Preparation method of theaflavin enteric microcapsule, as well as product prepared by preparation method and application of product

A theaflavin, enteric-coated technology, which is applied in the directions of medical preparations without active ingredients, medical preparations containing active ingredients, and applications, can solve the problems of poor stability of theaflavin, narrow application area, low utilization rate, etc. , to achieve the effect of improving poor stability, uniform particle size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

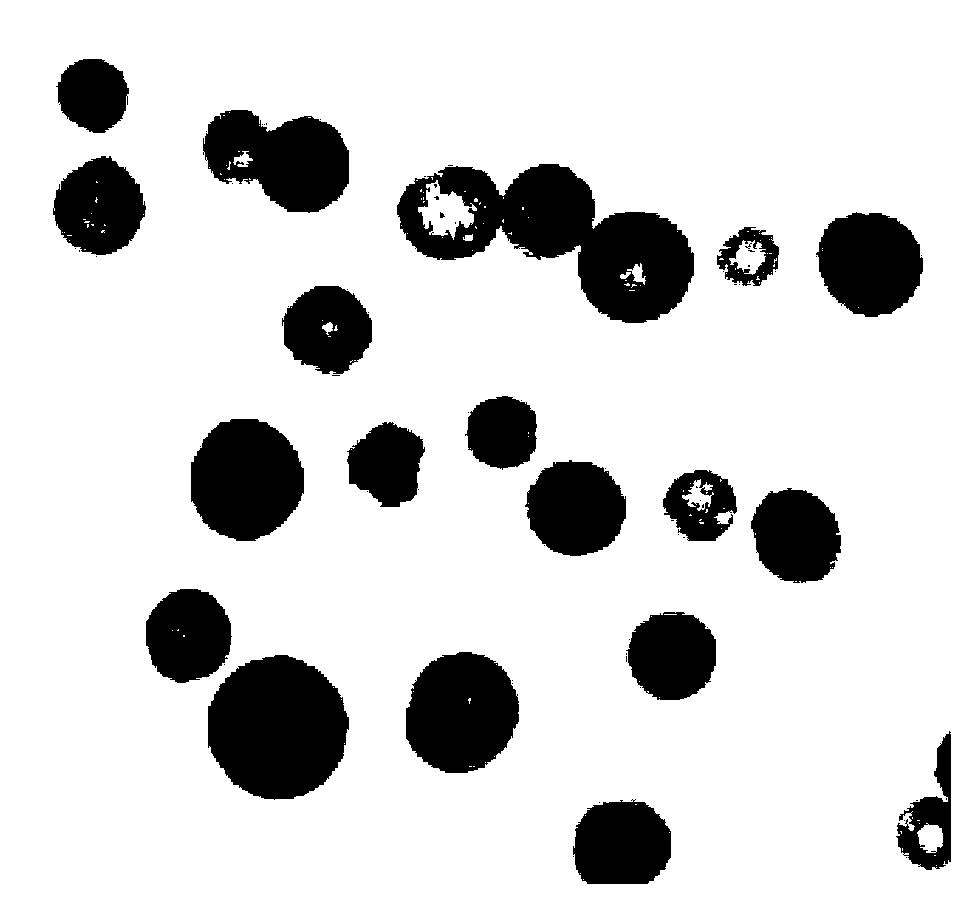

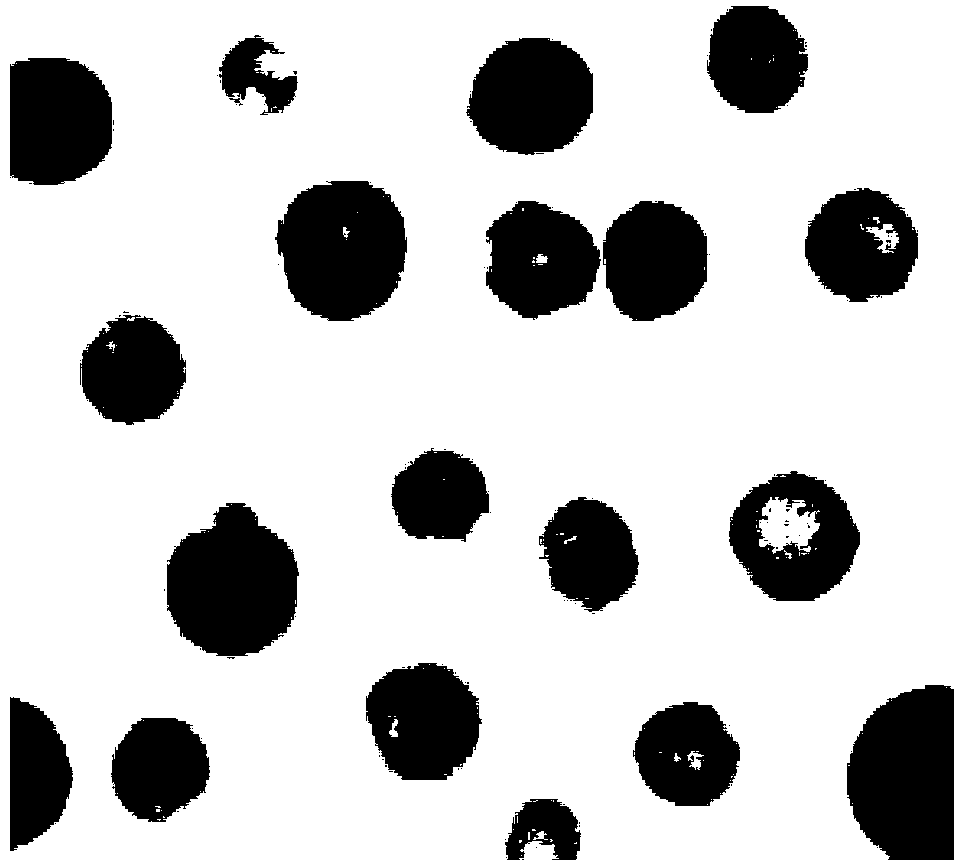

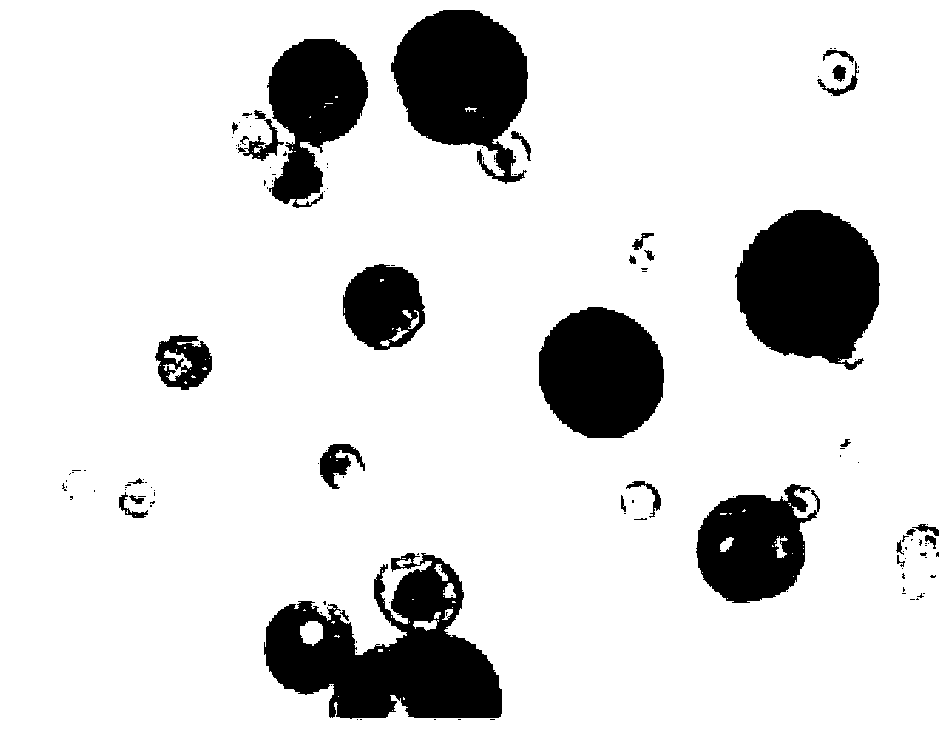

Image

Examples

Embodiment 1

[0052] raw material:

[0053]

[0054] Its steps include:

[0055] (1) Preparation of the capsule material solution: dissolve the capsule material in 95% ethanol aqueous solution to obtain a 4% capsule material ethanol solution; the 4% is the mass percentage of the capsule material relative to the ethanol aqueous solution; the 95% is the volume percentage that ethanol accounts for solution;

[0056] Preparation of the core material emulsion: dissolve the tea extract containing tea pigment in 5L distilled water to obtain a 2% core material solution; the percentage is the mass percentage of the core material relative to water; add stearic acid,

[0057] Stir and ultrasonically emulsify for 30 minutes; the percentage is the mass percentage of stearic acid in the core material solution.

[0058] (2) Mix the capsule material solution with the core material emulsion and stir evenly; add anti-sticking agent and emulsifier B,

[0059] Stir and emulsify to obtain an emulsion, flu...

Embodiment 2

[0062] raw material:

[0063]

[0064]

[0065] Process steps and conditions:

[0066] (1) Preparation of the capsule material solution: dissolve the capsule material in 95% ethanol aqueous solution to prepare a 5% capsule material ethanol solution; the 5% is the mass percentage of the capsule material relative to the ethanol aqueous solution;

[0067] Preparation of the core material emulsion: dissolve the tea extract containing tea pigment in 2L distilled water to obtain a 5% core material solution; the percentage is the mass percentage of the core material relative to water; add stearic acid, stir, and ultrasonically Emulsifying; said percentage is the mass percentage that stearic acid accounts for core material solution.

[0068] (2) Mix the capsule material solution with the core material emulsion, and stir evenly; add anti-sticking agent and emulsifier B, stir and emulsify to obtain an emulsion, and fluidize the emulsion and spray dry it. The spray drying conditio...

Embodiment 3

[0071]

[0072] Process steps and conditions:

[0073] (1) Preparation of the capsule material solution: dissolve the capsule material in 80% ethanol aqueous solution to prepare a 1% capsule material ethanol solution; the 1% is the mass percentage of the capsule material relative to the ethanol aqueous solution;

[0074] Preparation of the core material emulsion: dissolve the tea extract containing theaflavin into 10L distilled water to obtain a 1% core material solution; the percentage is the mass percentage of the core material relative to water; add stearic acid, stir, Ultrasonic emulsification for 30 minutes; said percentage is the mass percentage of stearic acid in the core material solution.

[0075] (2) Mix the capsule material solution with the core material emulsion, and stir evenly; add anti-adhesive agent and emulsifier B, stir and emulsify to obtain an emulsion, fluidize the emulsion and spray dry, and the conditions for spray drying: the inlet air temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com