Preparation method of silicon-steel-level magnesium oxide coating

A technology of magnesium oxide and silicon steel grade, which is applied in the field of preparation of magnesium compounds, can solve the problems of long process flow, poor physical properties, and low chemical purity, and achieve high chemical purity, low hydration rate, and good suspension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Example 1: Select natural aphanitic magnesite to produce light-burned magnesia powder; digest light-burned magnesia, neutralize and decalcify with acid and alkali, react at a temperature of 15°C for 5 minutes to generate hydrogen oxide Magnesium, then washed with water, filtered, dried, and then calcined at a temperature of 1050°C for 1.5 hours to obtain high-purity light-burned magnesium oxide powder; processed into the required micron-sized particle size segment by jet milling.

Embodiment 2

[0010] Example 2: Select natural aphanitic magnesite to produce light-burned magnesia powder; digest light-burned magnesia, neutralize and decalcify with acid and alkali, react at a temperature of 20°C for 10 minutes to generate hydrogen oxide Magnesium, then washed with water, filtered, dried, and then calcined at a temperature of 1100°C for 2.0 hours to obtain high-purity light-burned magnesium oxide powder; processed into the required micron-sized particle size segment by jet mill.

Embodiment 3

[0011] Example 3: Select natural aphanitic magnesite to produce light-burned magnesia powder; digest the light-burned magnesia, neutralize and decalcify with acid and alkali, react at a temperature of 30°C for 15 minutes to generate hydrogen oxide Magnesium, then washed with water, filtered, dried, and then calcined at a temperature of 1150°C for 2.5 hours to obtain high-purity light-burned magnesium oxide powder; processed into the required micron-sized particle size segment by jet milling.

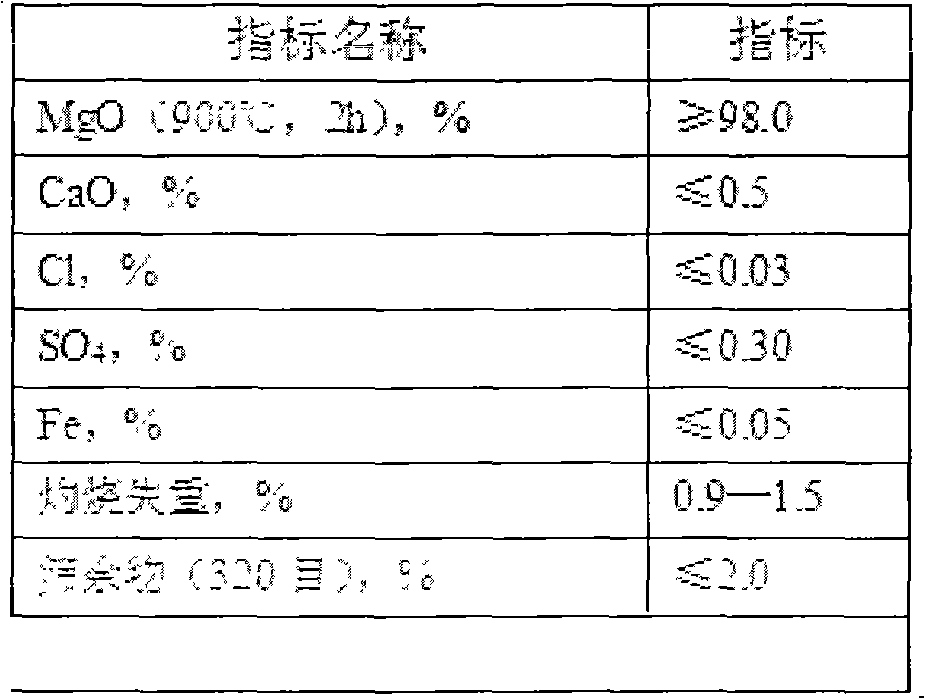

[0012] Through practice, its technical index of the silicon steel grade magnesia coating that the inventive method is made is as shown in table 1:

[0013] Table 1 technical indicators

[0014]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com