Puffed wheat nursery pig feed and preparation method thereof

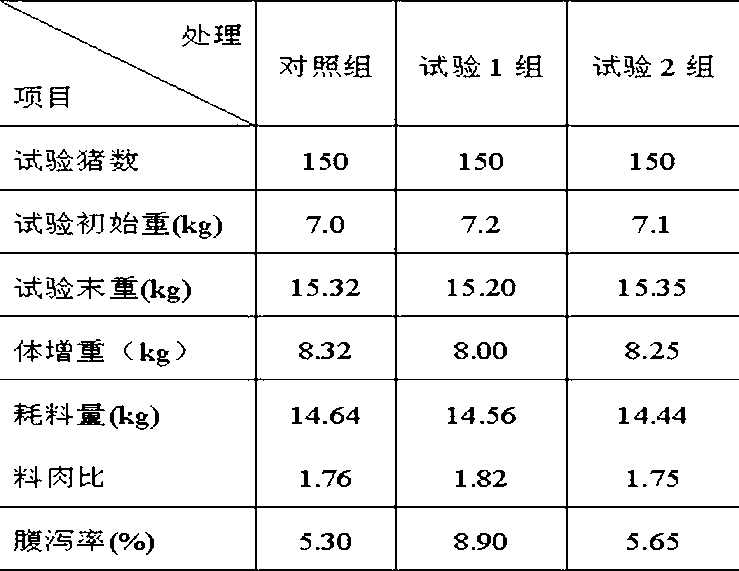

A technology of puffed wheat and nursery pigs, which is applied in the field of feed for nursery pigs and its processing, can solve the problems of uneven heating of wheat, low energy utilization rate, and incomplete ripening, so as to improve efficiency and influence, improve digestion and absorption, and reduce Effect of Diarrhea Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Get main raw material by following weight parts:

[0024] 78 parts of puffed wheat, 14 parts of high-protein puffed soybean meal, 3 parts of imported fish meal, 1 part of first-grade soybean oil, 4 parts of premix;

[0025] Wherein the composition of the premix by weight is: 0.25 parts of compound trace elements, 0.30 parts of multi vitamins, 0.06 parts of sweetener, 0.65 parts of amino acid compound, 0.05 part of phytase, 0.02 part of wheat compound enzyme, 0.1 part of probiotic preparation, 0.30 part of table salt, 0.50 part of calcium hydrogen phosphate, 0.40 part of stone powder, and the balance is carrier, and the carrier is fermented soybean meal and rice bran.

[0026] The specific content of compound trace elements in the premix is: copper 3000mg / kg, iron 4000mg / kg, manganese 1000mg / kg and zinc 1200mg / kg;

[0027] The specific content of multivitamins in the premix is: vitamin K3 5mg / kg, vitamin B2 8mg / kg, vitamin B6 2mg / kg, vitamin A 30000IU / kg, vitamin D3 500...

Embodiment 2

[0037] Get main raw material by following weight parts:

[0038] 78 parts of puffed wheat, 14 parts of high-protein puffed soybean meal, 3 parts of imported fish meal, 1 part of first-grade soybean oil, 4 parts of premix;

[0039] Wherein the composition by weight of the premix is: 0.30 parts of compound trace elements, 0.70 parts of multivitamins, 0.10 parts of sweeteners, 0.89 parts of amino acid complexes, 0.05 parts of phytase, 0.02 parts of wheat compound enzymes, 0.1 parts of probiotic preparations, 0.35 part of table salt, 0.82 part of hydrogen phosphate, 0.80 part of stone powder, and the balance is carrier, and the carrier is fermented soybean meal and rice bran.

[0040] The specific content of compound trace elements in the premix is: copper 5000mg / kg, iron 6250mg / kg, manganese 3500mg / kg and zinc 3750mg / kg;

[0041] The specific content of multivitamins in the premix is: vitamin K3 60mg / kg, vitamin B2 8mg / kg, vitamin B6 2mg / kg, vitamin A 45000IU / kg, vitamin D3 1200...

Embodiment 3

[0051] Get main raw material by following weight parts:

[0052] 78 parts of puffed wheat, 14 parts of high-protein puffed soybean meal, 3 parts of imported fish meal, 1 part of first-grade soybean oil, 4 parts of premix;

[0053] Wherein the composition of the premix by weight is: 0.28 parts of compound trace elements, 0.50 parts of multivitamins, 0.08 parts of sweeteners, 0.77 parts of amino acid complexes, 0.05 parts of phytase, 0.02 parts of wheat compound enzymes, 0.1 parts of probiotic preparations, 0.33 parts of table salt, 0.65 parts of calcium hydrogen phosphate, 0.55 parts of stone powder, and the rest are carriers, and the carriers are fermented soybean meal and rice bran.

[0054] The specific content of compound trace elements in the premix is: copper 4000mg / kg, iron 5000mg / kg, manganese 2250mg / kg and zinc 2500mg / kg;

[0055] The specific content of multivitamins in the premix is: vitamin K3 35mg / kg, vitamin B2 8mg / kg, vitamin B6 2mg / kg, vitamin A 40000IU / kg, vit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com