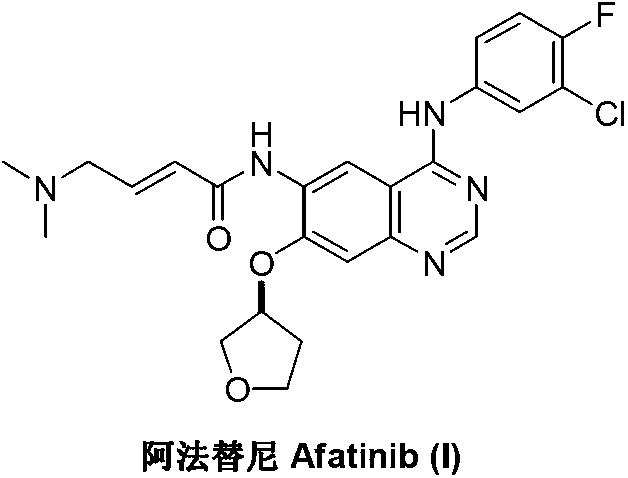

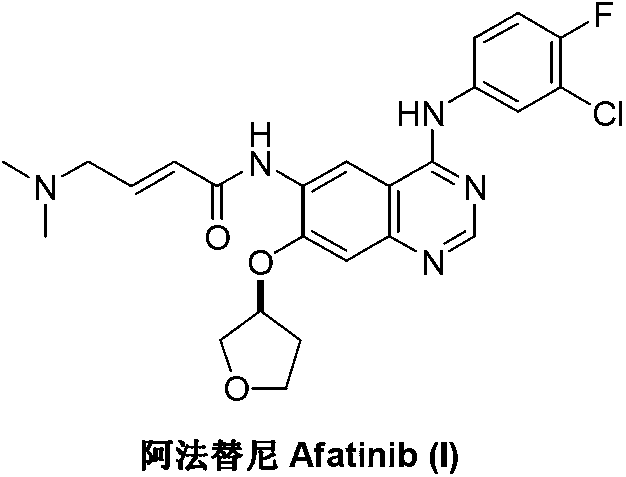

Method for preparing Afatinib

A technology of afatinib and amino, which is applied in the field of preparation of afatinib, can solve the problems of unsuitability for industrialization, low total yield, and many steps, and achieve the effect of promoting the development of economy and technology, and the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

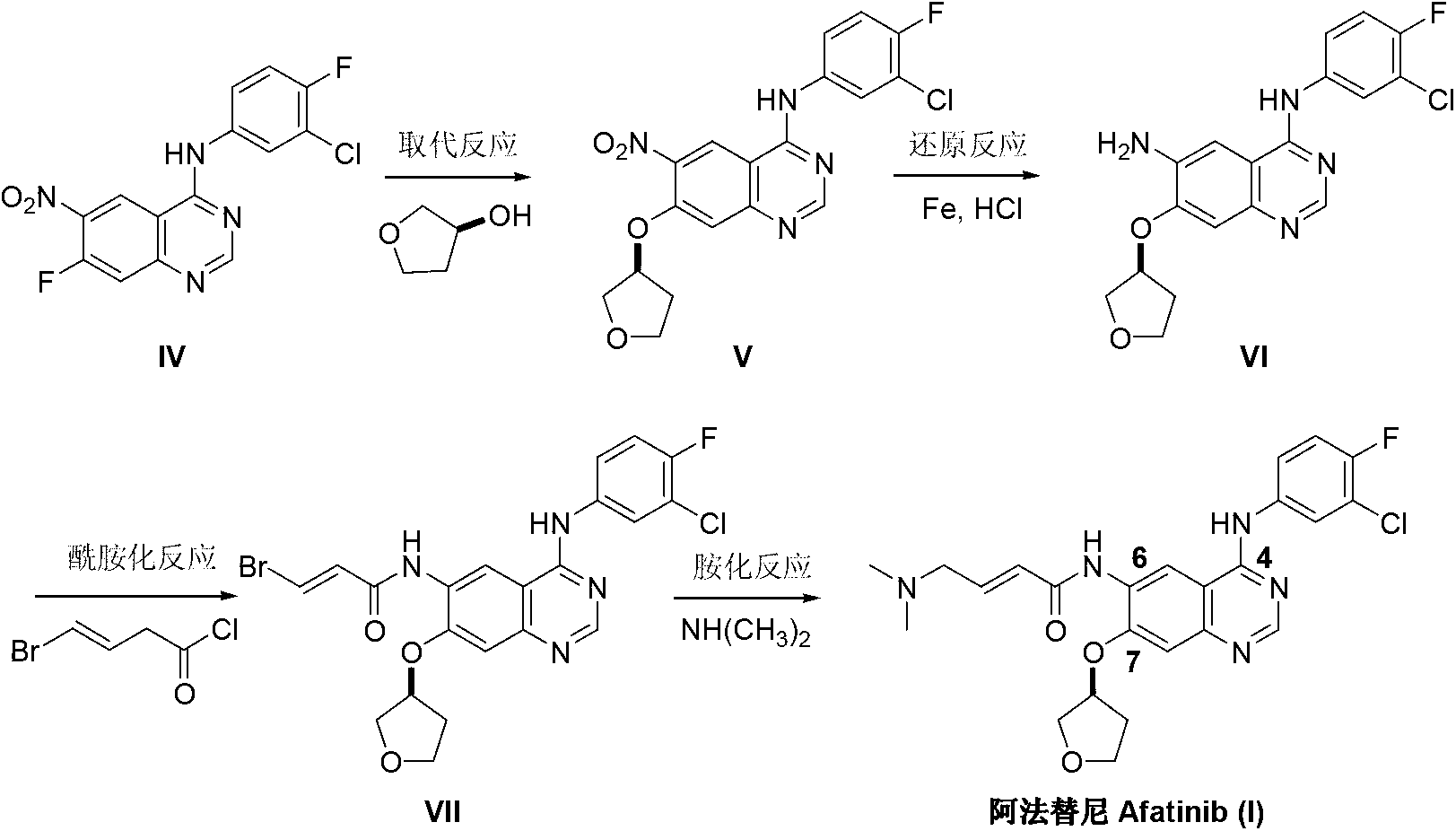

Method used

Image

Examples

Embodiment 1

[0025] Add 3-chloro-4-fluoroaniline (14.5g, 0.10mol), N,N-dimethylformamide dimethyl acetal (DMF-DMA) (17.8mL, 0.14mol) and toluene into a 500mL three-necked flask 150mL, add 2.8mL of catalyst anhydrous acetic acid under stirring. The temperature was raised to 105-110° C., and the temperature was maintained for 3 hours to react (methanol was collected with an oil-water separator), and the reaction was monitored by TLC to complete. Toluene was recovered by distillation under reduced pressure at 50° C. to obtain 19.5 g of a colorless oil with a yield of 97.4%. The colorless oil can be directly used in the following reaction without separation.

[0026] The above oil was dissolved in 150 mL of anhydrous acetic acid, and transferred to a 500 mL three-necked flask. Add 2-cyano-4-[4-(N,N-dimethylamino)-1-oxo-2-buten-1-yl]amino-5-[(S)-(tetrahydrofuran-3- yl)oxy]aniline (II) (23.8 g, 0.072 mol). After stirring, the temperature was raised to 115-120° C. and kept under reflux for 4 h...

Embodiment 2

[0028] Add 3-chloro-4-fluoroaniline (14.5g, 0.10mol), N,N-dimethylformamide dimethyl acetal (DMF-DMA) (17.8mL, 0.14mol) and toluene into a 500mL three-necked flask 150mL, add catalyst anhydrous formic acid 2.5mL under stirring. The temperature was raised to 105-110° C., and the temperature was maintained for 4 hours (methanol was collected with an oil-water separator), and the reaction was monitored by TLC. Toluene was recovered by distillation under reduced pressure at 50° C. to obtain 19.2 g of a colorless oil with a yield of 96.2%. The colorless oil can be directly used in the following reaction without separation.

[0029] The above oil was dissolved with 25mL of anhydrous acetic acid and 125mL of toluene, and transferred to a 500mL three-necked flask. Add 2-cyano-4-[4-(N,N-dimethylamino)-1-oxo-2-buten-1-yl]amino-5-[(S)-(tetrahydrofuran-3- yl)oxy]aniline (II) (22.5 g, 0.068 mol). Stir, raise the temperature to 120-130° C., and maintain reflux for 4 hours, and monitor th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com