Preparation method of bone repair bracket with osteoid poriform regeneration channel structure

A channel structure, osteoid technology, applied in medical science, prosthesis, etc., can solve the problems of new tissue necrosis, poor permeability, cell apoptosis, etc., to promote bone tissue regeneration and repair, improve mechanical properties, and meet popularization and application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

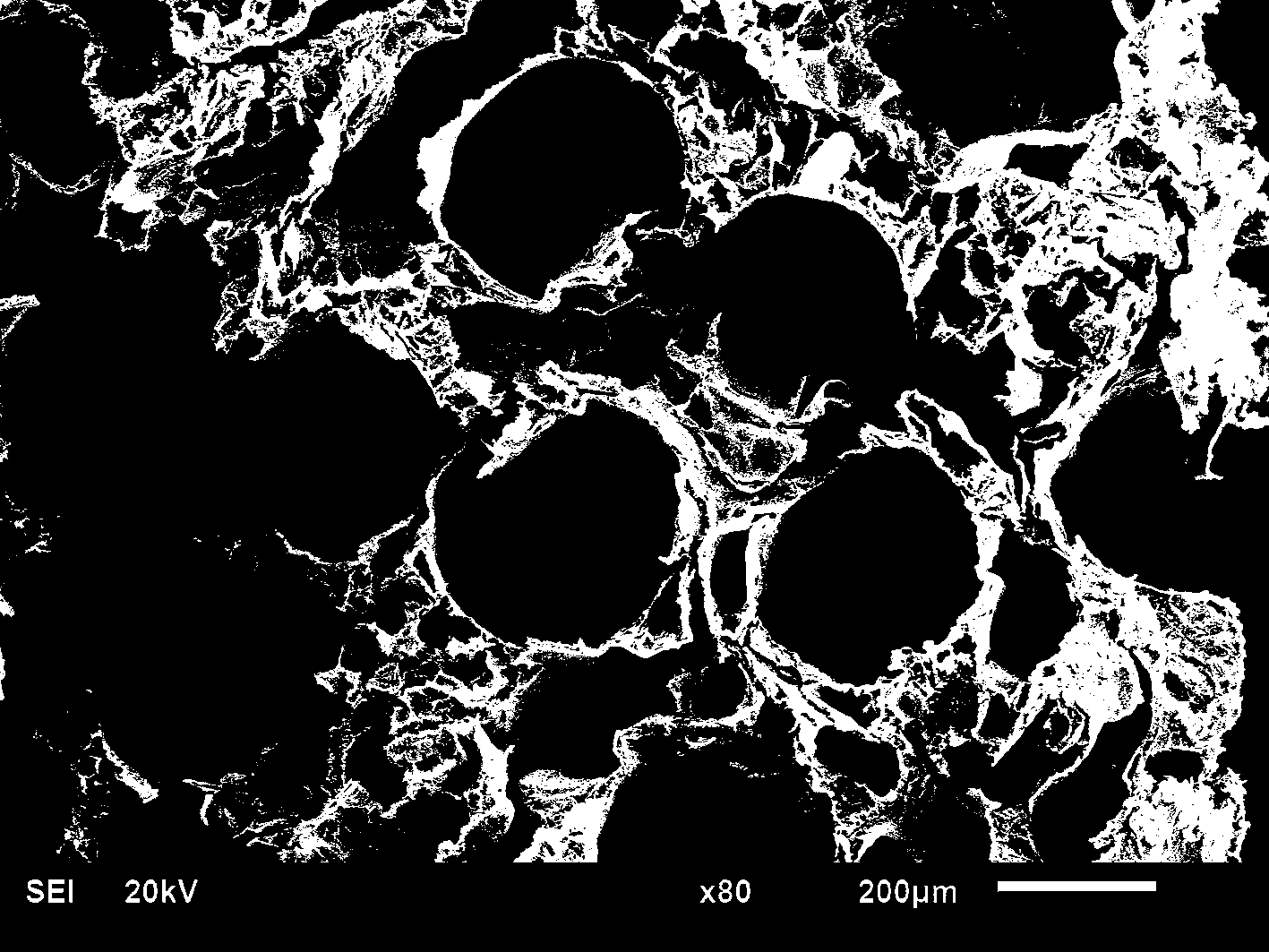

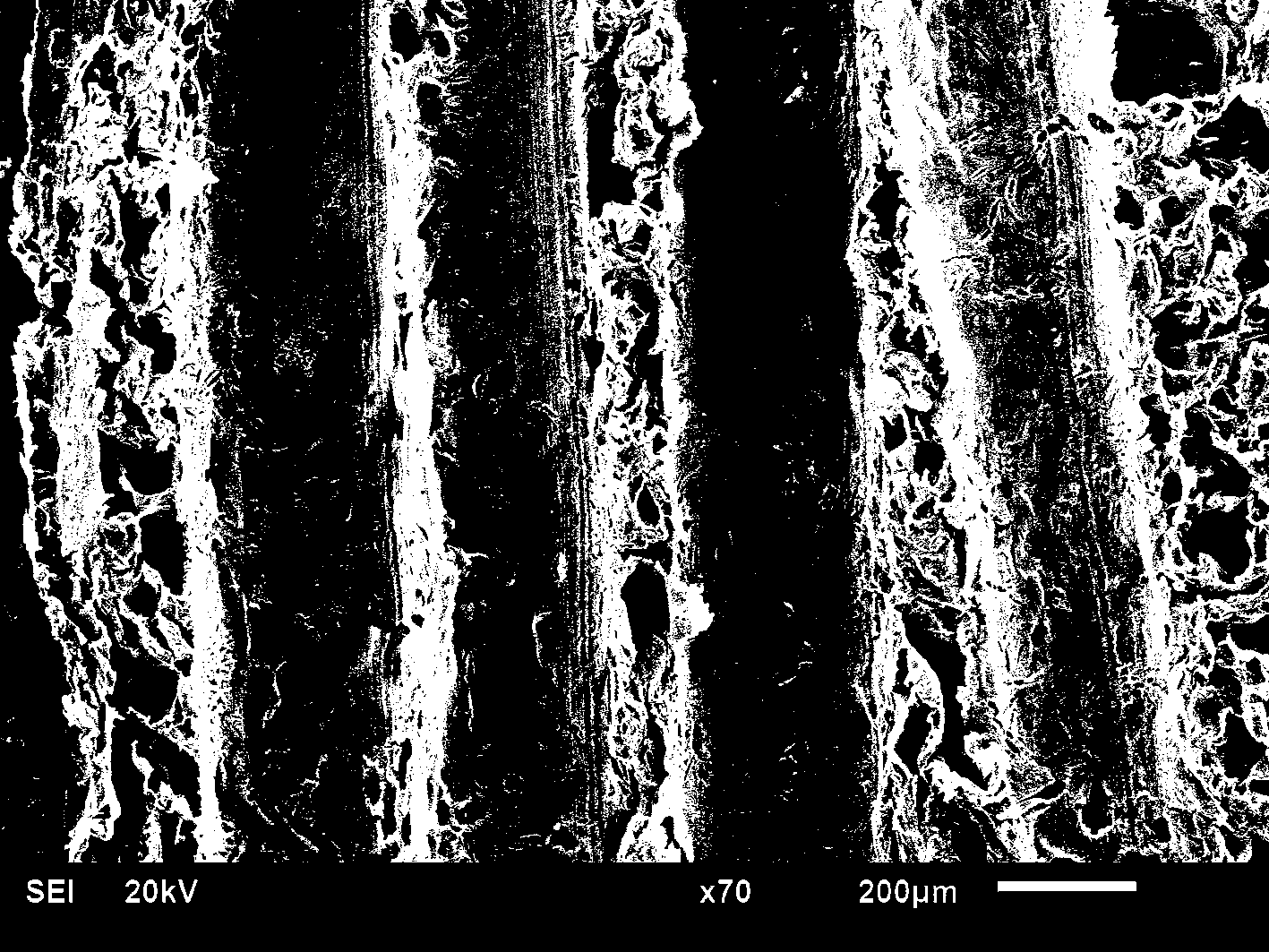

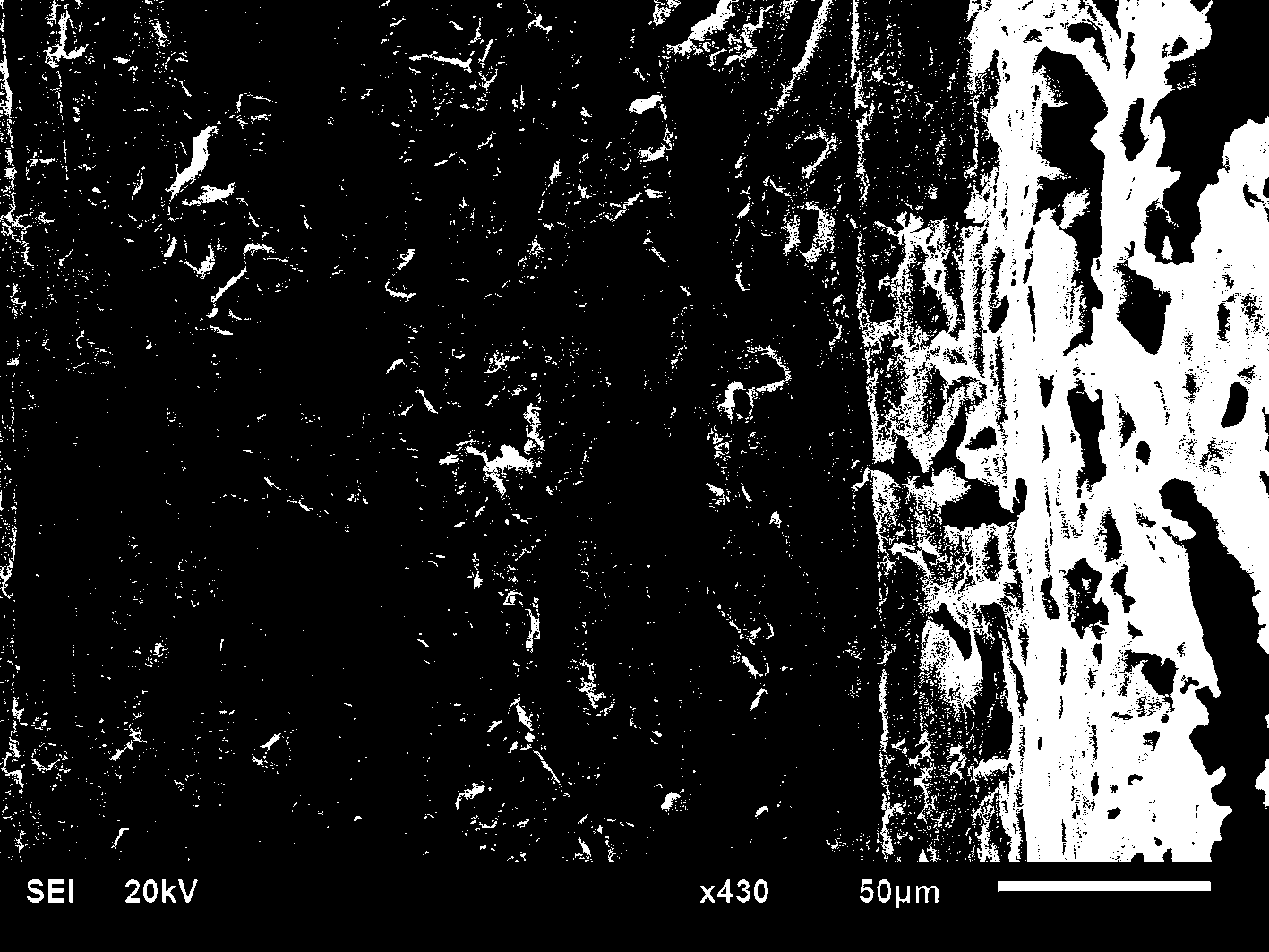

[0026] According to literature (Li JD, Zuo Y, Cheng XM, Yang WH, Wang HN, Li YB, Preparation and characterization of nano-hydroxyapatite / polyamide 66 composite GBR membrane with asymmetric porous structure, Journal of Material Science-materials in medicine, 2009, Vol.30, No.5: 1031-1038) reported the preparation of nano-apatite (n-HA)-polyamide 66 (PA66) composite slurry. Evaporate the ethanol solvent by heating, so that the n-HA-PA66 composite slurry can reach a suitable viscosity. The composite slurry is evenly coated on 304 stainless steel wires with a diameter of 300 μm, and then 40 stainless steel wires coated with slurry are bundled into a bundle and placed in a PE heat-shrinkable tube, and one end of the heat-shrinkable tube is sealed. Heat the heat shrink tubing to 90°C for 0.5 hour to allow the heat shrink tubing to start shrinking. Heating was continued at elevated temperature to 95°C and maintained for 4 hours. After the material is completely cured, remove the he...

Embodiment 2

[0028] Prepare nano-apatite-polyamide 66 (n-HA-PA66) composite material according to the method reported in CN1544099, and then use methanol as a solvent to prepare n-HA-PA66 composite slurry with suitable viscosity. The composite slurry was uniformly coated on 304 stainless steel wires with a diameter of 150 μm, and then 50 stainless steel wires coated with the slurry were bundled into a bundle and placed in a PET heat-shrinkable tube, and one end of the heat-shrinkable tube was sealed. Heat the heat shrink tubing to 80°C for 1 hour to allow the heat shrink tubing to start shrinking. Elevate the temperature and continue heating to 100°C for 6 hours. After the material is completely cured, remove the heat-shrinkable tube, soak it in deionized water for 3 hours, and pull out the stainless steel wire after the material swells. The material was then ultrasonically cleaned in deionized water for 5 times, each time for 5 minutes, and dried to obtain a bone repair scaffold with an ...

Embodiment 3

[0031] According to the method described in the literature described in Example 1, nano-apatite-polyamide 66 (n-HA-PA66) composite slurry was prepared using propanol as a solvent. Evaporate the solvent propanol by heating, so that the n-HA-PA66 composite slurry can reach a suitable viscosity. The composite slurry is uniformly coated on 304 stainless steel wires with a diameter of 500 μm, and then 40 stainless steel wires coated with slurry are bundled into a bundle and placed in a PE heat-shrinkable tube, and one end of the heat-shrinkable tube is sealed. Heat the heat shrink tubing to 110°C for 2 hours to allow the heat shrink tubing to start shrinking. Increase the temperature and continue heating to 150° C. and maintain for 3 hours. After the material is completely cured, remove the heat-shrinkable tube, soak it in deionized water for 3 hours, and pull out the stainless steel wire after the material swells. The material was then ultrasonically cleaned in deionized water f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com