Tetrapod-like zinc oxide/graphene composite material and preparation method thereof

A technology of four-needle zinc oxide and composite material, applied in the field of four-needle zinc oxide/graphene composite material and preparation thereof, can solve the problems of graphene oxide agglomeration, low efficiency of four-needle zinc oxide, etc., and avoid agglomeration , improve the effect of photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

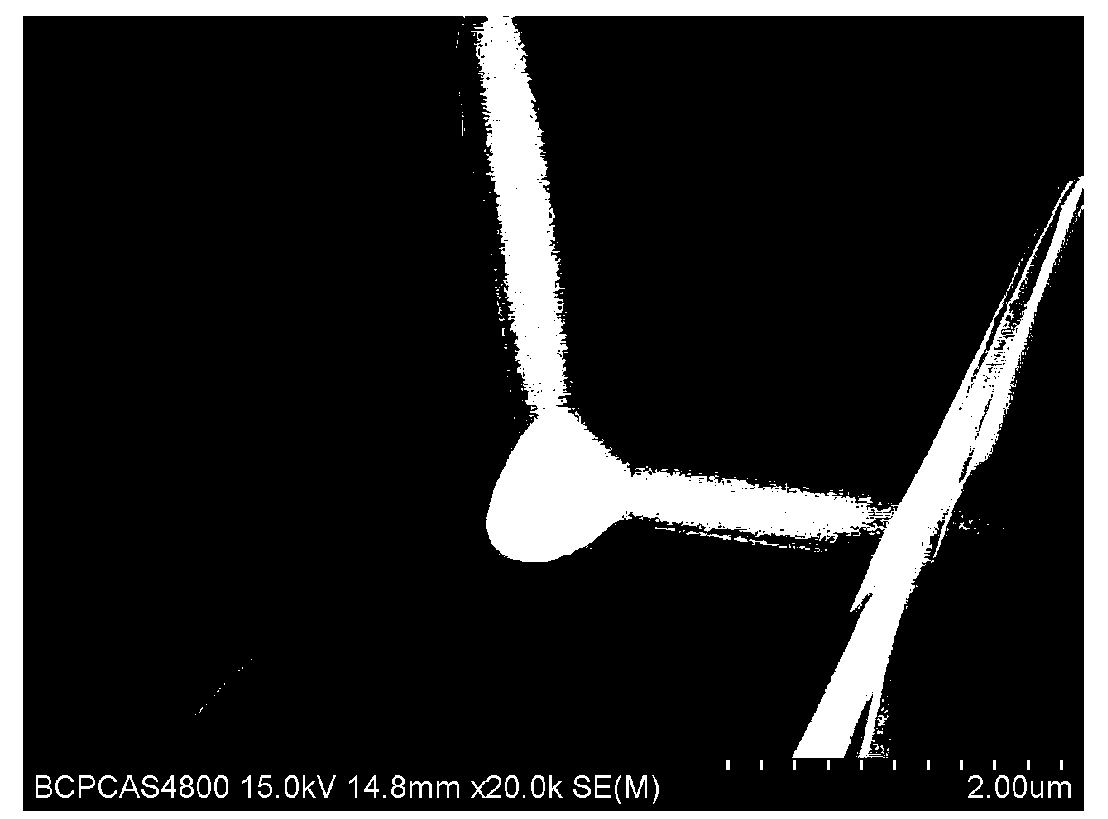

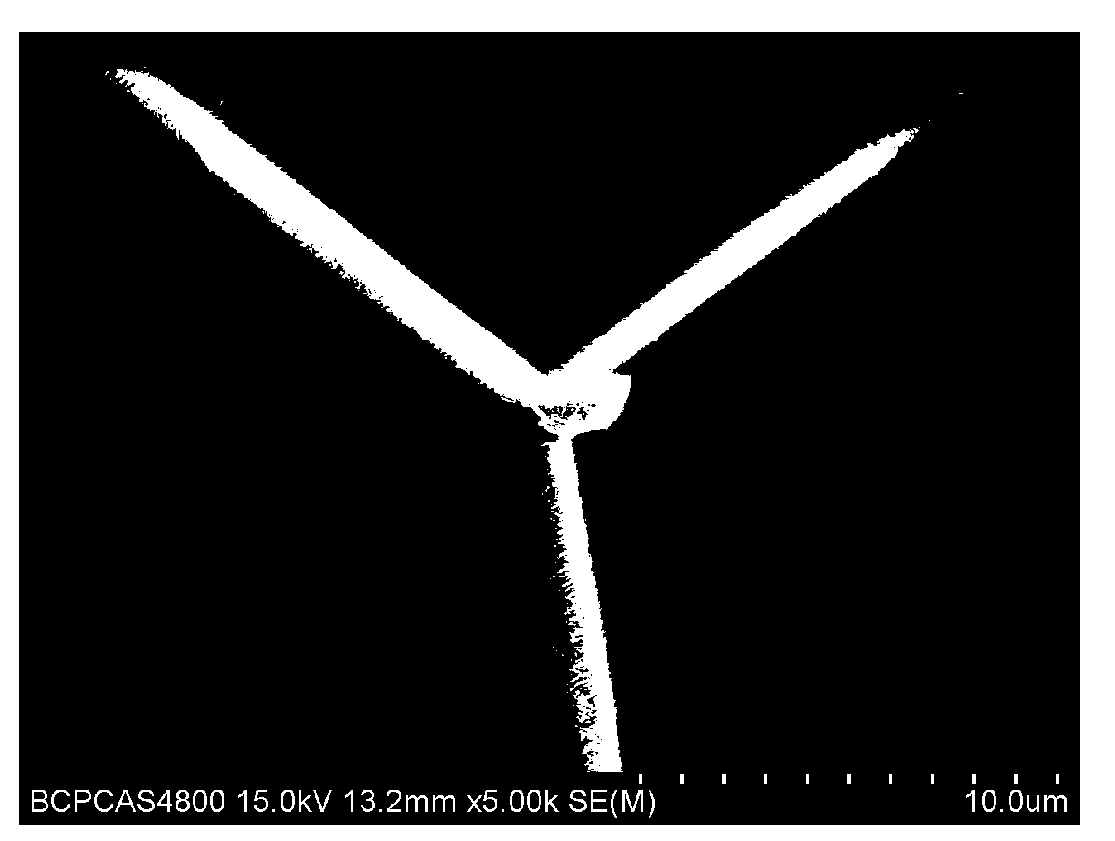

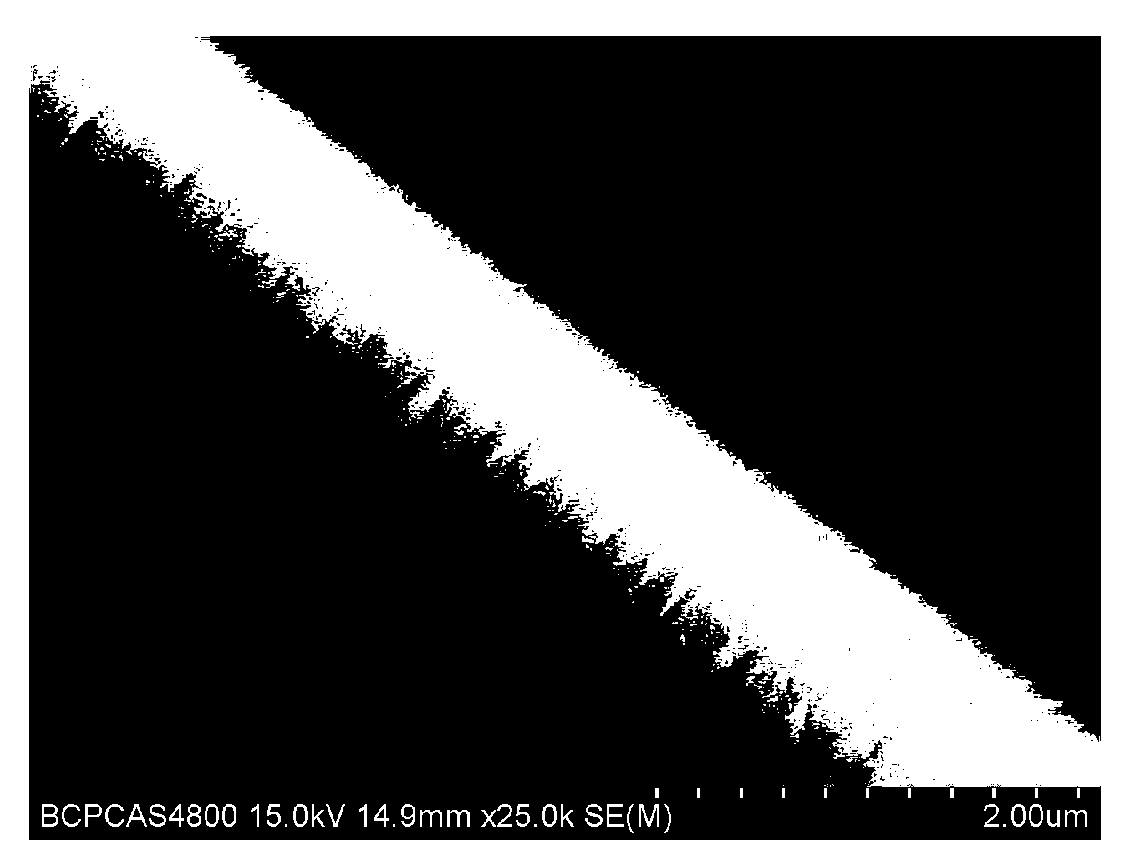

[0019] A tetraacicular zinc oxide / graphene composite material is that graphene nanosheets are grown on the surface of tetraacicular zinc oxide.

[0020] One of the preparation methods of a tetraacicular zinc oxide / graphene composite material, the steps comprising:

[0021] Preparation of step one reaction precursor solution

[0022] Under the protection of nitrogen, dissolve 2.97g zinc nitrate in 120ml pH value of 8, concentration is 0.1mg / ml in the alkaline aqueous dispersion of graphene oxide, stir until completely dissolved, add 120ml anhydrous methanol and 1.2ml poly Ethylene glycol, continue to stir for later use.

[0023] The preparation of step 2 reaction intermediate

[0024] Put the precursor liquid prepared in step 1 into an airtight container, carry out hydrothermal reaction at 200°C, the reaction time is 6h, after natural cooling, wash with deionized water and ethanol alternately to neutrality, and obtain zinc oxide / graphite after drying alkenes intermediates. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com