Escherichia coli engineered strain and application in succinic acid production through aerobic-microaerobic-anaerobic full-stage fermentation of Escherichia coli engineered strain

A technology of Escherichia coli and engineering strains, which is applied in the fields of metabolic engineering and microbial fermentation, and can solve the problems of long fermentation period, slow growth of Escherichia coli, and low carbon source conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

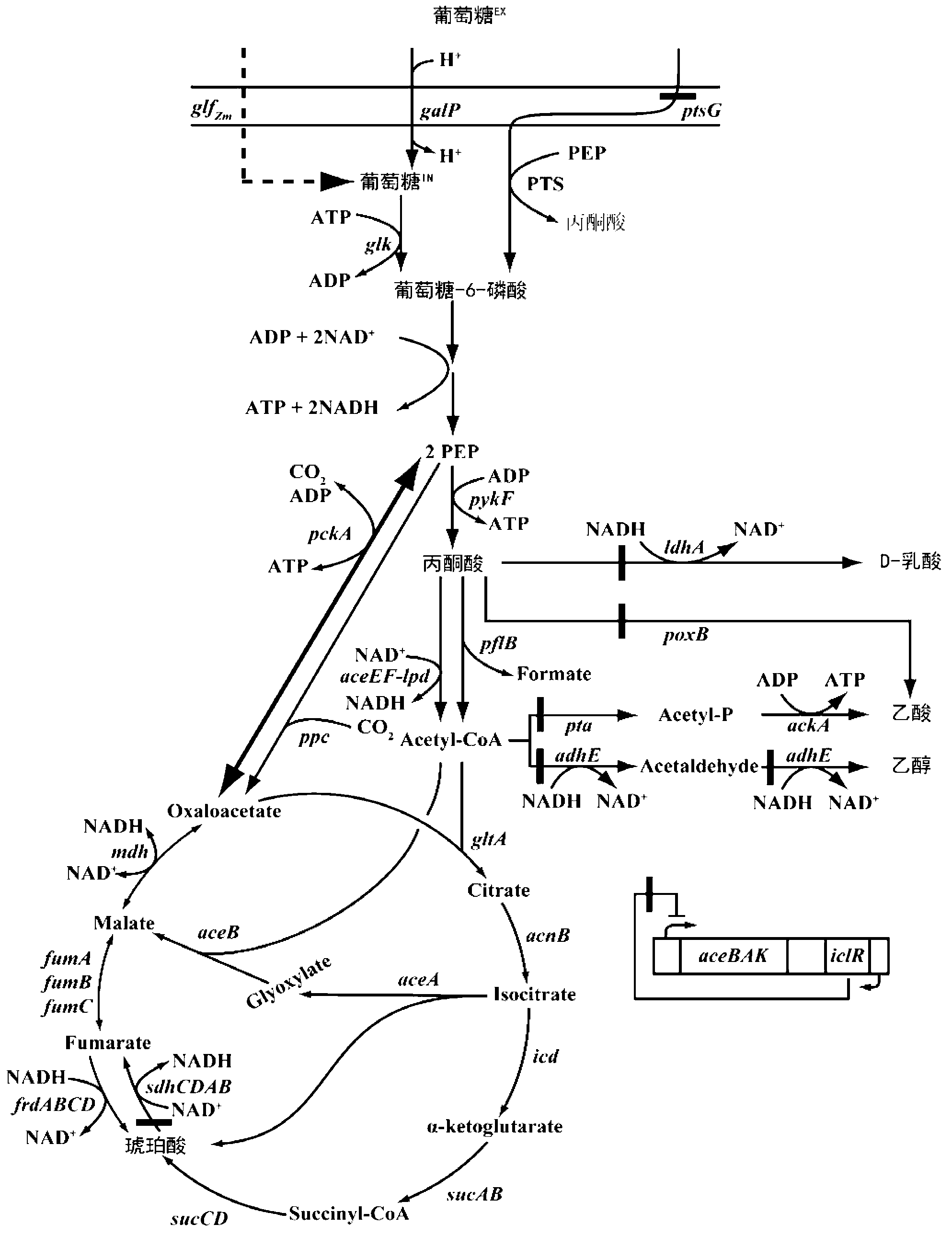

Method used

Image

Examples

Embodiment 1

[0066] The construction of embodiment 1 engineering strain

[0067] (1). Knockout of ptsG gene:

[0068] Bacteria: Escherichia coli MG1655

[0069] Described LB substratum is: peptone 10g / L, yeast powder 5g / L, NaCl10g / L, ampicillin 100mg / L, chloramphenicol 50mg / L.

[0070] The ampicillin-resistant plate is an LB solid medium containing 100 mg / L ampicillin and 1.5% agar powder.

[0071] The chloramphenicol-resistant plate is the LB solid medium containing 50 mg / L chloramphenicol and 1.5% agar powder.

[0072] The SOB medium is: peptone 2g / L, yeast powder 0.5g / L, NaCl0.0585g / L, KCl0.0186g / L, MgCl 2 0.203g / L.

[0073] a Cloning of homologous recombination fragments

[0074] The target gene was knocked out using the Red recombination system. According to the sequence number of the genome published by Genbank,

[0075] NC_000913.2 Escherichia coli MG1655 ptsG gene sequence with gene ID 945651 and the plasmid pKD3 sequence with GenBank ID AY048742.1 designed primers:

[0076...

Embodiment 2

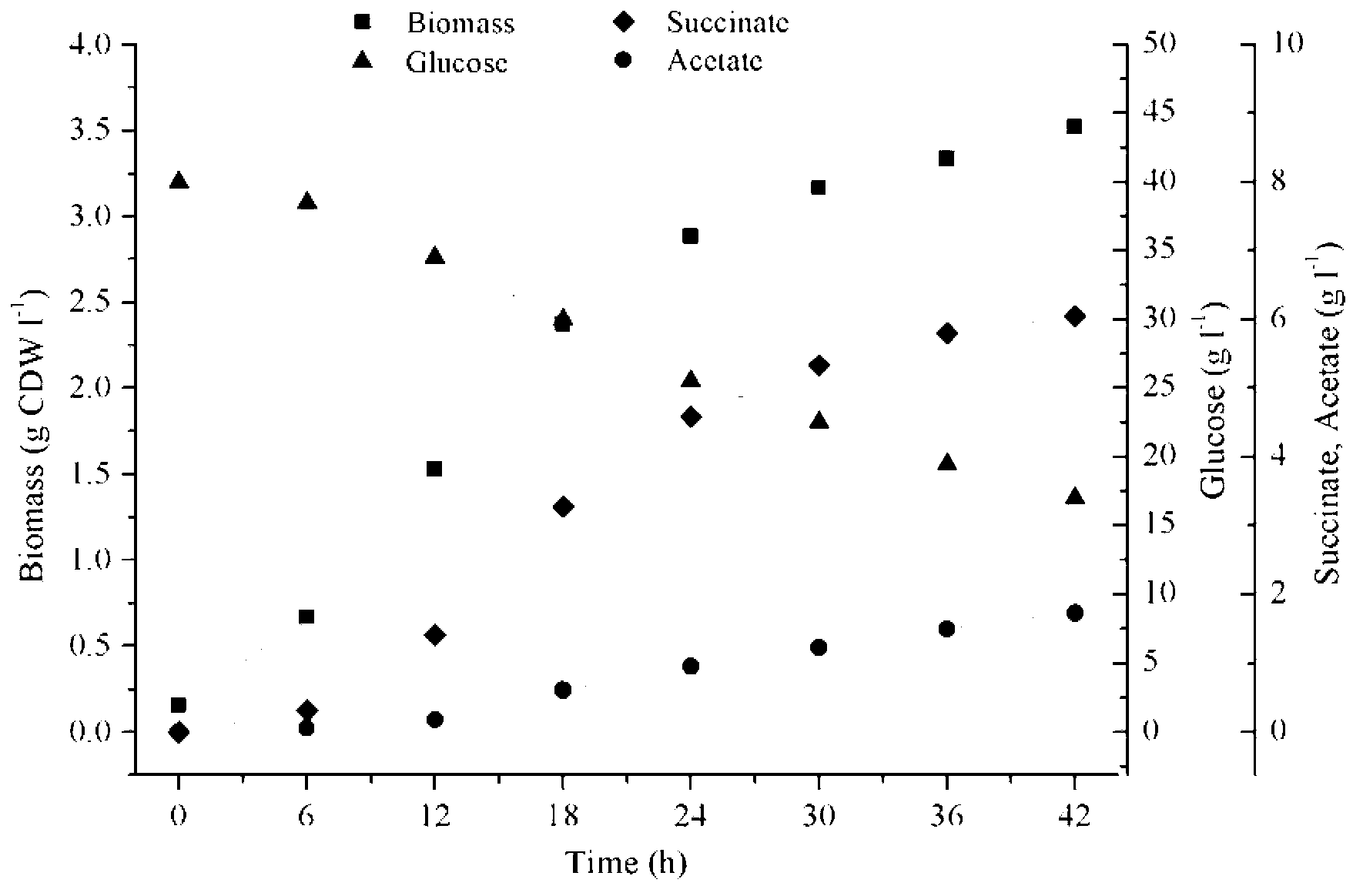

[0398] Example 2. Engineering strain E.coli QZ1111 produces succinic acid under aerobic conditions

[0399] We carried out aerobic succinic acid fermentation of engineering strain E.coli QZ1111 in inorganic salt medium with glucose as the sole carbon source.

[0400] Strain: E.coli QZ1111 [The strain genotype is: MG1655(ΔptsGΔpoxBΔptaΔiclRΔsdhA)]

[0401] (Note, the unmodified original strain MG1655 does not produce succinic acid)

[0402] Seed medium: LB medium (peptone 10g / L, yeast powder 5g / L, NaCl 10g / L).

[0403] Fermentation medium: AM1 medium (composed of (g / L): (NH 4 ) 2 HPO 4 12H 2 O, 2.63; NH 4 h 2 PO 4 , 0.87; KCl, 0.15; MgSO 4 ·7H 2 O, 0.37; trace elements (1000×: FeCl 3 ·6H 2 O, 2.4; CoCl 2 ·6H 2 O, 0.3; CuCl 2 2H 2 O, 0.15; ZnCl 2 , 0.3; Na 2 MoO 4 ·H 2 O, 0.3; H 3 BO 3 , 0.075; MnCl 2 4H 2 O, 0.5; HCl, 120mM); the balance is water).

[0404] Culture method: pick the single clone in the plate into a 300ml Erlenmeyer flask containing 50ml ...

Embodiment 3

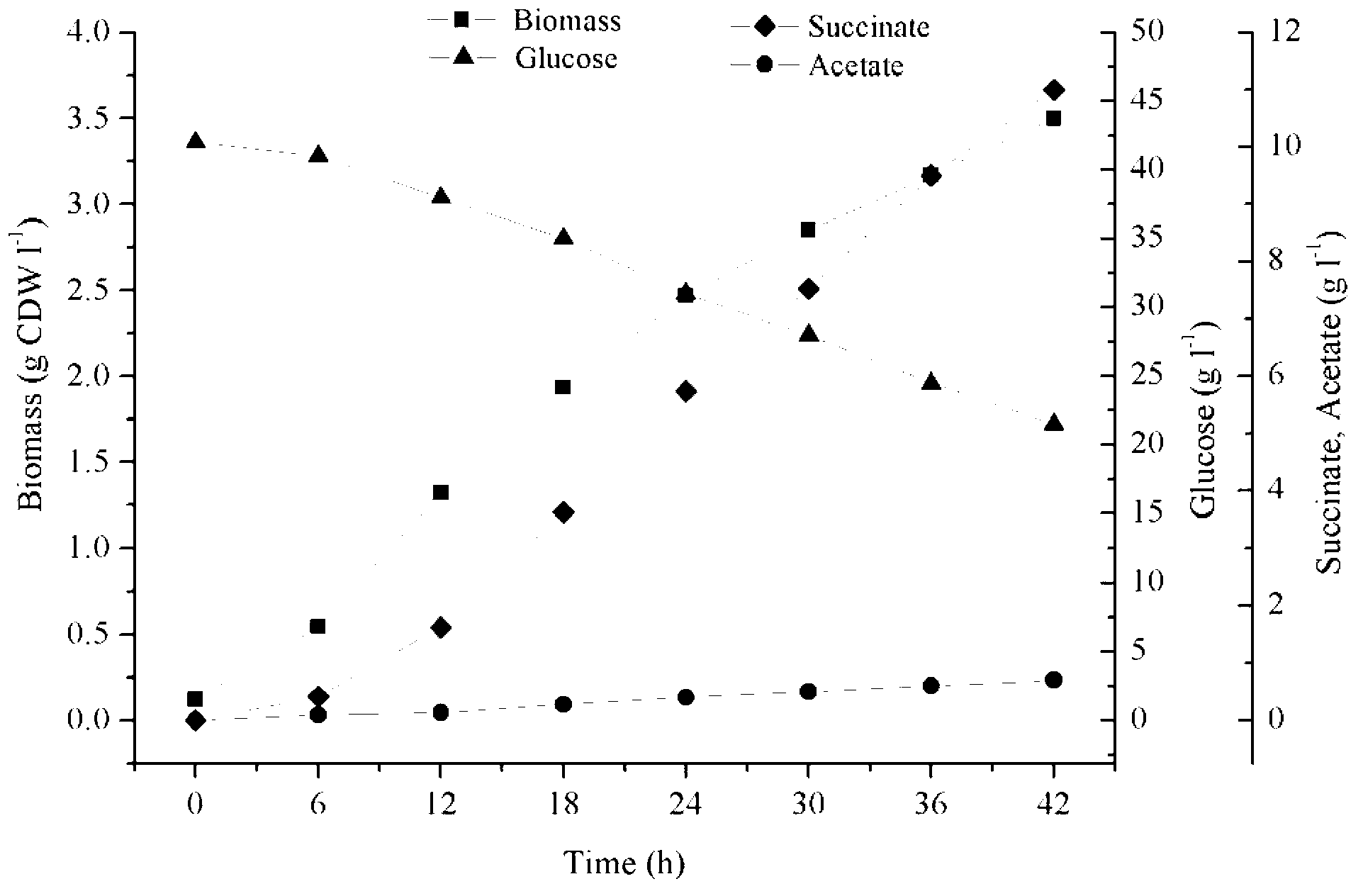

[0407] Example 3. Engineering strain E.coli QMJ03 produces succinic acid under aerobic-microaerobic conditions

[0408] We carried out aerobic-microaerobic two-stage succinic acid fermentation on engineering strain E.coli QMJ03 in inorganic salt medium with glucose as the sole carbon source.

[0409] Strain: E.coli QZ1111 [The strain genotype is: MG1655(ΔptsGΔpoxBΔptaΔiclRΔsdhA)]

[0410] E.coli QMJ03[The strain genotype is: MG1655(ΔptsGΔpoxBΔptaΔiclRΔsdhAΔarcA)]

[0411] Seed medium: LB medium (peptone 10g / L, yeast powder 5g / L, NaCl 10g / L).

[0412] Fermentation medium: AM1 medium (same as above).

[0413] Culture method: pick the single clone in the plate into a 300ml Erlenmeyer flask containing 50ml LB medium. Place them at 37°C for 12 hours, then transfer 5% of the inoculum into a 500ml Erlenmeyer flask containing 80ml of LB medium supplemented with 40g / L glucose, and place them at 37°C for 10 hours at a speed of 250 rpm. Then transfer 10% of the inoculum into a 1,200m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com