Catalyst component and method for removing sulfur oxides and nitric oxides from smoke

A nitrogen oxide and sulfur oxide technology is applied in the field of flue gas purification, which can solve the problems of high energy consumption and complex process, and achieve the effects of low operating cost, simple process and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

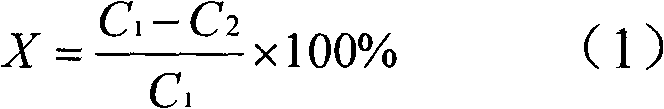

[0046] A total of 200 g of catalysts were loaded into the moving bed reactor, wherein spent FCC catalyst accounted for 35% by weight, auxiliary catalyst accounted for 5% by weight, activated carbon accounted for 40% by weight, and calcium oxide accounted for 20% by weight. Under the Ar flow, the temperature was raised to 400°C, the Ar gas was stopped, and NO, O 2 , Ar mixed gas, SO in the mixed gas 2 The concentration is 2500mg / m 3 , NO concentration is 1250mg / m 3 , O 2 The concentration is 3.7% (v), the rest is Ar, and the air velocity of the mixed gas is 5500h -1 , using a multifunctional flue gas analyzer to analyze the content of sulfur oxides and nitrogen oxides in the gas after the reaction, and calculate the removal efficiency of sulfur oxides and nitrogen oxides according to formula (1) to be 82.4% and 72.6% respectively.

Embodiment 2

[0048] By the method for embodiment 1, add the FCC waste catalyst of same quality, same ratio, auxiliary catalyst, gac and calcium oxide, under the same space velocity, pass into the mixed gas that forms identical, reaction temperature is raised to 500 ℃, according to ( 1) The efficiency of removing sulfur oxides and nitrogen oxides calculated by formula is 84.6% and 83.5% respectively.

Embodiment 3

[0050] By the method for embodiment 1, add the same quality, the FCC waste catalyst of identical ratio, auxiliary catalyst, gac and calcium oxide, under the same space velocity, pass into the mixed gas that forms identical, reaction temperature is raised to 580 ℃, according to ( 1) The efficiencies of removing sulfur oxides and nitrogen oxides calculated by the formula are 87.3% and 85.7% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com