All-biological controllable and degradable bone nail and using method thereof

An all-biological, bone-nail technology, applied in internal bone synthesis, medical science, fastening devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

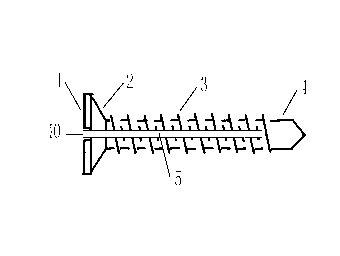

Embodiment 1

[0018] Embodiment 1: Take a number of carbon dioxide copolymers and additives, and the composition parts by weight are: 100 parts of carbon dioxide copolymers, 5-15 parts of additives. Dry for 8 hours, use plastic processing methods such as mixing, granulation, extrusion and calendering, and punching to make outer layer threaded bone screws. The center of the outer layer threaded bone nails is made into a threaded hole, and the rear end of the outer layer screw is made into a standard " The "cross" screw is used to implant it into the bone hole, and the magnesium alloy screw is installed in the threaded hole, and the top of the magnesium alloy nut is also designed as a standard "cross" screw for implanting it into the outer threaded nail Inside, the parts by weight of the magnesium alloy are: 100 parts of magnesium alloy: 1-3 parts of manganese: 0.5-2 parts of zinc: 1-5 parts of Ca. The magnesium alloy screw is used in conjunction with the outer layer screw. After the magnesi...

Embodiment 2

[0019] Embodiment 2: A number of carbon dioxide copolymers and additives are taken, and the composition parts by weight are: 100 parts of carbon dioxide copolymers, 10-50 parts of additives. Dry for 8 hours, use plastic processing methods such as mixing, granulation, extrusion and calendering, and punching to make outer threaded bone screws. The center of the outer layer threaded bone nails is made into a threaded hole. A longitudinal notch is made on the rear end of the outer layer screw to make a standard "cross-shaped" thread for implanting it into the bone hole. Magnesium alloy screws are installed in the threaded hole, and the top of the magnesium alloy nut is also designed to be a standard "cross-shaped" thread. The "cross" screw is used to implant it into the outer threaded nail. The composition of the magnesium alloy is: 100 parts of magnesium alloy: 1-3 parts of manganese: 0.5-2 parts of zinc: 1-5 parts of Ca. The magnesium alloy threaded nail is used in combination w...

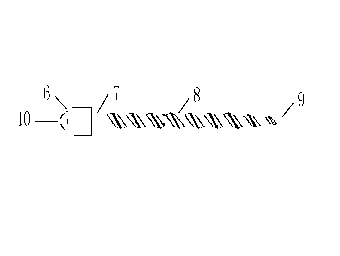

Embodiment 3

[0020] Embodiment 3: A number of carbon dioxide copolymers and additives are taken, and the composition parts by weight are: 100 parts of carbon dioxide copolymer, 10-50 parts of additives. After drying for 8 hours, the solid threaded bone nail is made by plastic processing methods such as mixing, granulation, extrusion and calendering, and punching, which can be used as a bone marrow fixation nail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com