Biomass hydrogen-donating pyrolysis technique of naphthenic base oil in presence of hydrogen-donating distillate oil

A biomass and distillate technology, which is applied in the petroleum industry, biofuels, special forms of dry distillation, etc., can solve problems such as poor quality, reduced coke yield, and high oxygen content in bio-oil, so as to improve quality and reduce coke yield , the effect of reducing the oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

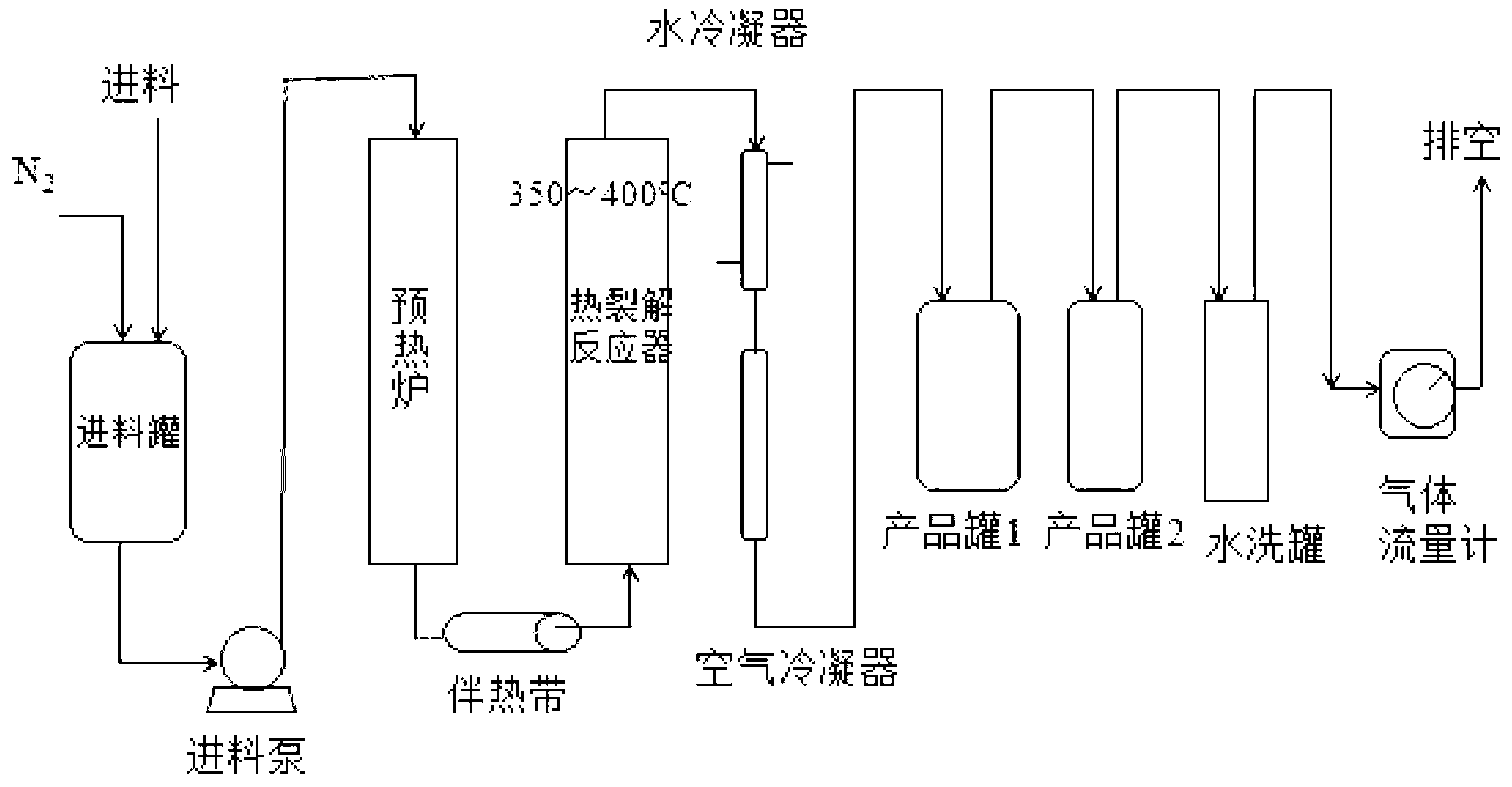

Method used

Image

Examples

Embodiment 1

[0012] Example 1, waste sawdust in the wood factory is used as raw material, after washing and drying, it is preheated to 120°C and then enters from the bottom of the pyrolysis reactor with a volume space velocity of 1.0h -1 , Control the reaction temperature in the reactor to 350°C. The bio-oil and solid coke produced were reacted and collected, and the yield of bio-oil was calculated to be 29.0%, the yield of coke was 50.4%, and the conversion rate of sawdust was 49.6%. The elemental analysis of the bio-oil showed that the oxygen element content was 37.2%.

Embodiment 2

[0013] Example 2, waste sawdust in the wood factory was used as raw material, washed and dried and mixed with distillate oil at 400-460°C in Venezuelan crude oil, wherein the mass of hydrogen-donating distillate accounted for 5% of the mass of sawdust. The mixture is preheated to 120°C and enters from the bottom of the pyrolysis reactor with a volume space velocity of 1.0h -1 , Control the reaction temperature in the reactor to 350°C. Reaction and collection of bio-oil and solid coke, deducting the hydrogen-donating agent alone conversion blank after calculation, the yield of bio-oil converted from sawdust in the reaction was 31.0%, the yield of coke was 40.8%, and the conversion rate of sawdust was 59.2% . The elemental analysis of the bio-oil showed that the oxygen content was 34.6%.

Embodiment 3

[0014] Example 3, waste sawdust in the wood factory was used as raw material, washed and dried, mixed with 460-500°C distillate oil in Venezuelan crude oil, wherein the mass of hydrogen-donating distillate accounted for 10% of the mass of sawdust. The mixture is preheated to 120°C and enters from the bottom of the pyrolysis reactor with a volumetric space velocity of 0.5h -1 , control the reaction temperature in the reactor at 380°C, react and collect bio-oil and solid coke, calculate and deduct the hydrogen-donating agent alone conversion blank, get the yield of bio-oil converted from sawdust in the reaction is 34.7%, and the yield of coke is 34.7%. It was 38.3%, and the sawdust conversion rate was 61.7%. The elemental analysis of the bio-oil showed that the oxygen element content was 32.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com