Terahertz metamaterial unit structure and preparation, adjusting and control method thereof

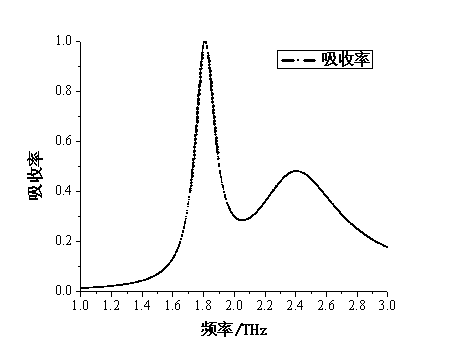

A unit structure, metamaterial technology, applied in the field of metamaterials and terahertz detection, can solve problems such as unfavorable practical application and theoretical research, and achieve the effect of simple structure, simple design, and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

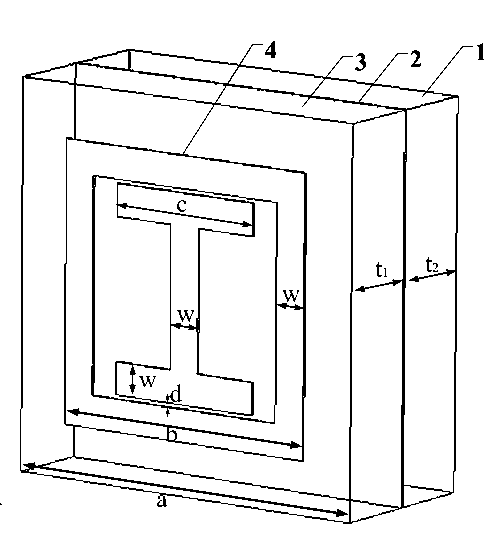

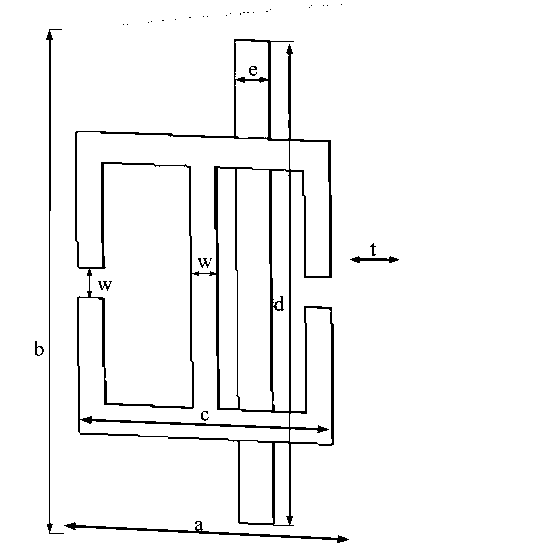

[0036] The bottom layer provided by the present invention is a continuous metal film, the middle layer is a dielectric layer, and the surface layer is patterned into a metamaterial structure composed of two metal parts: "I" inside and "square frame" on the outside, which has a special terahertz response performance. The embodiment of making the metamaterial structure in the present invention is as follows: (1) choose a single crystal silicon wafer as the substrate 1 of the metamaterial, after cleaning, dry it with high-purity nitrogen, and set it aside; (2) on the surface of the substrate 1, Use an electron beam evaporation system to deposit a continuous gold film with a thickness of 5-2000 nm as the underlying metal 2 of the metamaterial; (3) Spin-coat a layer of 0.05-40 μm thick gold on the surface of the above-mentioned continuous gold film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com