Chemical cleaning method for immersed membrane element

A submerged membrane and element technology, which is applied in the field of chemical cleaning of submerged membrane elements, can solve the problems of poor recovery and achieve a high recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] The present invention will be specifically described below by referring to Examples and Comparative Examples, but it should be understood that the present invention is not limited to these Examples.

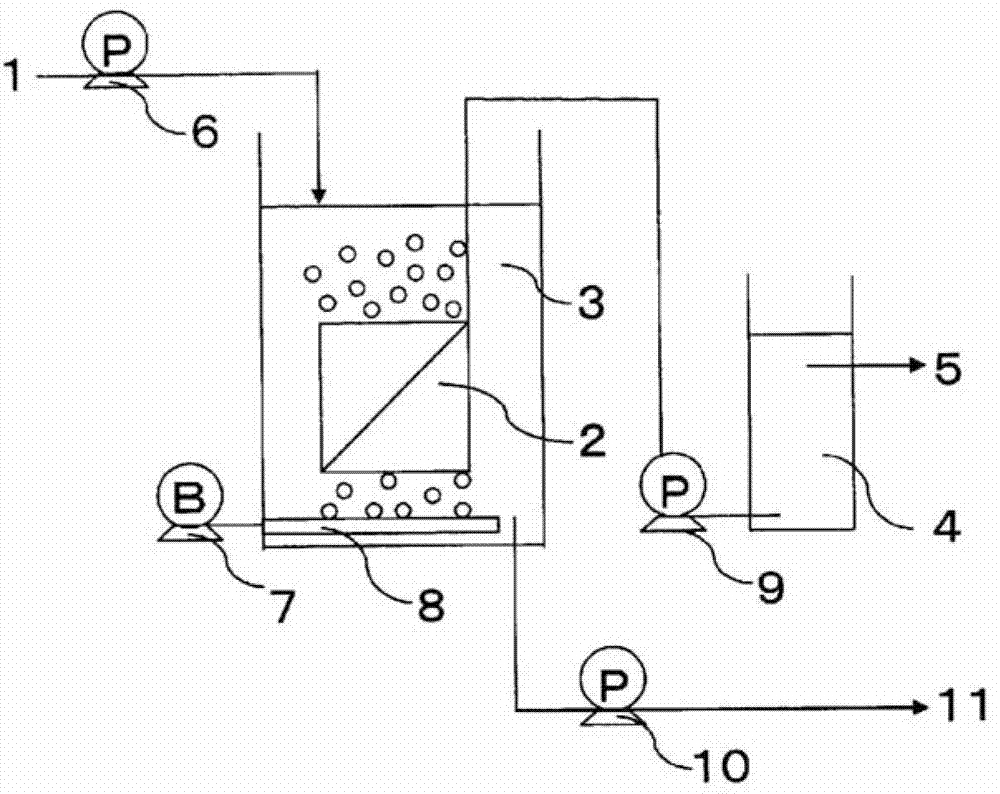

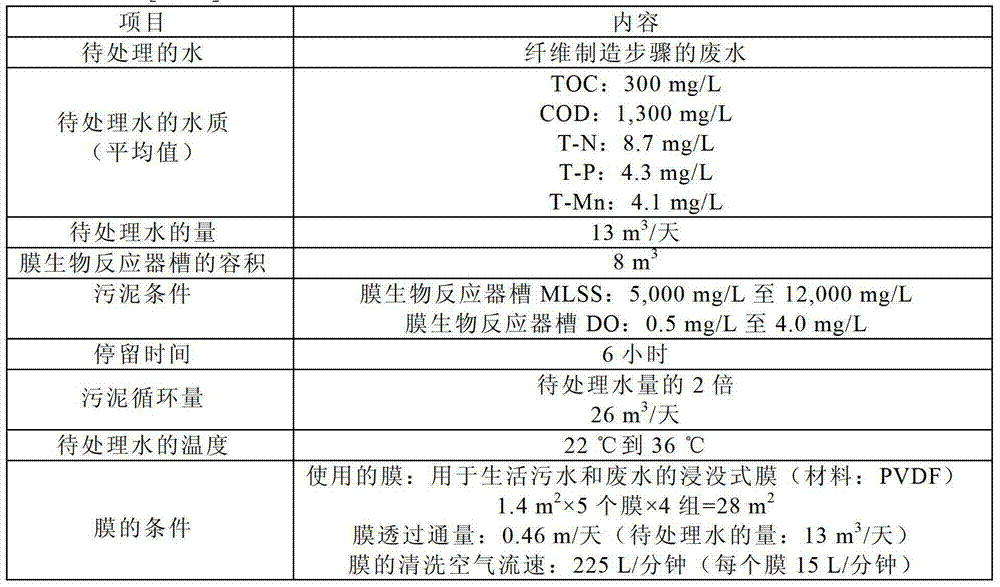

[0064] Waste water from the fiber manufacturing step was used as water to be treated, and after the membrane bioreactor unit was continuously operated for about 3 months, four sets of separation membranes (provided by Toray Industries, Ltd.) in which a decrease in permeation was observed were cleaned in tanks using different cleaning methods. , Inc., submerged membrane for domestic sewage and wastewater, the material is polyvinylidene fluoride, the membrane area is 1.4m 2 ) were cleaned (per group: 1.4m 2 ×5 films). The operating conditions are shown in Table 1. As for the chemical cleaning conditions, four methods shown in Table 2 were performed using sodium hypochlorite (pH 11.7) and sodium hydroxide, and oxalic acid (pH 2.1) and hydrochloric acid. Each chemical was i...

Embodiment 1)

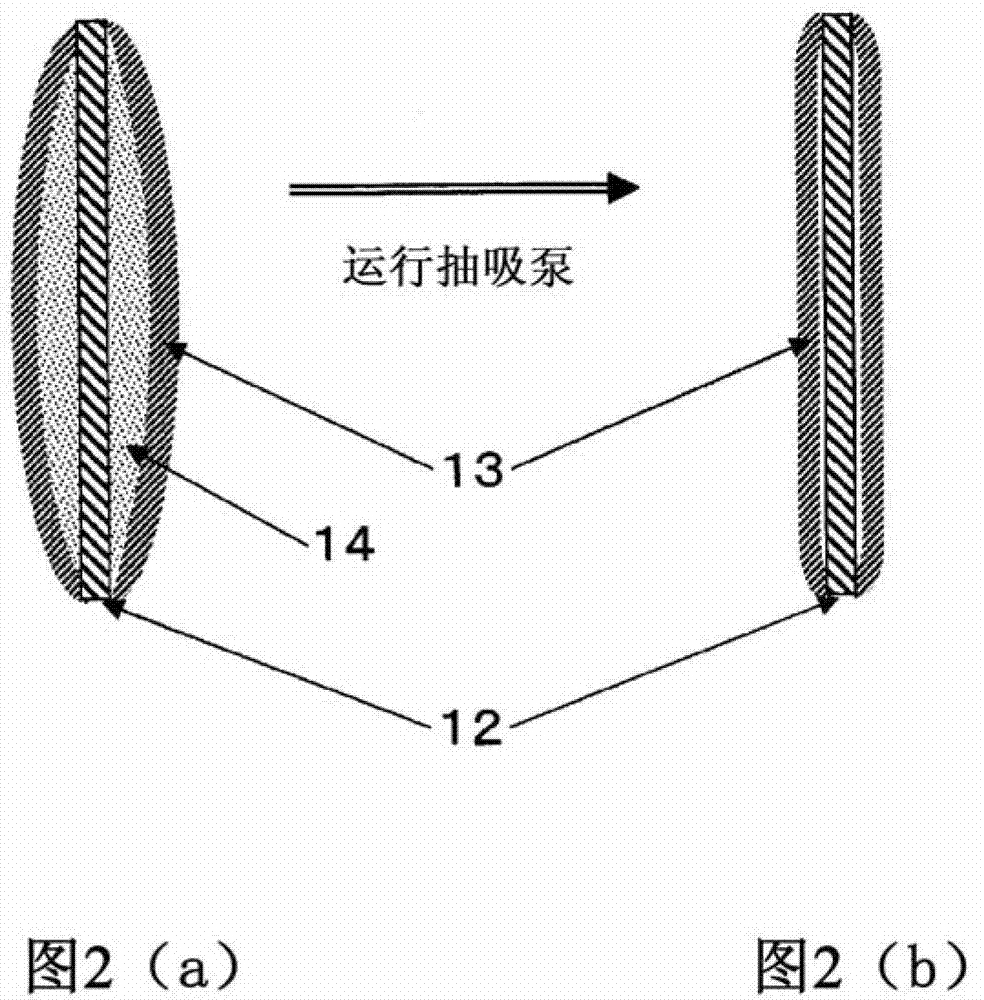

[0081] Chemical cleaning condition 3: 5,000 mg / L of sodium hypochlorite whose pH was adjusted to 12 by adding sodium hydroxide was injected as a first liquid, and contacted for 2 hours. As a result, it was confirmed that pockets were formed in the gap between the film and the support plate. After 2 hours of contact with the first liquid, the residual chemical was suctioned off. 10,000 mg / L of oxalic acid was injected as the second liquid and contacted for 2 hours. As a result, the pockets were dissolved. After 2 hours of contact with the second liquid, the suction filtration operation was restarted.

Embodiment 2)

[0083] Chemical cleaning condition 4: 5,000 mg / L of sodium hypochlorite whose pH was adjusted to 12 by adding sodium hydroxide was injected as a first liquid, and contacted for 2 hours. As a result, it was confirmed that pockets were formed in the gap between the film and the support plate. After 2 hours of contact with the first liquid, the residual chemical was suctioned off. A chemical obtained by adding hydrochloric acid to 10,000 mg / L of oxalic acid to adjust its pH to 1.02 was injected as a second liquid and contacted for 2 hours. As a result, the pockets dissolve. After 2 hours of contact with the second liquid, the suction filtration operation was restarted.

[0084] The research results are shown in Table 2. As a result of the measurement of the respective recovery rates, the recovery rate was as low as 29% in the chemical cleaning condition 1 and as low as 66% in the chemical cleaning condition 2. On the other hand, the recovery rate under chemical cleaning condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com