Enzymatic synthesis of ivabradine midbody and application in the synthesis of ivabradine and addition salts thereof

A synthetic method and enzymatic technology, which can be used in organic chemistry methods, chemical instruments and methods, preparation of organic compounds, etc., and can solve problems such as low yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] Example 1 :3,4-Dimethoxybicyclo[4.2.0]oct-1,3,5-triene-7-carboxylic acid

[0125] 3,4-dimethoxybicyclo[4.2.0]octa-1,3,5-triene-7-carbonitrile (11 g, 58.1 mmol) was suspended in 1N sodium hydroxide solution (70 mL) and The reaction mixture was refluxed (110°C) for 2 hours.

[0126] After returning to ambient temperature, the mixture was acidified with concentrated hydrochloric acid. Precipitation was observed.

[0127] The product was dissolved in 200 mL of dichloromethane, and the aqueous phase was extracted. with MgSO 4 Drying and evaporation gave the title product in 95.9% yield (11.6 g).

Embodiment 2

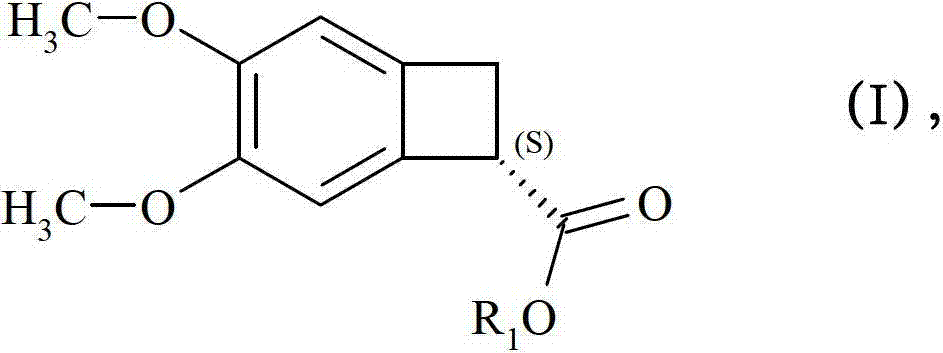

[0128] Example 2 :(7S)-3,4-Dimethoxybicyclo[4.2.0]oct-1,3,5-triene-7-carboxylic acid

[0129] 0.5 g (c=200 g / L) of the racemic acid obtained in Example 1 was dissolved in 2.5 mL of an 8 / 2 mixture of acetonitrile / methanol.

[0130] Then 0.1g (c=40g / L) lipase of Candida antarctica (Candida antarctica) (Novozymes Denmark) was added to the mixture (E / S ratio 1 / 5). The reaction mixture was kept at 30° C. with rotary stirring at 220 rpm for 48 hours.

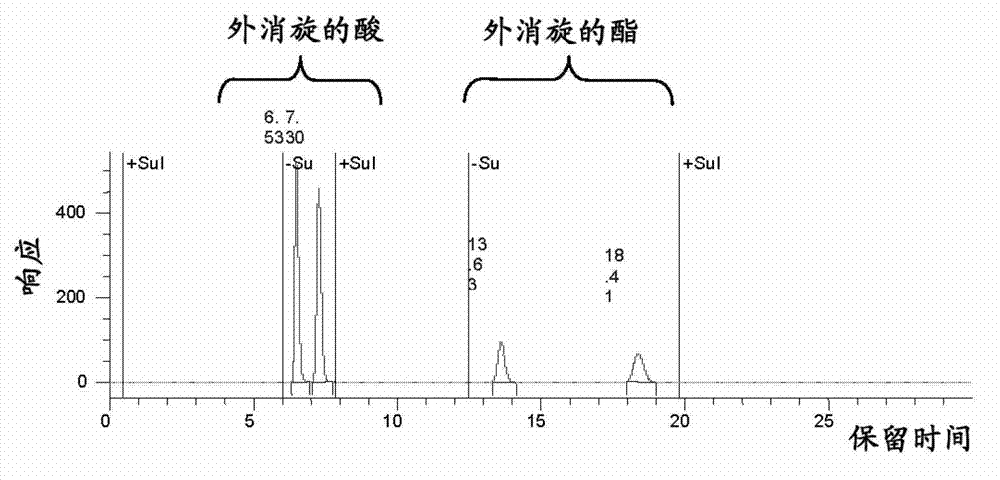

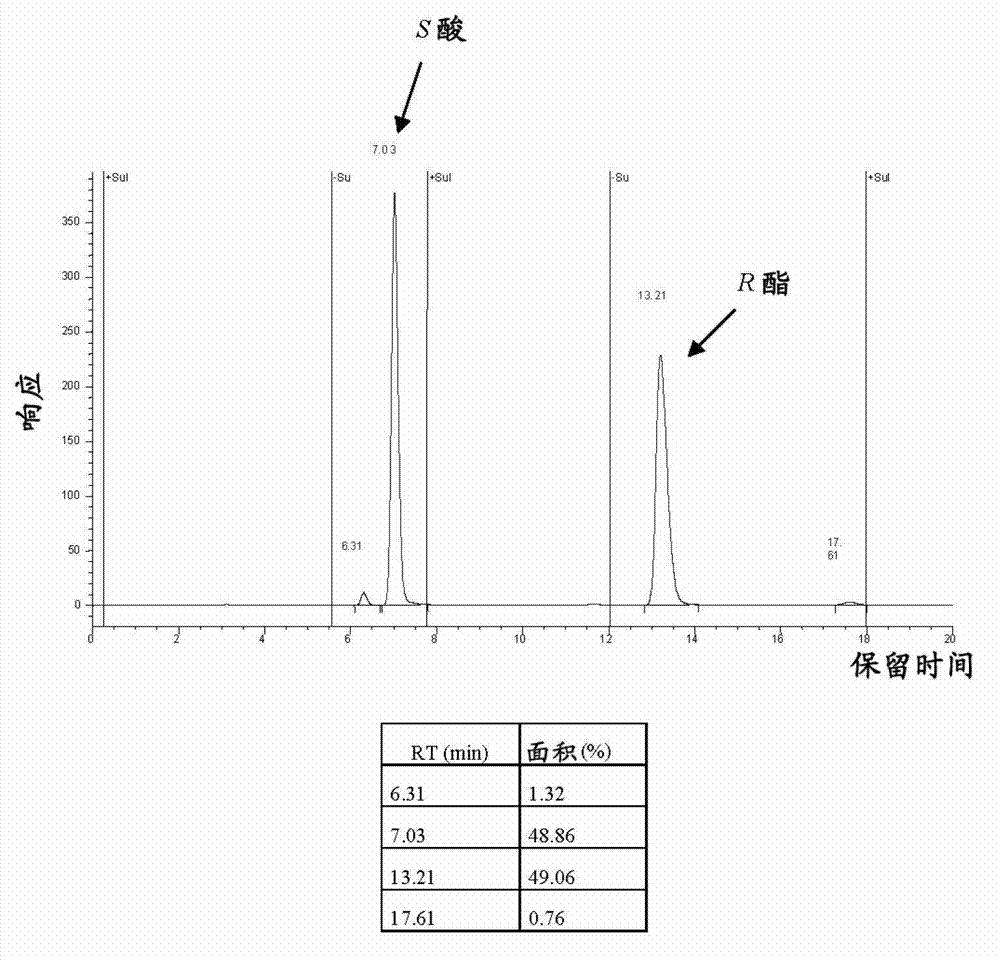

[0131] The reaction was monitored by chiral phase HPLC under conditions enabling the determination of the enantiomeric excess of both the ester and the acid:

[0132] IC250*4.6 column

[0133] 30% anhydrous ethanol + 0.1% TFA + 70% heptane + 0.1% TFA

[0134] 1ml / min, 25°C, 288nm

[0135]

[0136] The chiral phase HPLC chromatograms of the racemic compound and the product after 48 hours are shown in figure 1 and 2 shown.

[0137] After 48 hours, optically pure ester and acid were seen to be provided at an optimal acid...

Embodiment 3

[0141] Example 3 : Methyl 3,4-dimethoxybicyclo[4.2.0]oct-1,3,5-triene-7-carboxylate

[0142] Suspend methyl (7R)-3,4-dimethoxybicyclo[4.2.0]octa-1,3,5-triene-7-carboxylate (445 mg) (ee>96%) in isopropyl Alcohol (2.5 mL), and diazabicycloundecene (58 μl-1.5 eq) was added.

[0143] The reaction mixture was heated at 65°C for 2 hours. Complete racemization was observed at the end of 2 hours of the ester reaction.

[0144] Analysis conditions:

[0145] IC250*4.6 column

[0146] 30% anhydrous ethanol + 0.1% TFA + 70% heptane + 0.1% TFA

[0147] 1ml / min, 25°C288nm

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com