Method for purification of baddeleyite to prepare high purity zirconia

The technology of zirconia and baddeleyite is applied in the purification field of high-purity zirconia.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

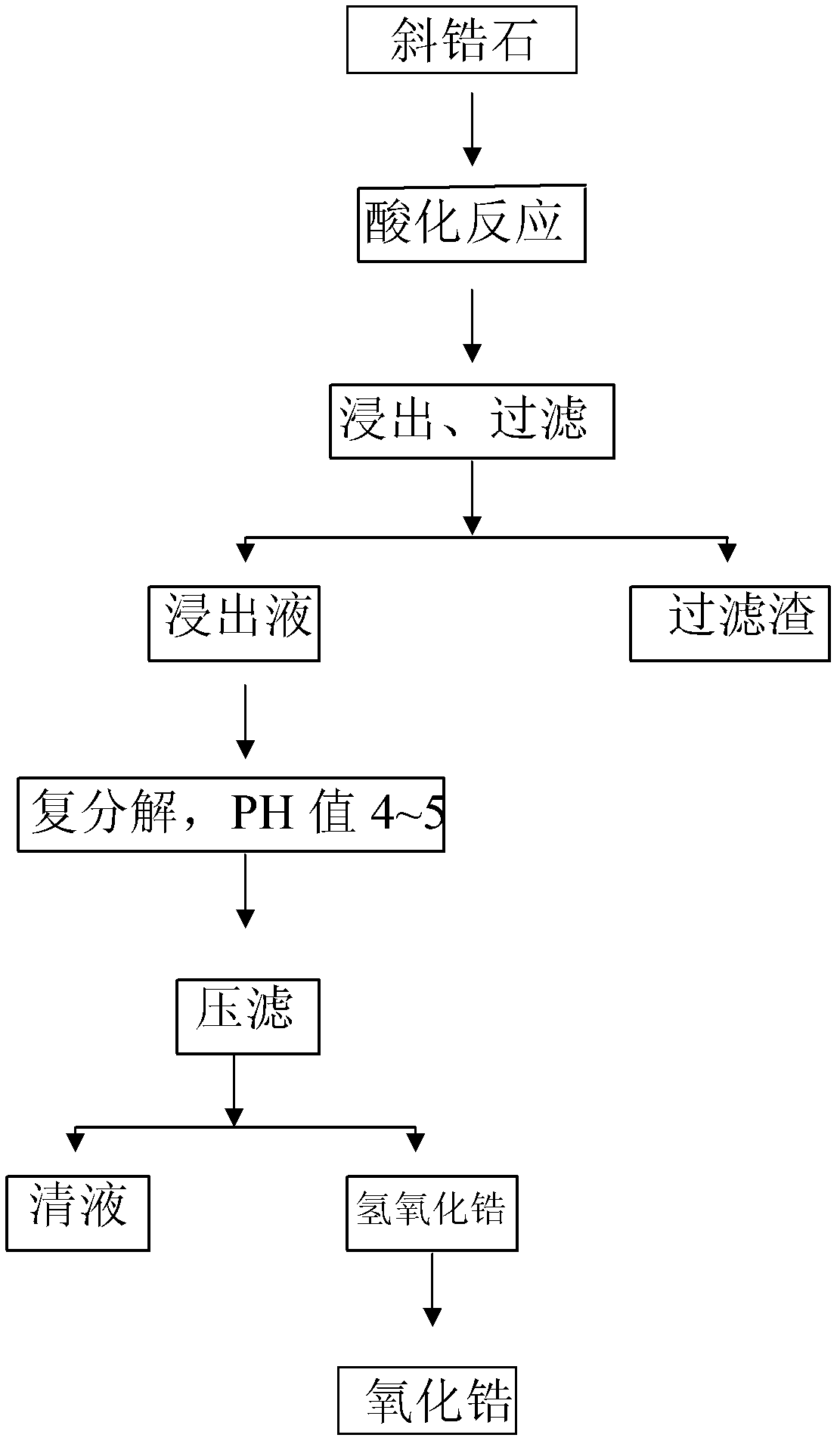

Image

Examples

Embodiment 1

[0021] (1) Ingredients: mix baddeleyite powder, industrial ammonium sulfate and sulfuric acid in a mass ratio of 1:3:5;

[0022] (2) Acidification reaction: the above mixture is roasted at 150° C. to make it react to generate sulfate, and the conversion rate is ≥ 93%;

[0023] (3) Leaching: adding sulfate into water for leaching, the temperature is controlled at 55°C, the solid-to-liquid ratio of the product after the acidification reaction and water is 1:4.5, and the leaching time is controlled at 2.5h;

[0024] (4) Filtration: after the leaching ends, carry out solid-liquid separation with a plate and frame machine, and press filter to remove the clear liquid;

[0025] (5) metathesis: neutralize the clear liquid with ammonia water to a pH value of 4;

[0026] (6) Press filtration: the metathesis reaction product is press-filtered with a plate and frame machine;

[0027] (7) Washing: the filter residue that press filtration obtains is washed 3 times with water;

[0028] (8...

Embodiment 2

[0030] (1) Ingredients: mix oblique zirconium powder, ammonium sulfate and sulfuric acid in a mass ratio of 1:2:4;

[0031] (2) Acidification reaction: the above mixture is roasted at 950° C. to make it react to generate sulfate, and the conversion rate is ≥ 93%;

[0032] (3) Leaching: adding sulfate into water for leaching, the temperature is controlled at 55°C, the solid-to-liquid ratio of the product after the acidification reaction and water is 1:5, and the leaching time is controlled at 2.5h;

[0033] (4) Filtration: after the leaching ends, carry out solid-liquid separation with a plate and frame machine, and press filter to remove the clear liquid;

[0034] (5) metathesis: neutralize the clear liquid with ammonia water to a pH value of 5;

[0035] (6) Press filtration: the metathesis reaction product is press-filtered with a plate and frame machine;

[0036] (7) Washing: the filter residue that press filtration obtains is washed 5 times with water;

[0037] (8) Roast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com