Surface modification method of aramid, and reinforced natural rubber material and preparation method thereof

A surface modification, natural rubber technology, applied in the field of polymer science, can solve the problems of the decrease of the molecular weight of the rubber, the excessive reduction of the fiber length, and the lack of composite materials, and achieve good interface bonding, improved interface bonding strength, Good fiber dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

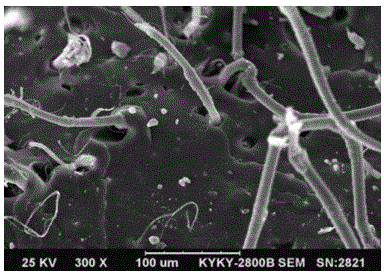

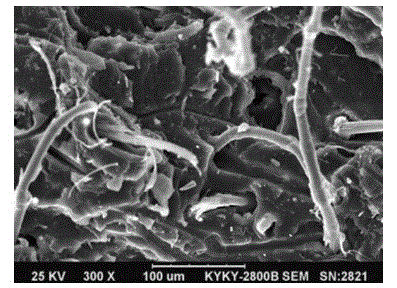

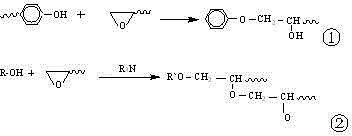

[0020] Example 2 of the present invention: a method for surface modification of aramid fibers, cutting aramid filaments (brand: AF-1000, 1500 denier, Korean ALKEX company) into 20mm sections, ultrasonically cleaning the aramid fibers with acetone for 0.5 hours, and then drying , remove the organic coating attached to its surface; then impregnate the aramid fiber with a phosphoric acid solution with a concentration of 10% by mass at a temperature of 20°C for 3 hours, take it out, wash and dry it, and then use an epoxy resin with a concentration of 20% by mass The acetone solution of resin (bisphenol A type, brand E44) impregnated the aramid fiber at room temperature for 1 hour, and after drying, the surface modification of the aramid fiber was completed, and the modified aramid fiber was obtained for use.

[0021] Modified aramid fiber and vulcanized natural rubber composite material, calculated by weight fraction, including 100 parts of natural rubber (No. 1 standard rubber, Me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com