CO 2 Gradually replace H 2 O (0%, 20%, 40%, 60%, 80%, 100% volume H in the table 2 O is replaced by the correspondin...

Embodiment 2

[0133] Taking Huangxian coal as an example, the gasification unit uses CO 2 instead of H 2 O is used as a gasification agent for coal gasification reaction at 1200-1600°C and 0.1-10MP pressure. Huangxian coal is also a common type of coal, which has low carbon content but high hydrogen and oxygen content. The elemental analysis of Huangxian coal is as follows:

[0134] the element

C

H

N

S

O

Content (%)

68

6.2

1.4

0.5

14.5

[0135] Also assuming that the coal processing capacity is 600,000 tons / year (based on 8,000 working hours per year, the hourly processing capacity is 75 t / hr), the working condition data is the same as that in Example 1.

[0136] Keeping the amount of coal processed, the oxygen-to-coal ratio constant, and the reaction temperature around 1600°C, CO 2 Gradually replace H 2 O, the main components of syngas are as follows:

[0137] Huangxian coal gasification using CO under the condition of fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com