Waste water biological treatment technology and biological treatment system using same

A biological treatment and waste water technology, applied in the direction of water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. Large amount of discomfort, complex operation management and other problems, to achieve the effect of increasing effective microbial concentration, saving dosage, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

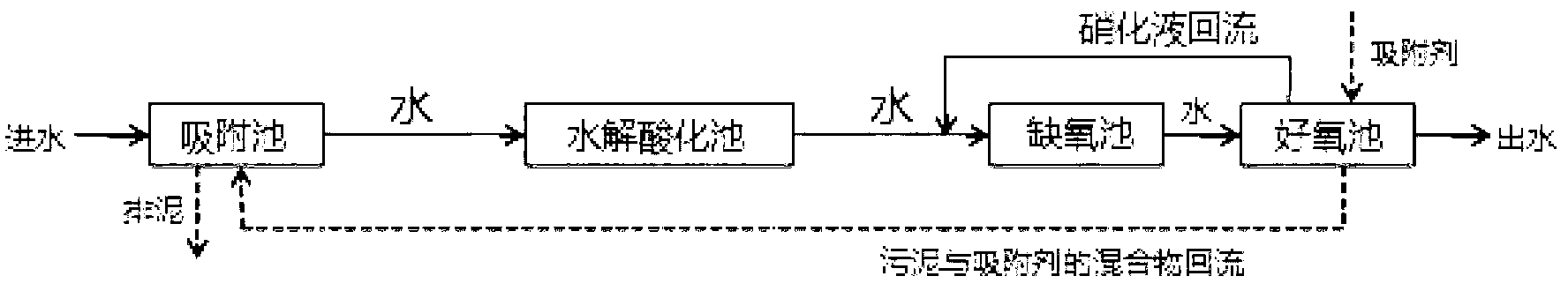

Embodiment 1

[0034] Such as figure 1 Shown is a flow chart of a specific implementation of the industrial wastewater biological treatment system of the present invention. (1) The industrial wastewater first passes through the adsorption tank to remove large molecules in the wastewater that are difficult to degrade organics and toxic substances, reducing the impact on the subsequent biochemical system In addition to toxicity inhibition, the adsorbent used is a mixture of excess sludge returned from the aerobic tank and activated coke. (2) The wastewater after adsorption treatment enters the biochemical system. In this embodiment, the wastewater passes through a hydrolysis acidification tank, an anoxic tank, and an aerobic tank for biological treatment. Add activated coke to the aerobic tank to strengthen the degradation performance of aerobic microorganisms on the organics in the wastewater, and ensure the stable and up-to-standard discharge of the effluent. The mass concentration of the adso...

Embodiment 2

[0037] The process flow of this embodiment is the same as figure 1 The process flow shown is the same. (1) The industrial waste water first passes through the adsorption tank to remove the large molecules in the waste water that are difficult to degrade organics and toxic substances, reducing the impact on the subsequent biochemical system and toxicity inhibition. The adsorbent used is an aerobic tank Mixture of recirculated surplus sludge and activated coke. (2) The wastewater after adsorption treatment enters the biochemical system. In this embodiment, the wastewater passes through the hydrolysis acidification tank, the anoxic tank, and the aerobic tank for biological treatment. The activated coke is added to the aerobic tank to strengthen The degradation performance of the aerobic microorganisms on the organic matter in the wastewater ensures the stable discharge of the effluent water quality. The mass concentration of the adsorbent in the aerobic tank is 50mg / L (that is, the...

Embodiment 3

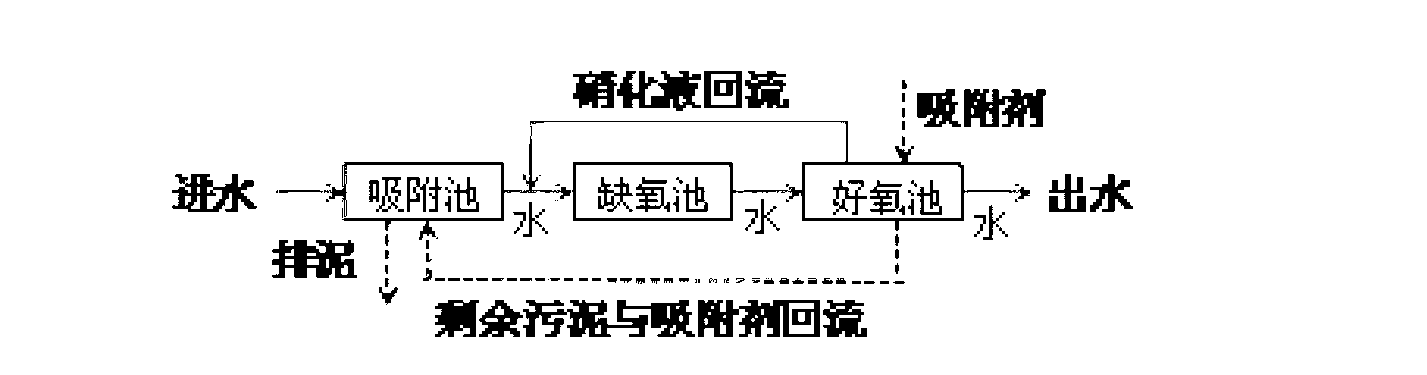

[0040] Such as figure 2 As shown, (1) The industrial wastewater first passes through the adsorption tank to remove the large molecules in the wastewater that are difficult to degrade organics and toxic substances, reducing the impact on the subsequent biochemical system and toxicity inhibition. The adsorbent used is the remaining sewage returned from the aerobic tank. A mixture of mud and lignite. (2) The wastewater after adsorption treatment enters the AO system, that is, the wastewater passes through an anoxic tank and an aerobic tank for biological treatment. Add lignite to the aerobic tank to strengthen the degradation performance of aerobic microorganisms on the organics in the wastewater, and ensure the stable and up-to-standard discharge of the effluent. The mass concentration of the adsorbent in the aerobic tank is 2000mg / L (that is equivalent to the wastewater in the aerobic tank The mass ratio to adsorbent is 500:1). The nitrification liquid in the aerobic tank is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com