Eucommia ulmoides rubber refining method

A refining method, the technology of eucommia gum, is applied in the field of refining the natural plant eucommia ulmoides by leaching, which can solve the problems of high impurity content in the finished gum, impurity that cannot be effectively removed, and quality reduction of eucommia gum, and achieve high raw material utilization rate, High efficiency of impurity removal, effect of reducing the content of flavonoids and polysaccharides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1) Prepare materials

[0052] The natural air-dried Eucommia leaves were shredded into fragments with a particle size of ≤4 mm for later use.

[0053] 2) Pretreatment of raw materials

[0054] A. Extract chlorophyll and β-carotene

[0055] Add 2 kg of eucommia leaf fragments into an ethanol solution with a mass percentage concentration of 90%, heat, soak to extract chlorophyll and β-carotene, and extract 4 times in total. ℃, 45 ℃, 50 ℃, filter after each extraction, and combine the filtrates; wherein, the ratio of the weight (dry weight) of Eucommia leaves to the volume of ethanol solution is 1:10 during each extraction, that is, to 2kg Eucommia leaves Add 20L of ethanol solution whose mass percentage concentration is 90%; wherein, in the first extraction process, the extraction temperature is 35°C, and the extraction time is 24h; the second extraction temperature is 40°C, and the extraction time is 18h; The extraction temperature is 45°C, and the extraction time is ...

Embodiment 2

[0073]Extracting chlorophyll and β-carotene in the raw material pretreatment process except that the weight (dry weight) of Eucommia leaves and the volume ratio of the ethanol solution with a mass percentage concentration of 90% during each extraction is 1:15, the first and second Two, the third, and the fourth extraction time are respectively 12h, 12h, 12h, and 12h; in the step of extracting lignans, the weight (dry weight) of leaves of Eucommia ulmoides and the mass percent concentration of 80% ethanol are removed The volume ratio of the solution is 1:15, and the first, second, third, and fourth extraction times are 12h, 12h, 12h, and 12h respectively; in the steps of extracting aucubin, chlorogenic acid, and protein, except for each The weight (dry weight) of leaves of Eucommia ulmoides during extraction is 1: 15 with the mass percent concentration of the ethanol solution volume ratio of 70%, and the first, second, third, and fourth extraction times are respectively 12h, 12h...

Embodiment 3

[0078] Except that the mass percent concentration of NaOH solution in the step of extracting flavonoids and polysaccharides in the raw material pretreatment process is 1%, the rest is the same as in Example 1.

[0079] The process of extracting eucommia gum is the same as that in Example 1 except that the relative density of the petroleum ether concentrate obtained by recovering petroleum ether is 1.5.

[0080] In the process of purifying eucommia gum, except that every 100ml of concentrated solution adds 10ml of acetone, and the relative density of the filtrate is 1.5, all the other are the same as in Example 1.

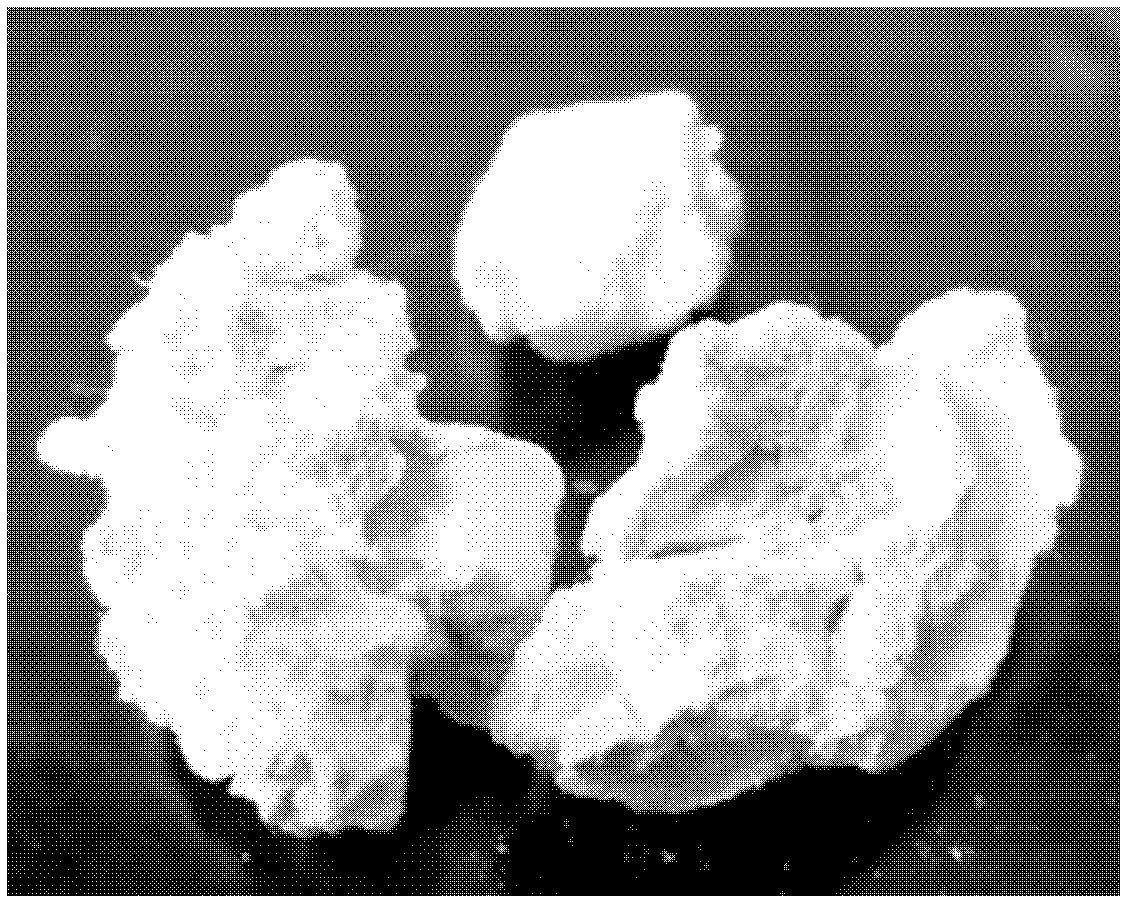

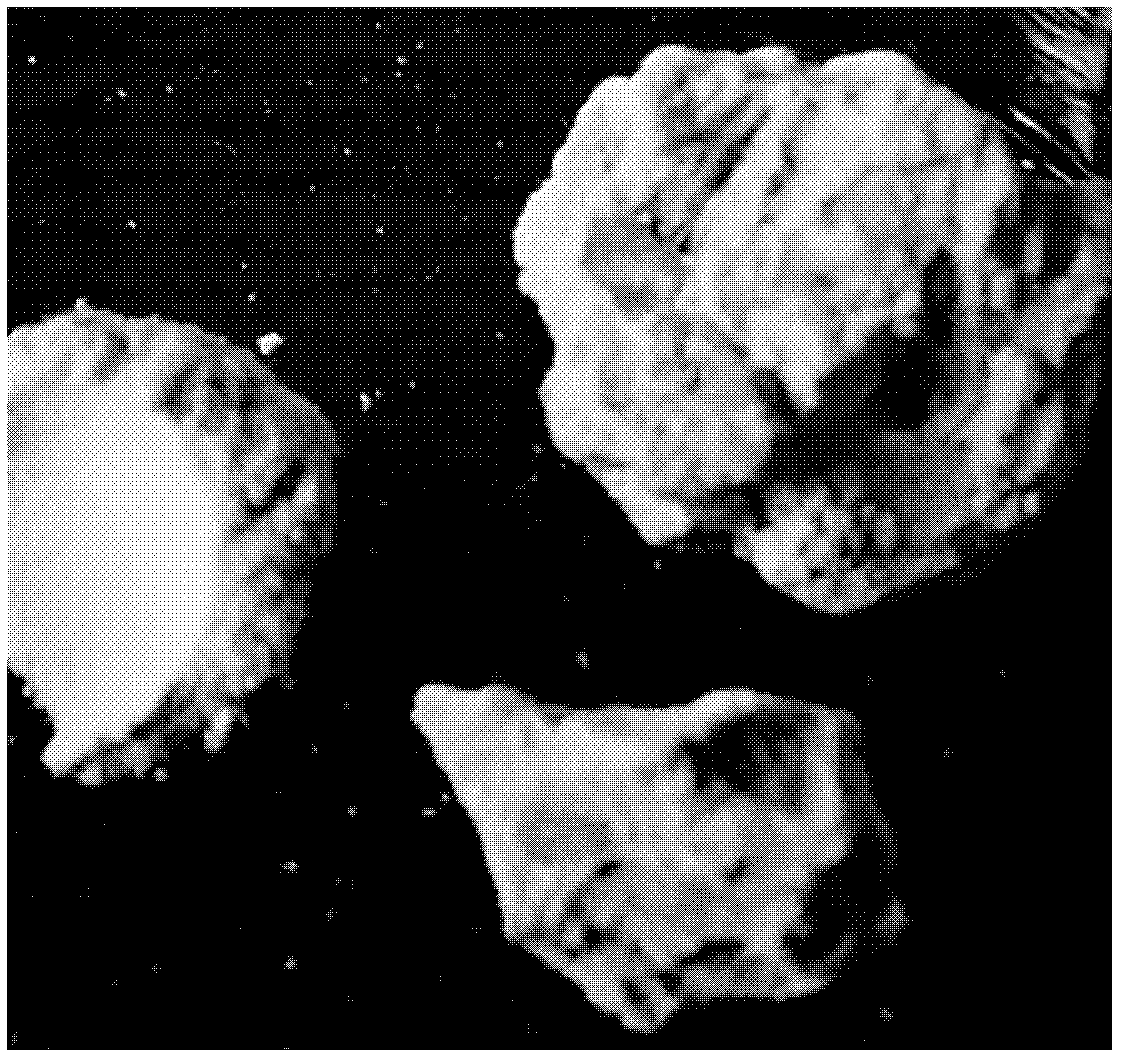

[0081] Purified to obtain 42.2g Eucommia gum, the yield of Eucommia gum was 2.11%, the color of Eucommia gum was white, the texture was fine and elastic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com